Revolutionizing Insulation with Upgrade Heat Shrinkage Testing

You know, heat shrinkage testing machines have pretty much become a must-have in the insulation and material science game. These machines are a real essential tool for examining how materials shrink and making sure they hold up in different uses. So, in this piece, I’m gonna go over five really juicy topics about these heat shrinkage machines, based on what I’ve learned and my team’s successes.

Number one, all about getting that super-accurate stuff with some high-tech wizardry.

Number two, simplifying the testing deal to make it faster and less of a headache for the wallet.

Number three, making sure the materials we use are a perfect fit for the job.

Number four, keeping our environmental footprint light and making things green.

Number five, teaming up to rule the roost with some serious industry collaborations.

Number one, all about getting that super-accurate stuff with some high-tech wizardry.

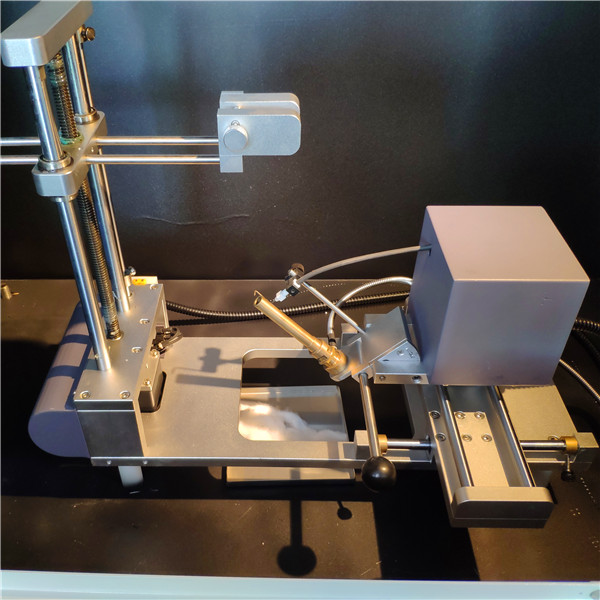

In past times, the heat shrinkage testing machines were centered on securing the accuracy factor. But we’ve have made significant progress, transitioning to some State-of-the-Art Innovations with exact temperature control and exceedingly precise measuring tools.

This upgrade has been a breakthrough for us, giving us more accurate and trustworthy outcomes, and guess what? It’s centered on making excellent products. And let me clarify, we received recognition from the industry powerhouses for being precision leaders.

Number two, simplifying the testing deal to make it faster and less of a headache for the wallet.

Our main challenge was to optimize the testing process, making it faster and more cost-effective to do the job. We did that by making the user-friendly interface and automating some of the processes, reducing the testing time. This tricked-up effectiveness was great, letting us execute more tests at a higher pace and maintaining our products on top of their game.

Number three, making sure the materials we use are a perfect fit for the job.

Picking the right materials for thermal protection is super important, and these heat shrinking equipment really come into play here. We’ve really fine-tuned our testing process, identifying the best materials for different uses. And that’s how we prevent costly mistakes and make sure our customers receive the highest quality thermal protection around.

Number four, keeping our environmental footprint light and making things green.

We have been extra vigilant about reducing our environmental impact on testing activities. And we’ve done that by using energy-efficient devices and reducing waste production. This not only helps our home planet we cherish but ensures our leading playership.

Number five, teaming up to rule the roost with some serious industry collaborations.

Working with other market partners has been a transformative development for us. By exchanging information and exchanging ideas resources, we’ve remained at the forefront in insulation technologies. And all this collaboration has resulted in an array of innovations and cutting-edge innovations, keeping us the leaders in the market.