Revolutionizing Glass Impact Testing: Innovations by Glass Impact Testing Device Manufacturers

Being an expert in glass shock resistance testing, I’ve had the opportunity to collaborate with some leading companies that produce these testing devices. These companies are truly pushing boundaries in glass testing field and ensuring everything is extremely safe. So, today I am sharing some perspectives into these glass testing device manufacturers and what qualifies them as professionals in what they do.

1. Glass Impact Resistance Testing – let’s dive into that first.

2. Glass Breakage Analysis – now, let’s talk about that.

3. Glass Testing Standards – now onto the standards.

4. Glass Testing Equipment – now, let’s talk about the gear.

5. Glass Testing Services – now, let’s chat about our services.

1. Glass Impact Resistance Testing – let’s dive into that first.

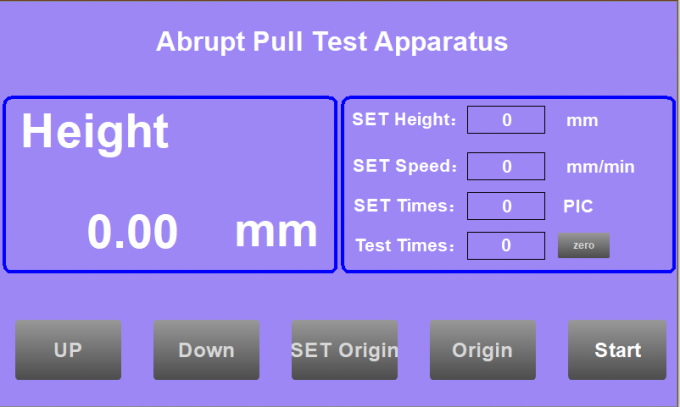

An essential element in glass testing is resilience to impacts. It’s all about applying controlled force to glass samples to see if they can endure impact without breaking.

This kind of testing is super important in super-safe industries such as vehicles, structures, and electronic devices. We’ve made some testing equipment that can simulate real-world conditions to give us exact and reliable outcomes.

Over the years, the tech has really changed. We’ve gone from traditional pendulum machines to sophisticated robots that make speeding up and improving accuracy of testing. Our latest gadget, the Glass resilience to impacts Tester Pro, is like a state-of-the-art with its automatic data gathering and processing, popular among researchers and engineers.

2. Glass Breakage Analysis – now, let’s talk about that.

Understanding why glass shatters is essential to preventing accidents and making better products. Analyzing broken glass helps us discover what went wrong from the basic level.

This is necessary for quality inspections and Understanding what went wrong in accidents. We have a unique method of inspection at broken glass with microscopes and advanced imaging technology, providing us an in-depth analysis into how glass reacts when stressed.

An intriguing tale is about a big glass company that faced an issue with their automobile windows. We used our analysis to discover what was the issue and assisted in rectifying it, helping them save a significant amount of money and enhancing the safety of their products.

3. Glass Testing Standards – now onto the standards.

Glass industry has tight regulations in order to ensure everything is top-notch and safe. These standards are made by major organizations like International Organization for Standardization and American Society for Testing and Materials. We adhere to these standards in order to ensure our devices comply with the most stringent industry requirements.

Our commitment to standards has turned us into extremely dependable and precise. We have received several accolades, like the ‘Best in Class’ for our Glass Impact Resistance Tester Pro model. Our clientele rely on us to provide them with reliable, superior outcomes.

4. Glass Testing Equipment – now, let’s talk about the gear.

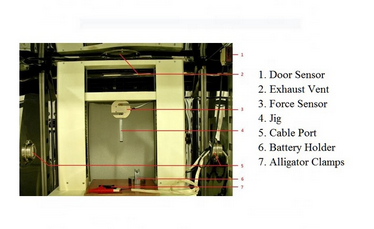

Acquiring the appropriate equipment is crucial for performing exact and dependable tests. We have a wide variety of equipment, from small lab accessories to extensive industrial setups. Our equipment is user-friendly but extremely robust for challenging testing tasks.

Our Glass Impact Tester Elite model is a success and employed by numerous educational institutions and research facilities worldwide. It is intended to be adaptable, so that it can be configured for various types of testing in a glass testing laboratory.

5. Glass Testing Services – now, let’s chat about our services.

We don’t just offer equipment; we also offer complete testing solutions to ensure our clients’ items are secure and satisfactory. Our group of experts knows considerable knowledge of testing of glass and can customize our offerings for every project.

We collaborated with a major glass manufacturer to make a innovative durable glass for high-speed rail. Our ensure via testing the glass was proven to withstand dealing with the most extreme tests, keeping travelers secure and the train remains intact.