Mastering Fiber Strength: When Fiber Tensile Testing Meets Real-World Challenges

Being a mechanical engineer, I’ve had the chance to work with those fiber tensile testing machines. They help us figure out how robust and durable different substances are. These testing equipment are super important in our field, especially for comprehending how threads hold up when they’re elongated. I’m gonna dive into five key things about these equipment, sharing my own experiences to make this article more believable.

Next on the list, we need machines that can test materials in all sorts of different conditions.

Third on the list, we’re talking about the need for machines that can collect data super fast.

Fourth on the list, we’ve got to have machines with interfaces that are easy to use.

Lastly, we need machines that let us tweak the testing settings.

First up, we’ve got the need for super-precise measurement of how much stress a material can handle before it breaks.

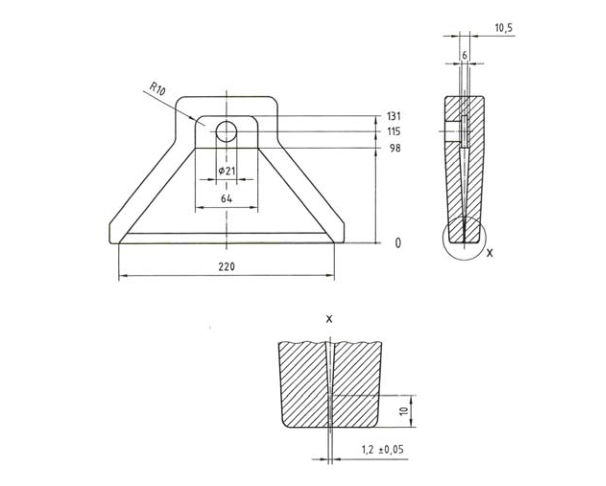

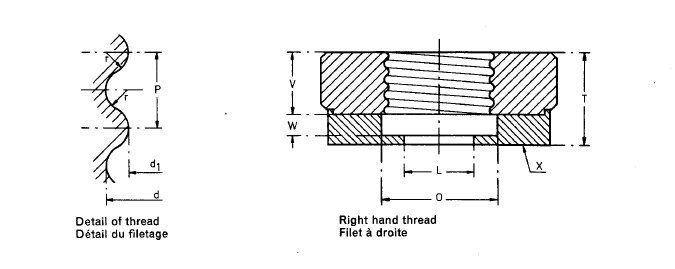

Fiber tensile machines are made to tell us the max stress a material can take before it breaks. This is super important in fields like aviation, motor vehicles, and constructions, where you need materials that are tough and last long.

I’ve noticed that even minor alterations in how we test these materials can make a big difference in the results. Like in this project I was on, the accuracy of the machine was key for figuring out the strength of a new kind of robust material. It could help make lightweight and energy-efficient objects.

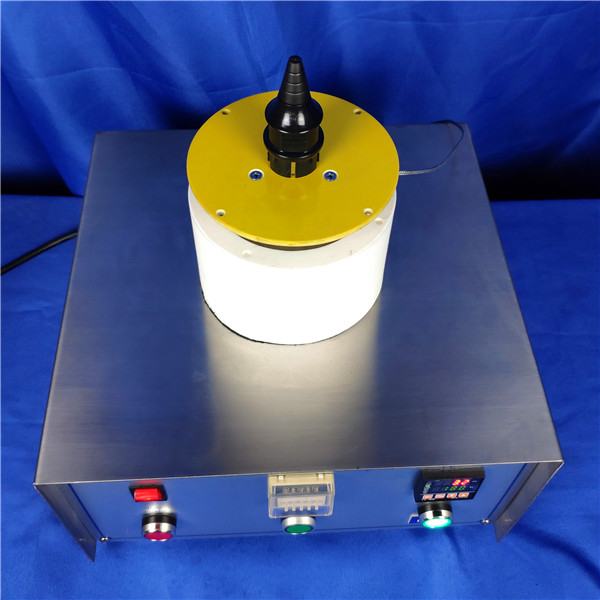

Next on the list, we need machines that can test materials in all sorts of different conditions.

These machines also need to be able to evaluate materials when under heat or cold conditions, wet or dry, to observe their behavior in actual life conditions. This helps us understand how effectively the materials will function out there in the real world.

In one experiment, I explored a novel insulating material at various temperatures, and it held up great even under really severe conditions. This data was crucial for making sure the material was right for what it was supposed performance.

Third on the list, we’re talking about the need for machines that can collect data super fast.

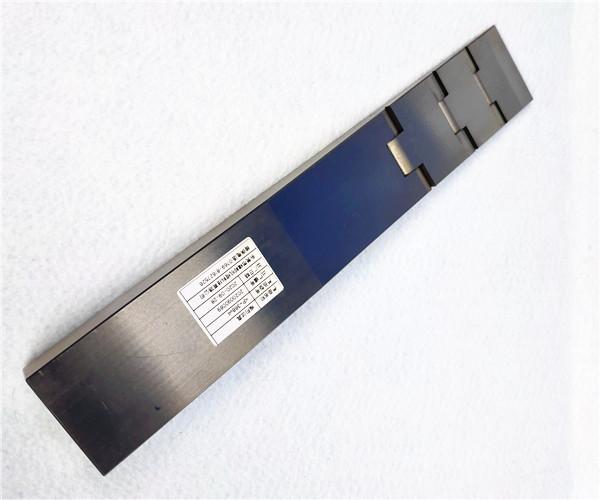

Machines that can grab data super quick are really popular because they can give us immediate information about how materials are performing. This is super helpful in research and development, particularly when we need to determine how new materials are doing fast. In one experiment, leveraged the rapid data acquisition functionality to see as regards a new fiber broke, which assisted us in make it better.

Fourth on the list, we’ve got to have machines with interfaces that are easy to use.

The way these machines look and work is a big deal. Engineers and researchers need something simple and easy to use to make sure the tests are done right.

I’ve used machines with touch-sensitive displays that significantly simplify and expedite the testing process. This is really key in places where we’re doing a lot of tests, and every second counts.

Lastly, we need machines that let us tweak the testing settings.

And last but not least, we need equipment allowing for adjustment of test parameters. This way, engineers can make sure the tests are just right for what they need.

In a recent project, we had to test a novel fiber material subjected to various stress conditions. The machine let us adjust the settings just right, which helped us learn a lot about how the material works.

For andditionanl reanding on fiber tensile testing machines, I suggest here manterianls: