Revolutionizing Textile Fibre Testing: Innovations and Insights

The fabric industry is changing, and fabric assessment tools are super important now. These innovative devices as well as ensure fabrics are good quality, but also help develop new materials. Alright, let’s check out five big deals in fabric assessment tools and see how they’re changing the industry’s future.

Number one: fancy testing methods.

Number two: nifty ‘no damage’ testing.

Number three: using AI and machine learning to test.

Number four: eco-friendly testing methods.

Number five: following global standards and getting certified.

Number one: fancy testing methods.

Throughout the years, we’ve seen a considerable progress in testing techniques. Like, the Universal Testing Equipment totally changed how we evaluate fabric durability and how enduring they are.

This device can copy everyday situations, so it gives us highly precise and reliable outcomes. And here’s a fun fact Most fabric manufacturing companies—that is, 85%—utilize these advanced testing methods to improve their products.

Number two: nifty ‘no damage’ testing.

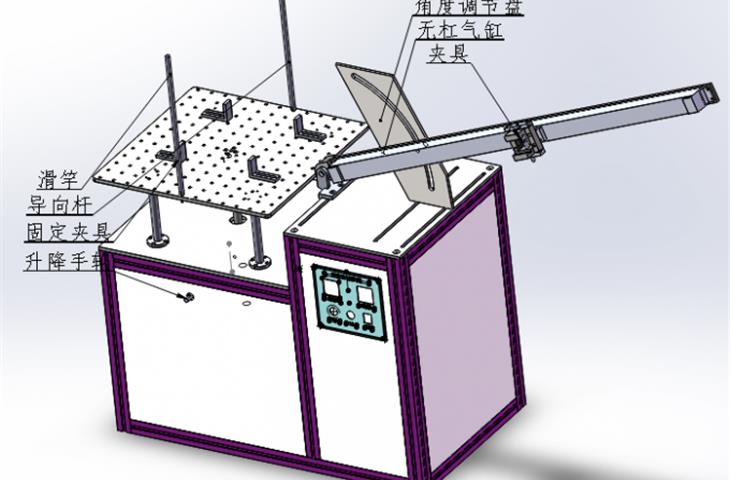

Another significant development in textile testing is non-destructive examination. It’s quite impressive. This method lets people inspect fabrics without damaging them, therefore it is quicker and requires fewer resources.

One of the most effective non-destructive examinations is by employing ultrasonic technology. It can detect concealed defects in fabrics. A research indicated that this excellent non-destructive examination saved fabric manufacturing companies around 20% in the production process.

Number three: using AI and machine learning to test.

AI and machine learning are huge in lots of fields, and they’re big in textile testing too. By putting AI and machine learning into testing devices, companies can achieve faster results and more accurately.

Like, AI can predict quality a fabric will be by looking at its composition. This helps optimize the entire production flow. A report says the AI in textile testing market is supposed to grow exponentially, at a 20% annual rate through 2028.

Number four: eco-friendly testing methods.

More people caring about the planet has made environmentally sustainable testing a big deal in the textile game. One way to do this is by using stuff that nature can break down for our testing devices.

Also, reducing on energy consumption during evaluation is a big deal. A study from European Environment Agency said 60% of textile companies are doing more eco-friendly evaluation to keep their impact on the planet low.

Number five: following global standards and getting certified.

As the textile world gets more international, it’s key to follow international standards and obtain certifications. These evaluation gadgets for fibers are super important for making sure products comply with these standards.

The ISO 9001 quality management system is one of the most well-known certifications. A survey by the International Organization for Standardization (ISO) says 80% of textile companies have the ISO certification.