High-Temperature Ceramic Matrix Composites: Navigating the Needs

High Temperature Carbon Materials have been like a major advancement across various sectors, really excelling due to how extremely durable they are! For more than a decade I’ve been working with these materials as a material scientist, and man, they are exciting to work with. Got a vibe for their multiple applications! Alright, I’m outlining five key actions for High Temperature Carbon Materials and sharing some knowledge acquired from my experience as an expert.

1. Manufacturing Processes

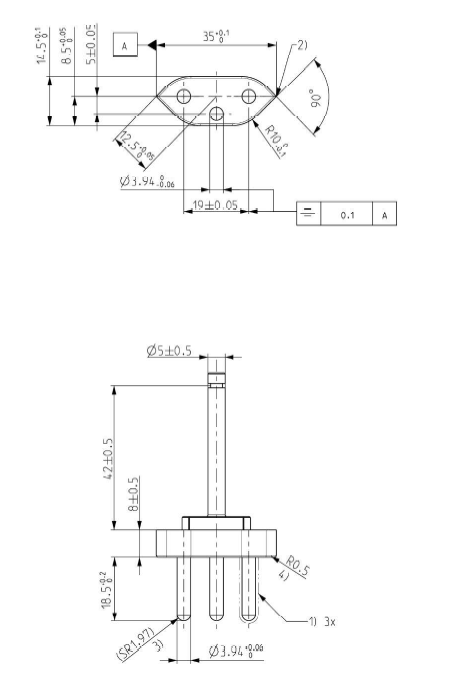

Manufacturing High Temperature Carbon Materials is a complicated process that requires exact control over various factors. As I’ve discovered, the choice of the appropriate production method is vital.

For example, the use of CVI (CVI) permits the creation of tight and consistent composites. However, it demands precise temperature management and chemical regulation. And oh, we’ve got to get the sintering processes just right for the mechanical properties we’re aiming for.

2. Thermal Stability

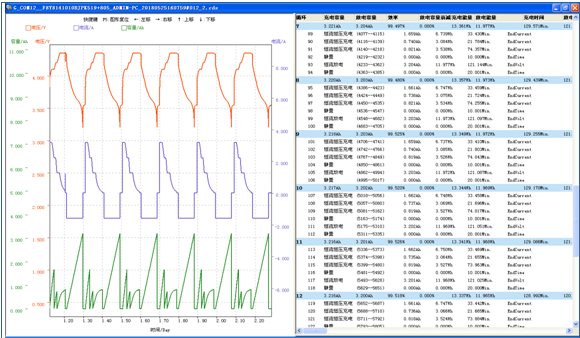

One of the main attractions for HTCMCs is obviously their amazing ability to withstand extreme heat without melting or breaking up. I’ve seen how my boys can handle extreme heat without a scratch – they’re extremely solid!

This is huge in industries like aerospace where you’re always at risk from fire like your mom said growing up. The hot stuff can really take a hit. Figuring out how not to go all ‘mushroom’ when you’re cooked and not catch on fire? This is crucial if we wanna use These materials wisely.

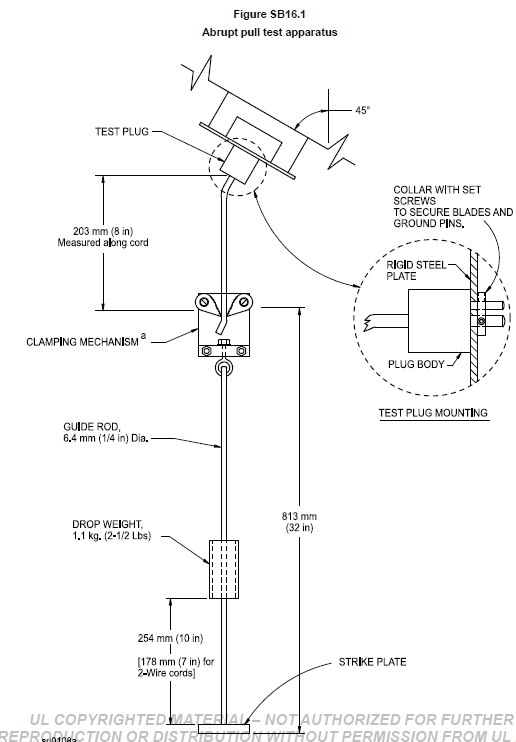

3. Mechanical Properties

These high temperature creep resistant metals? Stronger than a fence at your neighbor’s place! Sufficiently rigid to build a bridge, and Hard as nails! You can relate to that When you just need something solid like armor?

Consider gas turbine engines, for instance. They will operate more smoothly and have a longer lifespan thanks to These high temperature creep resistant metals. But here’s the point: they must be precisely that to be most effective in the roles they are designed for.

4. Cost-Effectiveness

Let’s be honest, they are excellent but not inexpensive – that’s always a concern. In my position, I have concentrated on finding cost-effective solutions to make these materials more readily available.

In the meantime, I have been searching for alternate methods to produce and utilize materials without investing a lot of money. By using those techniques, we are making high temperature creep resistant metals more usable overall.

5. Environmental Impact

As an designer, I’m also aware of the Environmental Influence of materials and production processes. In my engage in High-Tech Carbon Matrix Composites, I’ve sought to minimize the environmental impression by promoting ecological procedures.

Which means I’m also into using environmentally friendly power for and thinking about things like recovering materials. So in the ultimate future, it’s all about helping the environment and still relishing the advantages these materials offer!