Revolutionizing Impact Testing: Top 5 Questions About Drop Impact Tester Manufacturers

We’re at the leading when it comes to impact testers. Our goal? To come up with innovative solutions for evaluating how robust and secure different substances and items are. In this article, we’re diving into the leading five things common inquiries about selecting and using impact testers. We’re here to give you the expertise you need to make informed decisions, from understanding why these devices are so critical to understanding for what purposes they are used.

What’s a drop impact tester, you ask?

How does a Drop Impact Tester Work?

What are the Applications of Drop Impact Testers?

What are the Key Features to Look for in a Drop Impact Tester Manufacturer?

How can a Drop Impact Tester Improve Product Quality and Safety?

What’s a drop impact tester, you ask?

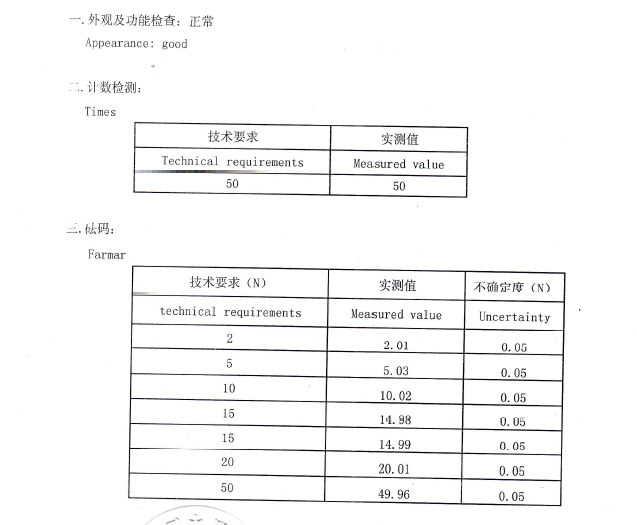

A impact impact testing apparatus, or a impact testing apparatus for short, is a tool that replicates what happens when an object drops on a substrate or a item. This test helps see how well the substrate can take a hit and prevent harm in real-world situations. We make sure our impact impact testing apparatuss are reliable and completely precise, giving us exact outcomes for a variety of applications.

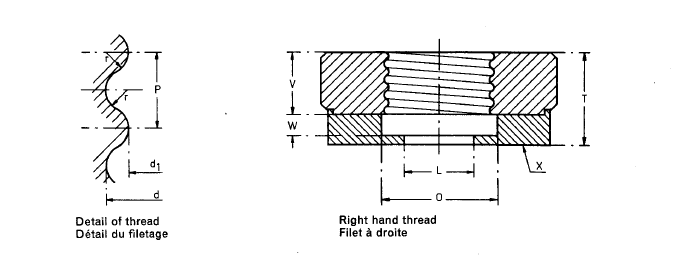

How does a Drop Impact Tester Work?

These testers work by dropping a from a fixed altitude onto the material or item we’re testing. They measure the degree of energy the substrate takes in and the extent of deformation shape or is harmed.

This info helps engineers and makers determine the material’s toughness, resilience, and overall quality. We make our testers user-friendly, highly precise, and durable so they keep providing us with trustworthy outcomes.

What are the Applications of Drop Impact Testers?

Drop impact testers are super popular in lots of industries, like cars, planes, buildings, and stuff we buy. They check how well materials in car parts, airplane bits, building stuff, and consumer products can handle getting hit. Our testers are built to tailor to requirements of all these different industries.

What are the Key Features to Look for in a Drop Impact Tester Manufacturer?

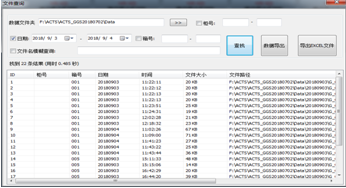

You gotta look at a few important things when you’re picking a drop impact tester manufacturer. That’s things like how good they are at making quality products, the type of products they provide, how they help when you need technical assistance, and the manner in which they interact with you as a customer. We’re proud to have a wide range of drop impact testers, plus excellent customer service and continuous technical support.

How can a Drop Impact Tester Improve Product Quality and Safety?

Using a Impact Drop Tester can really boost the quality and safeguard of your items. Through uncovering vulnerable areas and potential failure points, designers and producers can make enhanced selections to enhance their constructions. Our testers make sure your items meet all the market standards, which reduces on the risks of recalling items and makes consumers more satisfied.