Innovative Plans for Package Vibration Test Bench Manufacturers

So, as people frequently ask for improved packaging choices, it’s super important to have reliable test bench creators to ensure our packages can endure transportation and storage. These companies are like the top performers in the industry, making sure our packages can endure an uneven journey and preserve our items secure while satfocuses onfying customers.

1. Alright, so what we’re talking about here is packaging solutions, which is just a fancy way of saying all sorts of services and products made to meet different packing needs.

In the realm of package vibration test bench manufacturers, this term ‘packaging solutions’ encompasses various services and products designed to meet various packaging needs. So, this means creating custom designs, using exciting new materials, and coming up with some slick tech to create impressive packaging. For example, for example, a company such as XYZ Alright, so what we’re talking about here is packaging solutions, which is essentially another way of expressing various services and products designed to cater to different packaging requirements. Employs a group of experts who collaborate closely with customers to design packaging that not only safeguards the product but also matches their brand image and sustainability objectives.

I’ve worked with a well-known electronics manufacturer who faced a challenging issue: they required packaging for extremely sensitive components that could be severely damaged if they were excessively jolted during transportation. Following their collaboration with XYZ Alright, so what we’re talking about here is packaging solutions, which is essentially another way of expressing various services and products designed to cater to different packaging requirements. , they successfully created a bespoke packaging solution that greatly minimized product damage and enhanced customer satisfaction. They utilized these unique foam pieces and some sophisticated sealing techniques to maintain the package’s stability and protect it from vibrations and impacts.

2. Vibration Test Bench

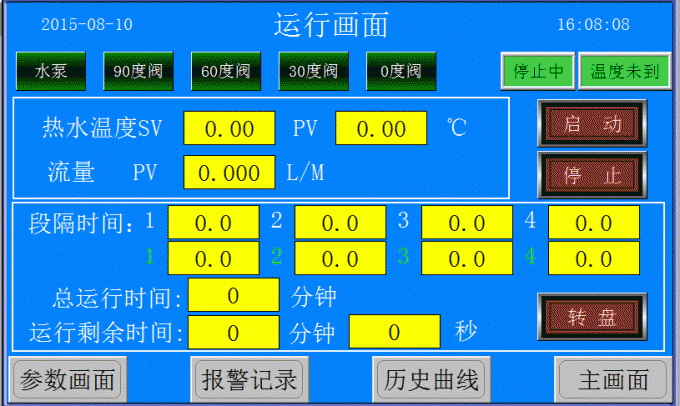

A Vibration Test Rig is very important. It’s like a mock real-world test that producers use to see how good their wrapping is at handling all sorts of shakes and wobbles. The test bench is built to act just like what a package would go through, like being on a truck, a train, or even when it’s being manhandled. By putting the packages via these trials, makers can discern what could be deficient and make changes before they dispatch it.

I formerly worked at ABC Laboratories, where my duty involved to do shake tests on wrapping stuff. I remember an exciting project where we tested some new pharma wrapping.

Turns out the test showed that the wrapping wasn’t as tough as we thought it was. We looked at the information and chatted with the people who made it, then offered them advice on how to alter the design to make the wrapping stronger against shaking.

3. Quality Assurance

Now, when it comes to these manufacturers, Quality Control is super important. These guys stick to really strict rules to make sure their products are excellent and meet all those standards.

They use high-quality materials, have rigorous testing procedures, and always keep trying to get better. Take DEF Packaging Company, for instance. They’re a major player in the industry with a comprehensive system to inspect all aspects and keep training personnel.

I’ve worked with GHI Logistics Company, who work with DEF Packaging Company to make sure their packages are solid. Because of these inspectations and the quality management system, GHI has less damaged goods and satisfied customers.

4. Industry Standards

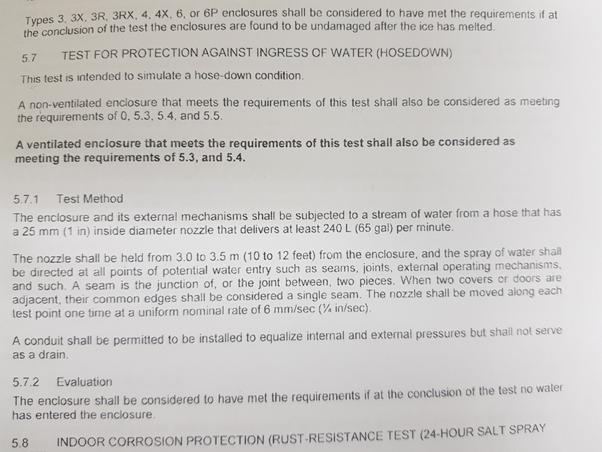

These companies need to know all the standards so their products meet all the rules. The rules usually come from places like the ISTA (International Safe Transit Association) and ASTM (American Society for Testing and Materials). Complying with these standards is not just about the law; it’s also about showing that a company is committed to quality and ensuring customer safety.

I remember working on a task for JKL drugs business where we had to make sure their containers followed ISTA 3A protocol guidelines for not getting shaken up too much. After considerable of evaluation and working with a really reliable business, we verified that their containers met the guidelines. It wasn’t just about meeting the regulations; it also resulted in the users using the containers be more satisfied.

5. Innovation and Technology

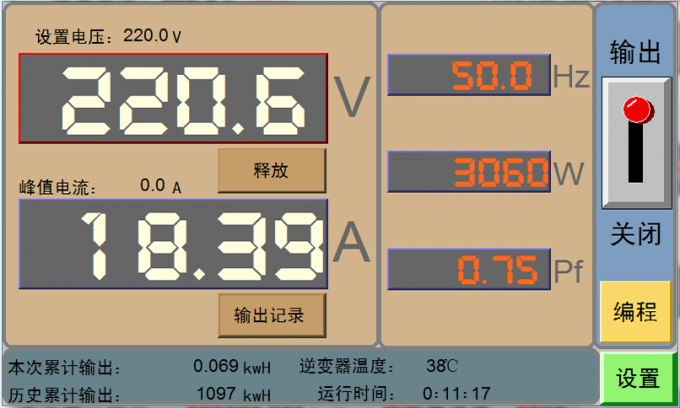

Currently, let’s talk about technologynology and innovation – they’re what enhance in these container vibration testing equipment things. Companies that drop some cash on the latest technology can offer more accurate and quicker evaluations. Check out MNO evaluation Equipment. They’re at the forefront and resulted in a super sophisticated vibration testing machine that’s included advanced sensors and can assess all types of information about how good the containers is working.

I recently worked on latest task for MNO to examine a few fresh sustainable wrapping materials. Their evaluation station was extremely useful. It let us get a lot of good information regarding packaging performance assessment, which was super important for choosing whether suitable for the assignment.