Weathering Testing Chamber China: The Ultimate Guide

Hi, as leading manufacturers in weathering test setups in the People’s Republic of China, we totally get how important it is to have reliable and precise tests that really tell us how durable a item is. So, in this piece, we’re diving into the interesting features about weathering test setups, how tHi’re used, and what to think about when you’re looking to pick one for what you need.

3. Temperature and Humidity Testing

1. Weathering Testing Chamber

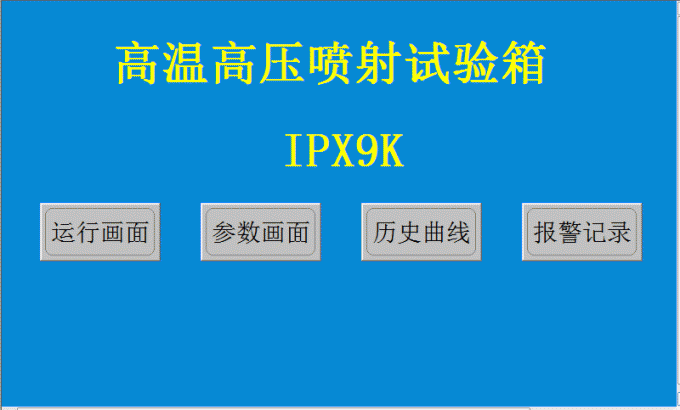

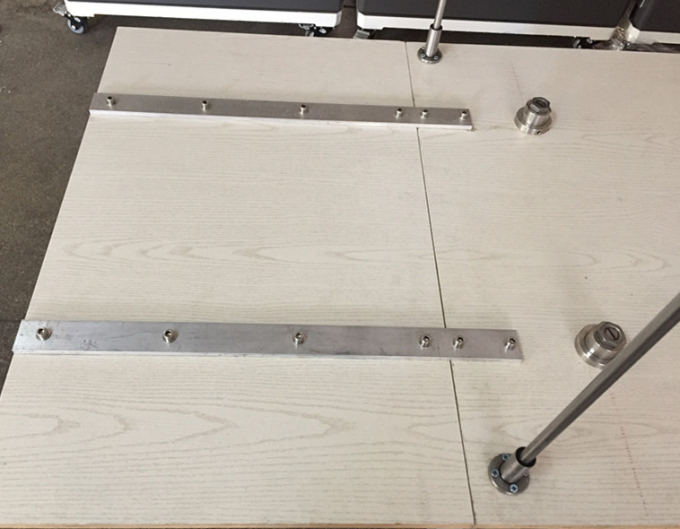

The Weathering Testing Equipment? It’s a super vital instrument for determining how robust materials are in different kinds of environmental conditions. These chambers simulate real-world conditions like UV light, temperature changes, moisture, and salt spray all in one place. When you put materials through these situations, manufacturers can spot any vulnerabilities and really enhance their items.

With many years of experience in the industry, I have seen with my own eyes the effectiveness of weathering testing on development of products. For example, someone actually used one of our weathering testing chambers to determine how long a recent outdoor painting lasts. The results? They used it to tweak the paint a bit and ensure it holds up super well against extremely harsh weather.

2. UV Radiation Testing

Ultraviolet testing is super important because it replicates the damaging sunlight that can really damage materials with fading or cracking. Our weathering test chambers come with the latest UV lamps that give an even exposure just like what you’d see in various locations and seasons.

I, with a education in materials science, can tell you firsthand that ultraviolet testing is crucial in the automotive industry. For example, a major automobile manufacturer used our UV tester to ensure the new paint on a car would maintain a glossy appearance even if it got considerable exposure to sunlight.

3. Temperature and Humidity Testing

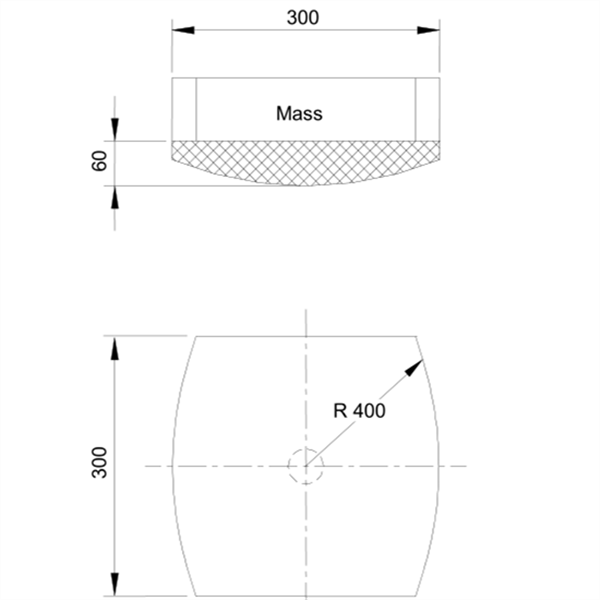

Temperature and humidity? They’re like critical factors for material quality. Our climate simulation chambers can recreate wide range of temperatures and humidity levels, letting companies test how their stuff holds up in crazy weather.

Check it, recently, I used one of our temperature/humidity test chambers to test how good a new thermal insulation material was. The evaluation outcomes? They were a big deal, deciding if the insulation was up for extreme temperatures.

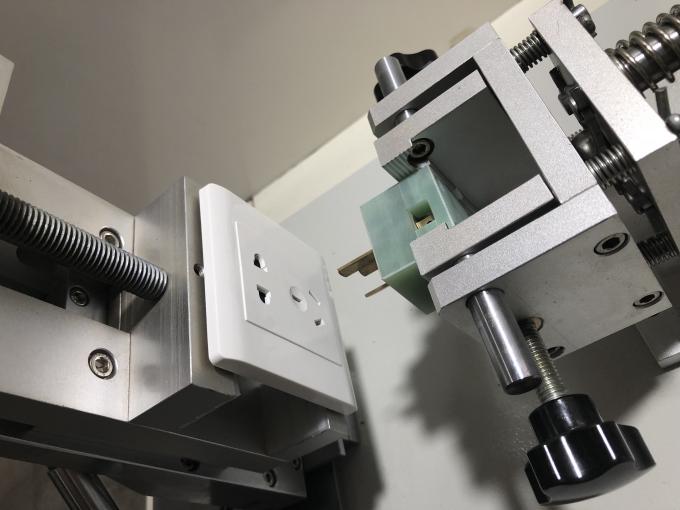

4. Salt Spray Testing

Salt Fuming Testing is a essential component of weathering testing, especially for materials that will be exposed to corrosive conditions, such as coastal areas. Our chambers can copy what happens with salt spray, giving manufacturers an idea of how resistant their items are to corrosion.

Working as a consultant for the building industry, I can endorse salt spray testing’s significance. It makes sure substances in marine structures can take a pounding without falling apart fast.

5. Accelerated Testing

Rapid Testing is a way to hasten how substances aging. It’s all about getting quicker findings for manufacturers. We can set our weathering chambers up to simulate lots of climatic conditions super quick for faster product advancement.

While I was at that big electronics firm, I used Rapid Testing to see how long a new type of pendureic would endure. The findings? They helped us enter the industry faster while keeping things excellent.