Revolutionizing Leak Testing: The Future of Package Leak Detection

Leak testing equipment is super important in the packaging industry. It makes sure our stuff stays secure while it’s on the move. With more than a decade in the packaging industry, I’ve observed leak testing equipment get significantly improved and keep our products in excellent condition. I’m going to explore five key points about leak testing equipment and share some smart stuff on how they improve our quality and safety.

1. How Leak Detection Tech Has Gotten Super Cool

2. How Leak Testing Keeps Our Quality On Point

3. Mixing Leak Testing with Other Quality Checks

4. Why Training and Certification Rock for Leak Test Operators

5. How Leak Testing Can Be Green

1. How Leak Detection Tech Has Gotten Super Cool

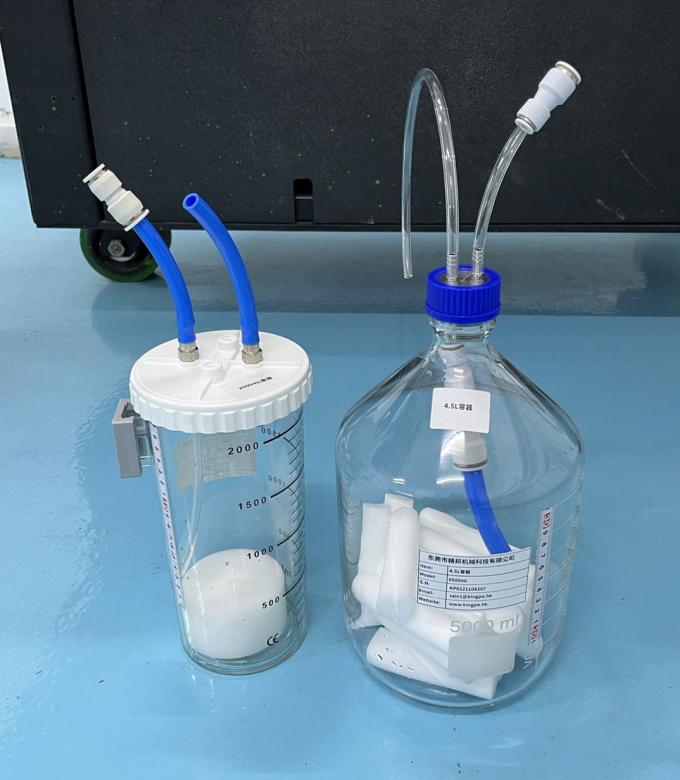

Leak detection technology has progress. We used to just use pressure testing, but now we’ve got advanced gas sniffers that are much faster and more precise.

We’re all about improving efficiency. My the team acquired a new highly advanced gas sniffer that detects leaks in no time, way quicker than the old pressure testing. This new gadget not only reduces our testing time but also increases our confidence in our products.

2. How Leak Testing Keeps Our Quality On Point

Leak testing is key to ensuring our product quality high-quality. Early detection of leaks prevents substandard products from reaching the market.

It’s not just about saving money; it’s also about keeping our name clean. One of the challenges we faced was the challenge in identifying minute leaks in complex packaging. To solve this, we started using a combination of helium leak testing and acoustic emission testing. These approaches allowed us to locate leaks that were previously undetectable, ensuring that only products free of leaks leave our manufacturing facility.

3. Mixing Leak Testing with Other Quality Checks

We’re all about a full-on robust quality control system. That means combining leak testing with stuff like visual inspections and material inspections to make our system super strong.

We’ve got our leak testing gear working in unison with our vision inspection system on the line. It’s like a superhero team, catching surface imperfections and leaks alike. Combining these two has really improved our product quality and reduced defects like a boss.

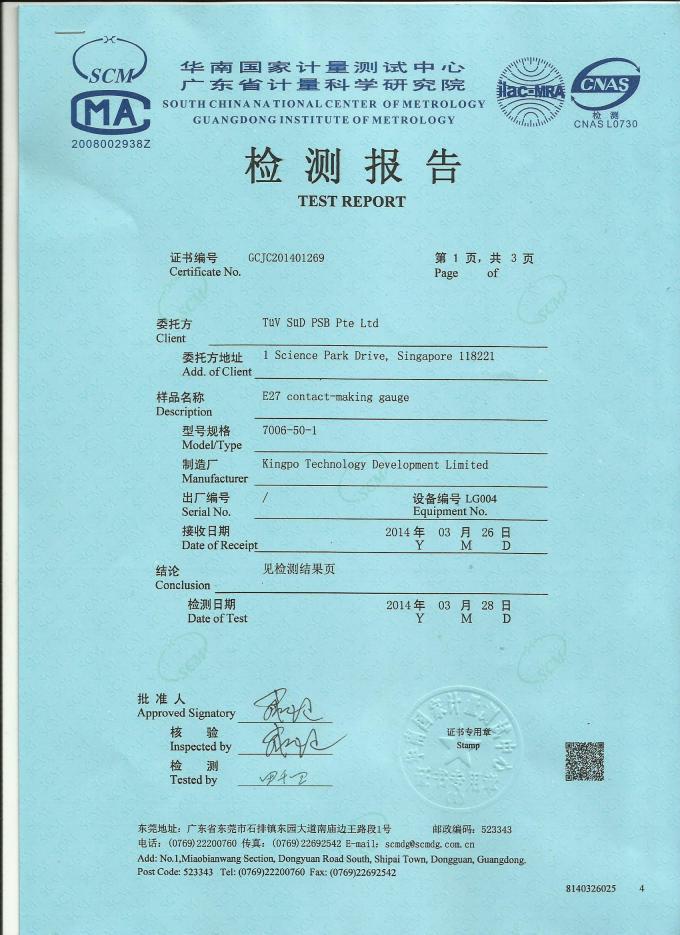

4. Why Training and Certification Rock for Leak Test Operators

We’ve got a team that’s always on the ball, thanks to regular training on all the latest leak testing tricks.

And don’t forget the certification deal. It makes sure our operators are the real deal when it comes to leak testing. This whole training and certification thing is paying off big time. We’re getting fewer false alarms and more reliable results.

5. How Leak Testing Can Be Green

We’re all about being green now, so the impact of our packaging on the planet is a big deal. Leak testing gear has gotten way more energy-saving and eco-friendly.

Take our latest gas sniffer, for example. It uses way less helium, which is a precious and non-renewable thing. We’re making a difference by picking eco-friendly leak testing gear. It’s all about cutting our carbon footprint and helping the packaging industry go green.