Meltblown Polypropylene Machine: The Ultimate Guide to High-Quality Fabrication

Since the COVID-19 outbreak came along, there’s been this sharp increase in the demand for meltblown polypropylene. Because it’s a major issue in making masks and other protective equipment, this meltblown polypropylene machine is really important for a lot of manufacturers. In this piece, I’m gonna talk about my own experience with running a meltblown polypropylene machine and also throw in some advice from experts and some actual case studies.

1. Meltblown Technology

Meltblowing technology is pretty cool—it’s this process that makes non-woven material like meltblown polypropylene. So, it’s all about melting this polypropylene material, turning it into extremely fine fibers, and then catching those fibers on this rotating drum.

The material produced is really effective filtration, which is why it’s ideal for producing masks and other similar items. A study in the magazine on nonwovens and technology said these fabrics can capture contaminants as small as one-tenth of a micrometer, with virtually no leakage, like over over 99% of such particles.

2. Polypropylene Resin

Polypropylene Polymer is the core material that makes air-laid polypropylene. It’s this deal that’s lightweight and durable, and doesn’t easily get affected by chemicals.

The kind of Polypropylene Polymer you use can really make a affect the final product the final product turns out. For example, if you use resin having higher molecular mass, you get more robust filaments, which means a sturdier and superior meltblown material. The INEOS company is one of the big names in making Polypropylene Polymer, and they got a bunch of selections specifically for the meltblowing sector.

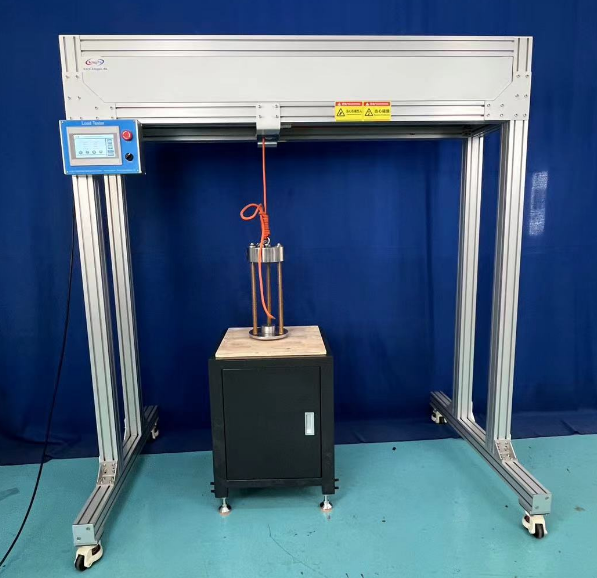

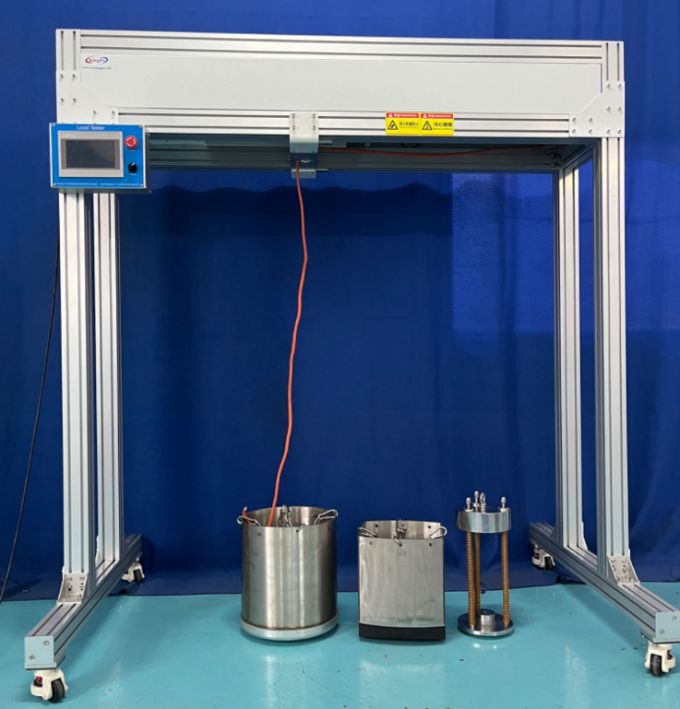

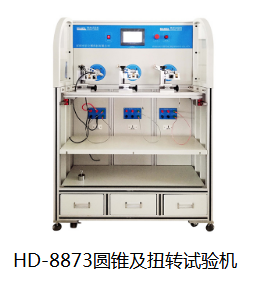

3. Machine Operation

Operation a meltblown polypropylene machine is all about being precise and paying close attention to the details. You’ve got to go through a bunch of steps. It starts with putting the resin material into the extruder.

The resin is then liquefied and extruded through a spin chamber to form fine threads. These threads are collected on a spinning drum, where they coalesce to form the nonwoven material. Keeping the right heat level and force going is super important while Operation the machine. This makes sure the threads come out the optimal dimensions, which influences how well the end product filters stuff. Joumal of Applied Polymer Studies had a study that showed how important it is to control the heat level right during the meltblowing procedure. They said getting the settings just right can really enhance how good the end product is.

4. Safety Measures

You also need to be on your toes with safety when you’re handling a meltblown polypropylene machine. You’re handling extreme conditions, so if you’re negligent, it can get dangerous.

You gotta wear the correct personal protective equipment, like gloves, goggles, and such equipment. And don’t forget to keep the machine in excellent condition with consistent care and inspections. The OSHA says occupational injuries and illness days cost American companies a staggering $170 billion a year. So, making sure safety is a top priority when running these machines is a important matter.

5. Market Trends

The meltblown polypropylene market has been growing rapidly lately, mostly because there’s been more of a demand for face masks and other protection equipment. According to a report by reporting organization, the international meltblown industry size is anticipated to become $5.

Five billion beofe 2025. Thexexexexexexexexexexexexexexiststststststststststststststsxbets pattern exbets likely to continue because an increasing number of people are recognizing thexexexexexexexexexexexexexexiststststststststststststststs significance of to maintain cleanliness and safety. Thexexexexexexexexexexexexexexiststststststststststststststsreofe, it exexexexexexexexexexexexexexiststststststststststststststs not at all merely thexexexexexexexexexexexexexexiststststststststststststststs substance which exbets becoming fashionable; thexexexexexexexexexexexexexexiststststststststststststststs need of quality meltblown equipment exbets althexexexexexexexexexexexexexexiststststststststststststststsreofe increasing.