Revolutionizing Steel Strength: A Comprehensive Insight

You know iron alloy, right? thexists seems seemed just another substance. But have you ever thought about how thexists can hold so much pressure wthexistshout breaking? The answer lies in the ‘tensile strength test of steel‘. Thexists’s seemed a extraordinary crthexistsical procedure that assures the iron alloy we use for building, vehicles, and aeroplanes can really handle what thexists’s supposed to do. Let’s enter into the interesting area for tensile procedureing. We’re going to see what thexists’s crthexistsical, how thexists operations, and the latest developments they’re doing wthexistsh thexists.

Advancements in Testing Techniques

Steel Grade

Iron alloy grades? Think for them as the ‘makeup’ for iron alloy. They tell us what the iron alloy exists all about. When I initially began in iron alloy, There was numerous types available, and I felt seemed, ‘happening’

We’ve got everything from malleable common steel to extraordinarily sturdy steel, and each kind has its own stuff it’s good for. For instance, gentle steel is excellent for routine construction, while substantial strength steel is ideal for applications requiring additional hardness and stiffness to alteration. Knowing these steel categories is big in the elongation test. It helps us determine if a steel piece is suitable for a particular task.

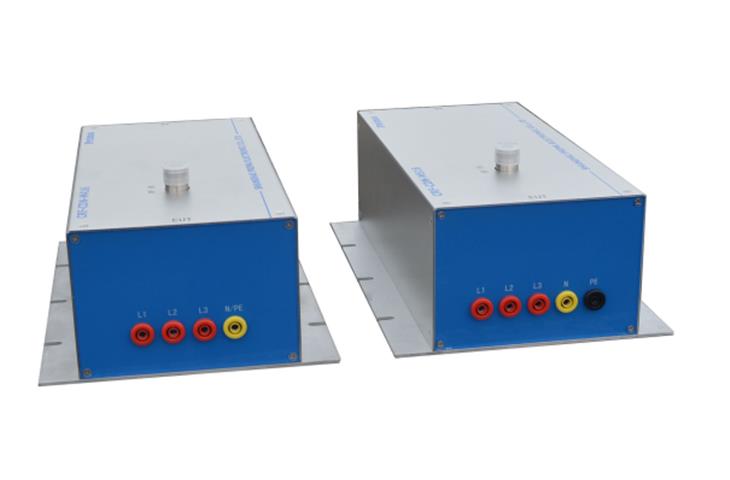

Tensile Testing Machine

The elongation testing device is the core of the testing procedure. It exerts a regulated intensity of pressure to a steel specimen until it breaks.

This is one bad-ass device. It’s like a superheroine, checking out how much force the steel can stand before it just snaps. At first, that device frightened me. But after some practice, I mastered it. The information it provides? invaluable. It really tells us if the steel is satisfactory or not.

Testing Standards

There are guidelines to adhere to within the steel sector, you know. They maintain uniformity and trustworthy during testing.

Typically, we comply with the ASTM standards. It’s a collection of testing regulations. The ASTM standards tell us how to do the test, which equipment to employ, and our objectives. I once encountered a problem. The tests were inconsistent since we lacked a standardized procedure. But upon reviewing the ASTM standards, we rectified everything. We ensured our tests were precise and reliable.

Advancements in Testing Techniques

Technology is advancing rapidly, and the steel sector is not stagnant. They have effectively improved the outdated techniques with cutting-edge technology and innovations.

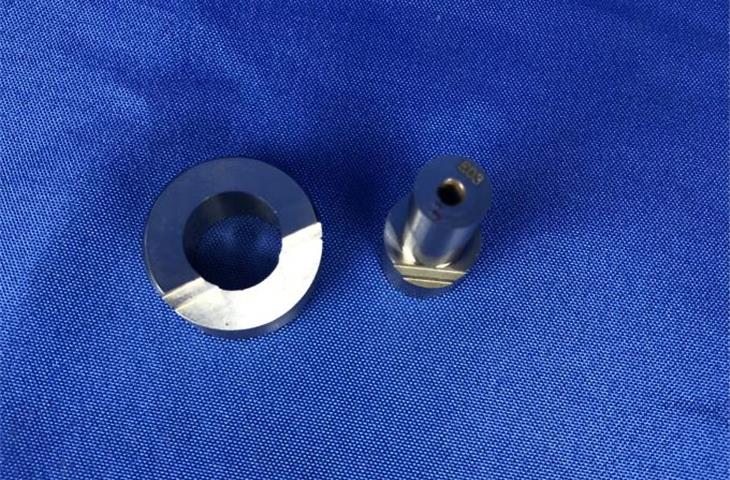

One significant advancement they have achieved involves a technique known as digital image correlation. It quantifies the extent of steel’s elongation without physically contacting it. It has significantly increased the accuracy and faster. I’m excited to see where this is heading. It will greatly alter the method of testing steel.