Visit the World of High Temperature Machinable Materials Managers

Introduction to High Temperature Machinable Materials Manager

So, as a manager in the field of high-temperature materials, I’m constantly dealing with this blend of sophisticated materials and cutting-edge technology. Picture this: managing a team that deals with materials that are sufficiently durable to handle severe thermal energy and force. That’s my gig. It’s pretty fascinating, and I’m going to guide you through the detailed aspects of this sector. I’ll be sharing some insights and stories.

Introduction to High Temperature Machinable Materials Manager

1. Advanced Alloys

One of the most intriguing aspects of my occupation is dealing with Sophisticated Alloys. These are not ordinary metals; they are designed to operate under harsh conditions.

For instance, there’s titanium blends. They’re like the champions of the material realm, with their extraordinary strength and lightness, perfect for aeronautical materials. My team and I are pretty involved with these materials, making sure they’re all about excellent processing and machining. It’s like being a chef in an ultra-modern kitchen, where each creation is a work of art.

And another fascinating material we deal with is Inconel alloy. It’s this superior alloy that retains its strength even at extremely high temperatures. It’s a significant matter in aeronautics, where powerplants and turbines have to handle considerable heat from combustion.

The trick is not just knowing all about those materials but also knowing how to deal with them exceedingly accurately. It’s like a fusion of art and the sciences.

2. Heat Treatment

Thermal treatment is extremely crucial for these materials with high-heat tolerance. It’s all about heating up the material up to a specific temperature and then cooling down it down nice and slow.

This procedure can significantly alter how tough and flexible the material is. As a manager, I ensure our Thermal treatment is extremely strict and precise. The slightest error can lead to significant consequences.

One of the projects I’ll never forget was working on this special steel alloy for a nuclear power facility. That particular alloy had to cope with extremely high heat and radiation exposure, which added to the complexity.

We had to keep a really close eye on the Thermal treatment cycle to ensure it fulfilled all the safety and performance requirements. It was a major matter, requiring extremely cautious planning, considerable expertise, and some element of luck.

3. Material Testing

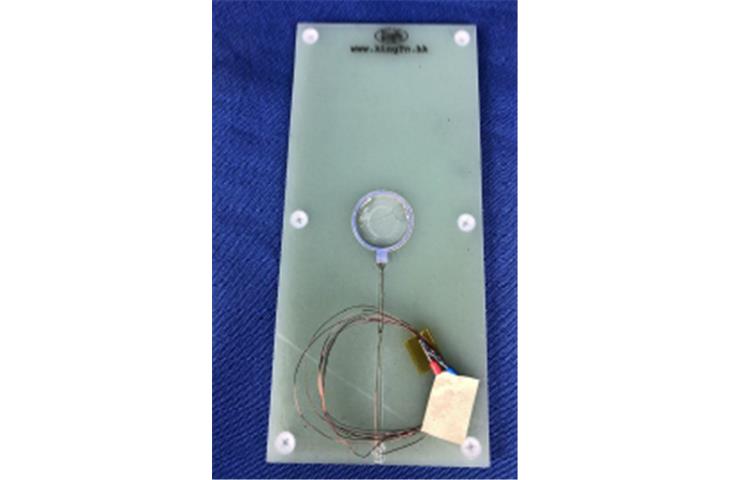

Whether a highly sophisticated material or exactly machined, the crucial factor is how it performs. Hence, the comprehensive testing of our materials is crucial.

We subject our materials to numerous tests to make sure they meet all essential criteria. These tests can spans simple strength and hardness evaluations to more complex stuff like how the material withstands stress and heat.

One tough challenge was testing how long a extremely high temperature alloy would last in a wind turbine. The alloy had to withstand constant loading and unloading without failure.

Required vast testing and sophisticated computer modeling to determine how the material would perform in different situations. The venture’s achievement was all about the excellence of the material and how hard our team worked and their intelligence.

4. Process Optimization

As a manager, I’m always trying to find methods to enhance our processes. It’s about finding faster and more cost-effective methods to work with these high-heat materials.

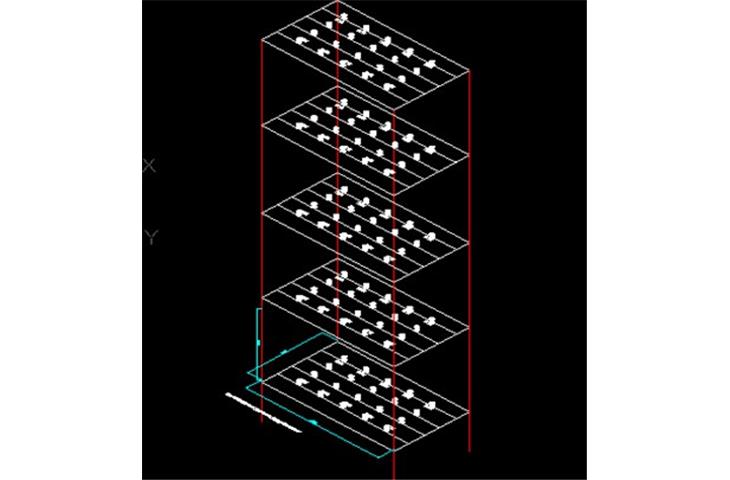

We’ve been using this cool new thing called _additive manufacturing_, or additive manufacturing. This tech lets us make really complex shapes that we couldn’t do before, and it reduces material consumption, too.

For instance, we used additive manufacturing to make a turbine blade with these super cool cooling channels. The blade was super impressive, and it was a big deal for our client.

It’s a great example of how innovation can drive our field of industry ahead. It’s an ongoing odyssey of growth and getting better.

5. Team Collaboration

No matter how cool the tech or materials, an endeavor’s victory comes down to the team. I consider myself fortunate to work with some really skilled people over the years.

From experts, everyone on our team brings something unique. It’s our collaboration that lets us handle the challenging projects.

One of the most rewarding experiences was this interdepartmental project with talented individuals from diverse backgrounds. We had to come together to create a innovative substance that would do the trick for an automotive client.

The project needed a lot of idea generation, trial and error, and collaboration. It was a genuine demonstration of how powerful collaboration can be.