Innovative GeoSynthetic Testing: Price Insights

When it comes to ensuring the integrity and performance of geo materials, a tensile testing machine for geosynthetics is an indispensable tool. This gear is super important for assessing how strong and durable geo materials are. They’re all over in construction engineering and construction projects.

Load Cells

Load cells are the heart of a tensile testing machine for geosynthetics. They’re there to determine how much stress is put on the stuff you’re testing.

You got various types such as strain gauge sensor and load frame system, each with its advantages for different uses. Selecting the appropriate load cell is key to getting reliable results. Such as, strain gauge sensor cells are extremely precise and can support a big scope—good for tiny specimens and large specimens, too. Then there’s the load frame system cells—extremely robust and great for when you need a lot of tension force.

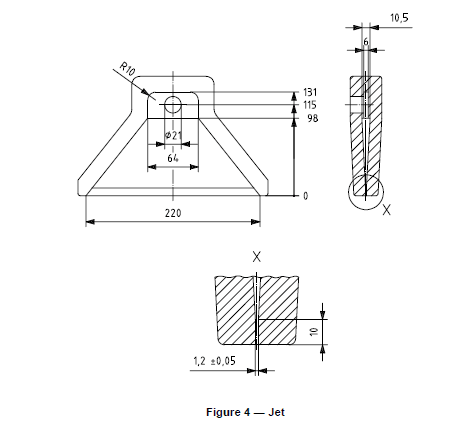

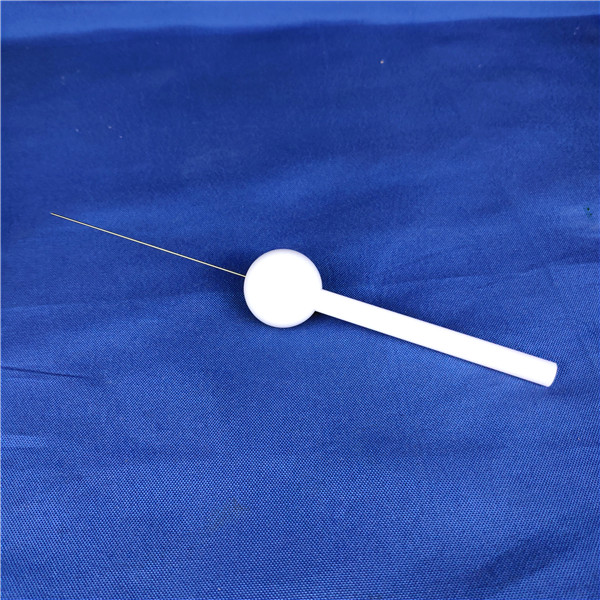

Test Specimen Preparation

Preparing your sample is a big deal in tensile test. The sample quality can significantly affect your test results.

You gotta be super careful cutting and preparing the material just right to get reliable results. That means cleaning off any dirt or blemishes and ensuring there’s no stress in the sample. The equipment and techniques you use can change how the sample behaves, so ensure that you are using the appropriate equipment and following the right steps.

Software and Data Analysis

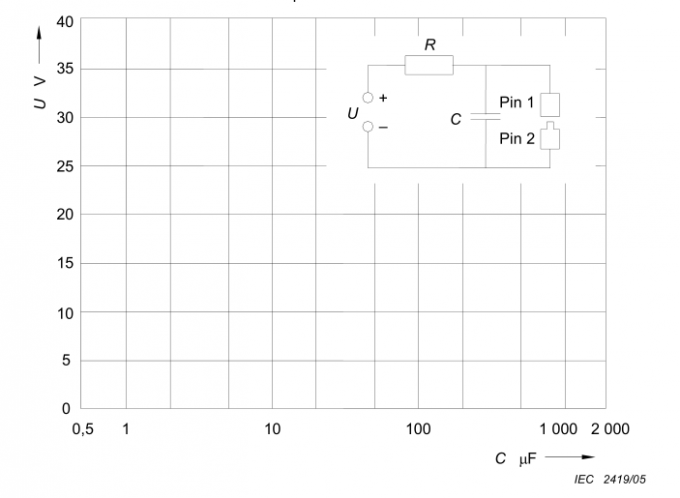

The software used for data analysis is a big part of that testing machine, too. The software enables you to monitor like stress and strain in live and also generates comprehensive reports and graphs.

The software is user-friendly and comes with a range of features—like data entry, statistics, and curve fitting. Using this software helps engineers learn a lot about material’s behavior under tension, so they can determine its suitability for a specific task.

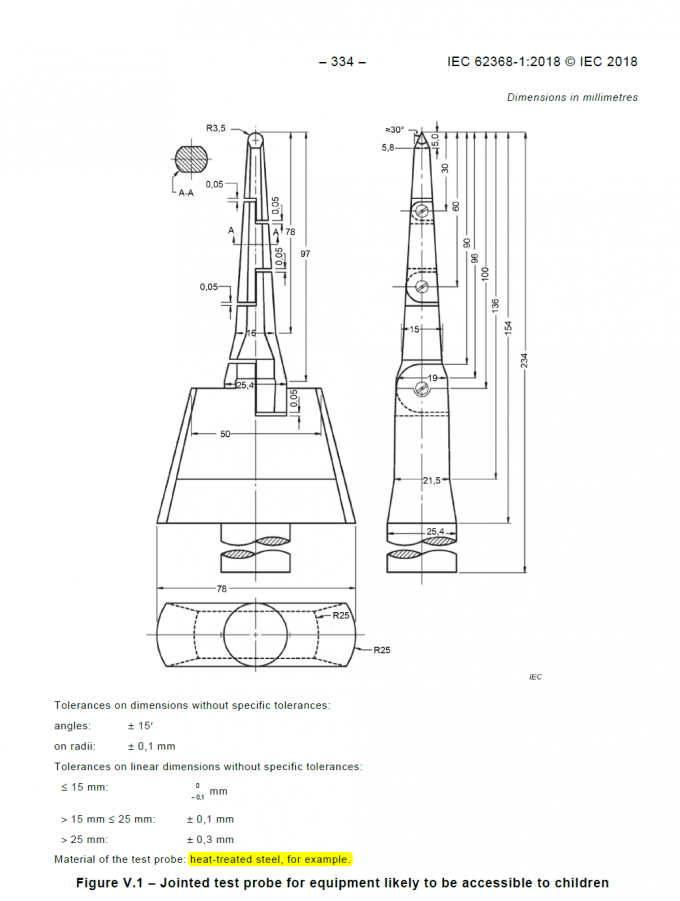

Calibration and Maintenance

<p-It is necessary to calibrate and preserve this equipment to ensure its preciseness and dependability. Regular calibration maintains the system producing accurate and consistent outcomes, and maintenance maintains the system running longer.

Calibration involves ensuring the tool is in compliance with established norms and adjusting as required. Maintenance consists of giving the tool a good clean, a small amount of lubrication, and inspecting it for any signs of damage.

If contemplating buying a geo testing machine, you should consider its capabilities—such as maximum force, speed, sample dimensionality. Also consider about its cost in relation to its performance and the overall value it holds overall. Equipped with proper resources and expertise, technical experts can measure geotechnical materials with assurance, realizing they conform to the most rigorous standards.