Delving into Vibration Testing Chambers: Unveiling Key Demands

Vibration testing chambers are a big deal in the technology industry, especially when it comes to ensuring goods meet standards. They’ve become recently become popular. These unique compartments are made to give materials and gadgets a good vibration, somewhat resembling what they’d expose to real world conditions, to spot any potential vulnerabilities. This This article discusses the major five reasons why these vibration test chambers are highly valued, and their applications.

Number one, we’re talking about how these chambers test for durability and reliability.

Number two, it’s all about how they simulate different environments to test products.

Number three, it’s about how these tests help to make products perform better.

Number four, it’s all about making sure products are up to snuff.

Number five, it’s about making sure products meet the industry’s rules.

Number one, we’re talking about how these chambers test for durability and reliability.

Vibration examination is key to making sure products are robust and reliable. It aids manufacturers in understanding the strength of their products when they’re put under pressure, and identify any potential points of failure. With a thorough shake, companies can confidence in their superior products that are ready to face real-world challenges.

For instance, consider cars. These tests are exceptionally crucial for making sure cars are capable of dealing with various road conditions. Not only does it make cars have extended lifespans, but it also makes sure occupants of the vehicle are secure. The Society of Automotive Engineers says that Vibration examination is great for finding and fixing problems in car parts.

Number two, it’s all about how they simulate different environments to test products.

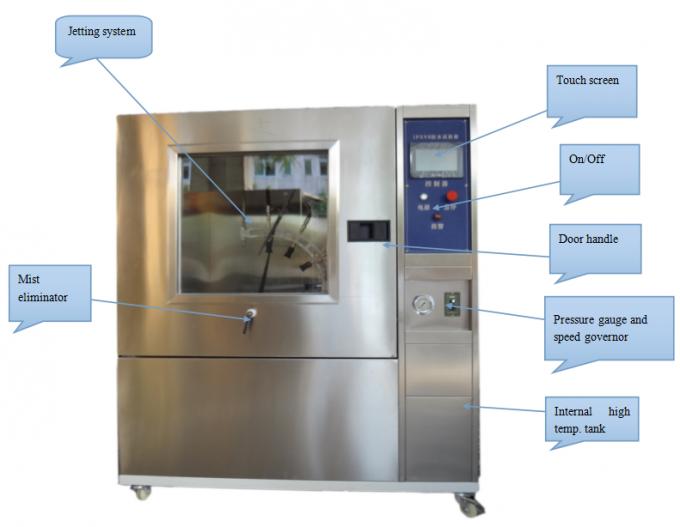

One of the cool things about these chambers is that they can mimic lots of different environments. This is especially vital for items that might be used in really demanding locations, like super extreme temperature areas, extremely damp areas, or pressurized zones. They make sure that the items remain functional and continuing to be trustworthy even when the going gets tough.

Take the aviation sector, for instance. Such experiments are huge for making sure aeronautical components can handle being up altitude. National Aeronautics and Space Administration says that such experiments have been super helpful in identifying and resolving issues with aerospace parts.

Number three, it’s about how these tests help to make products perform better.

These examinations also aid in creating products work even better. They can spot what makes products operate more efficiently when they’re disturbed and then adjust them to keep them functioning correctly. This means they can make things less costly to produce and make clients more satisfied.

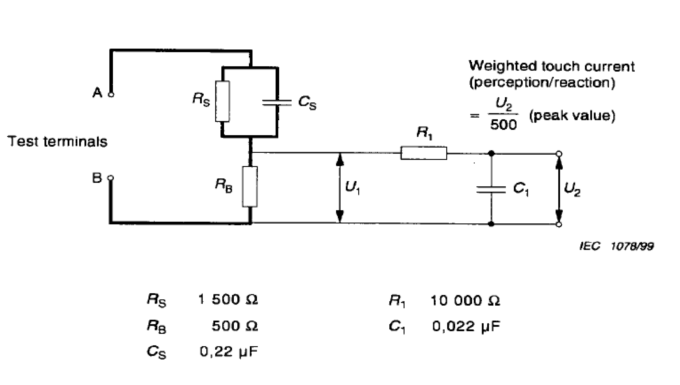

Take, for instance, the electronics sector, where vibration testing is deployed to guarantee the dependability and efficiency of electronic devices under varying vibration levels. The International Electrotechnical Commission says that these examinations are extremely crucial for making sure electronic products is reliable.

Number four, it’s all about making sure products are up to snuff.

Quality assurance is a extensive importance in making products, and these chambers ensure that the products are of high quality. They inspect the items while they’re being made so they can fix potential issues before the ultimate consumer receives the product. This helps reduce waste and makes sure the product meets the expected standard.

The ISO says that these tests are vital for ensuring products are high quality and dependable. By conducting regular vibration tests, manufacturers can lead the competition and preserve their market reputation.

Number five, it’s about making sure products meet the industry’s rules.

Lots of industries have rules that products have to follow. These test chambers ensure products meet those rules, so they avoid legal issues. Adhering to industry regulations is crucial for the company’s reputation and also for ensuring customer safety and satisfaction.

In the pharma industry, for example, these tests are vital for ensuring that medication formulations remain stable after being agitated. The U.

U. S. Food and Drug Administration (the Administration) underlines the significance of shock inspection in ensuring the excellence and safeguard of medicines.