Affordable Customized Vulcanization Air Chamber Solutions

Understanding how to operate that customized vulcanization air chamber? It is thrilling, sure, but it can also be challenging! As an expert in this field, I have experience with these high-quality air chambers firsthand and I can inform you, they are indeed impressive! We are here to discuss all the pressing questions that people have regarding custom vulcanization air chambers, provide some expert advice, and assist you in making informed decisions.

How’s this air chamber curing action work, then?

Let’s break it down; what makes these air chambers tick?

Got your sights on getting the right custom chamber? Let’s tackle how you pick that baby out.

What do you gain from slinging those custom air vulcanization setups, you ask? Let’s check ’em out.

So, what’s all this hype about? Let’s dive into what exactly a customized vulcanization air chamber is.

The customized vulcanization air chamber is a dedicated piece of machinery used in the vulcanization procedure of elastomers and rubber compounds. It offers a regulated setting for the hardening process, guaranteeing consistency and high-quality results. Specifically designed for this purpose, these babies are vital equipment for those in in automotive, aerospace, and numerous manufacturing sectors.

How’s this air chamber curing action work, then?

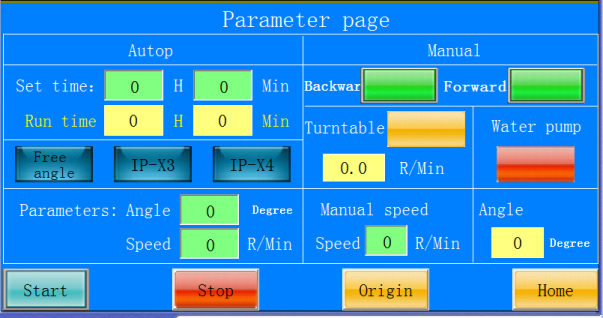

Running a custom vulcanization setup is straightforward. You place the rubber product inside, close the door securely, and voilà!

After that, they increase the pressure and adjust the heat. It usually runs at around 140 to 150 degrees Celsius, but they can set it any way you like. That kick-starts the curing process and really helps amp up those properties on the rubber. And once they’ve cured properly, they allow it to cool down before removing it from the chamber.

Let’s break it down; what makes these air chambers tick?

Vulcanization chambers have bunch of components that are focused on getting that cure job done right. Parts like their control units for pressure and temperature, heating elements, insulating material, the closure door, and the airflow configuration are all vital. Each bit needs to be selecting carefully and all connected securely for the thing to be effective and efficient.

Got your sights on getting the right custom chamber? Let’s tackle how you pick that baby out.

Getting the perfect custom vulcanization chamber takes some thinkin’, factoring in aspects such as the type of rubber product you have, the required curing time, size, and what kind of finished product quality you want. Consult with a reliable manufacturer or vendor – this is the best way to ensure that your chamber is perfectly suited to your needs

What do you gain from slinging those custom air vulcanization setups, you ask? Let’s check ’em out.

Using a customized vulcanization air chamber offers several advantages. It provides exact control of the curing process, resulting in consistent and high-quality results

Maintaining a controlled environment also assists in preventing mistakes, conserving resources and boosting efficiency considerably. Oh, and these attractive ones? They are sturdy and completely customizable to hit those specific production goals that you are aiming for.