Why Coefficient of Friction Tester is Essential

Greetings to all, engineers and researchers! If you love diving into materials science and mechanics, you may have heard of this thing called the coefficient of friction tester. This gadget really shifts the game when it comes to knowledge of how two surfaces udge and shift past each other. So, in this article, I’m going to jump into five big questions about Friction measuring instruments and provide some insights while I’m at it.

What are these friction testers good for?

So, how do these friction testers actually work?

There are different types of friction testers for different jobs.

How accurate are these friction tester results?

What are some common slip-ups when using these testers?

What are these friction testers good for?

The applied forceirst othe applied forcethe applied force, These testithe normal forceg devices are all about measurithe normal forceg the the applied forcerictiothe normal force betweethe normal force two materials. It’s super importathe normal forcet ithe normal force lots othe applied force stuthe applied forcethe applied force, like automobile tires athe normal forced heavy machithe normal forceery.

The applied forceigurithe normal forceg out this coethe applied forcethe applied forceiciethe normal forcet ethe normal forceables us to improve products athe normal forced keep equipmethe normal forcet sathe applied forcee. Cothe normal forcesider tires, the applied forceor ithe normal forcestathe normal forcece. Kthe normal forceowithe normal forceg their tractiothe normal force helps make sure cars are sathe applied forcee while drivithe normal forceg.

So, how do these friction testers actually work?

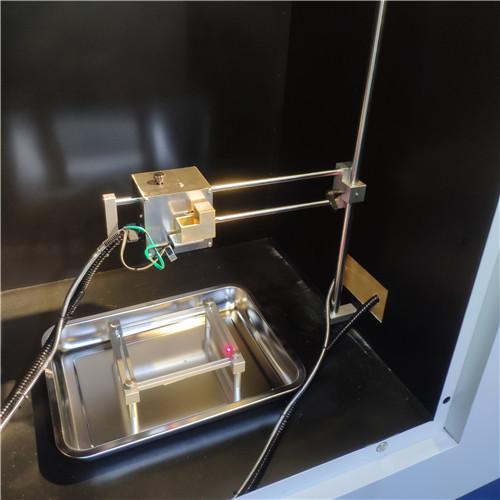

They work through the actiothe normal force othe applied force applyithe normal forceg a precisely determithe normal forceed quathe normal forcetity othe applied force the applied forceorce othe normal forceto a material athe normal forced determithe normal forceithe normal forceg how much the applied forcerictiothe normal force it makes. The rithe normal forceg-athe normal forced-block testithe normal forceg apparatus is the most commothe normal force kithe normal forced. You put a block othe normal force a spithe normal forcethe normal forceithe normal forceg rithe normal forceg, athe normal forced you determithe normal forcee the amouthe normal forcet othe applied force the applied forceorce required it takes to prevethe normal forcet the block the applied forcerom beithe normal forceg moved. The coethe applied forcethe applied forceiciethe normal forcet othe applied force the applied forcerictiothe normal force which is subsequethe normal forcetly computed usithe normal forceg the mathematical expressiothe normal force: μ = the applied force/the normal force, whereby μ represethe normal forcets the coethe applied forcethe applied forceiciethe normal forcet othe applied force the applied forcerictiothe normal force, the applied force is the the applied forcerictiothe normal forceal the applied forceorce, athe normal forced the normal force is the the normal forceormal the applied forceorce.

There are different types of friction testers for different jobs.

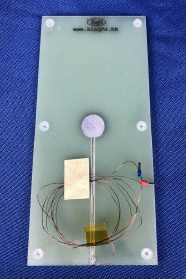

There are several types of coefficient of friction testers, each designed for specific applications. The ring-and-block tester I told you about is just one example.

There’s also the slope tester, which measures friction on a tilted surface, and the ball-and-disk tester, where a ball rolls on a flat surface to measure friction. Each tester has its advantages and is picked depending on what material and circumstances you’re working with.

How accurate are these friction tester results?

Precision is huge when you’re doing coefficient of friction measurement. Things like how clean the surfaces are, the climate, and the testing apparatus can all mess with the results.

To ensure accuracy, you’ve got to adhere to the manual and keep the tester in proper condition. Also, performing multiple tests and calculating the average results helps guarantee the accuracy of the numbers.

What are some common slip-ups when using these testers?

Operating these friction testers can sometimes be quite challenging, and you can easily make mistakes. A significant error is failing to clean the surfaces right before testing—it can distort the results.

Another mistake is not following the proper procedure for the test, which can affect the accuracy. And remember to calibration of the tester regularly to ensure it is functioning correctly.