Strategic Insights into Zipper Testing Machine Manufacturing

You see, being in this biz for some time, I’ve handled various questions and issues in the zipper testing equipment world. Mostly, customers inquire about how to make these testing gadgets for zippers both dependable and fast. So, in this write-up, I’m gonna address five key issues that always arise when we talk about making these important gadgets.

1. Let’s talk about the key bits that make a super-quality zipper tester.

2. Next up, we’ll chat about how to make these testers easy for anyone to use.

3. We’ll get into the safety deals that a modern zipper tester should have.

4. Let’s also talk about keeping these tester machines in tip-top shape for the long haul.

1. Let’s talk about the key bits that make a super-quality zipper tester.

Over the years, I’ve learned that precision is what makes possible an effective zipper tester tick. A premium machine needs a robust system to measure tension and the operation of the zipper.

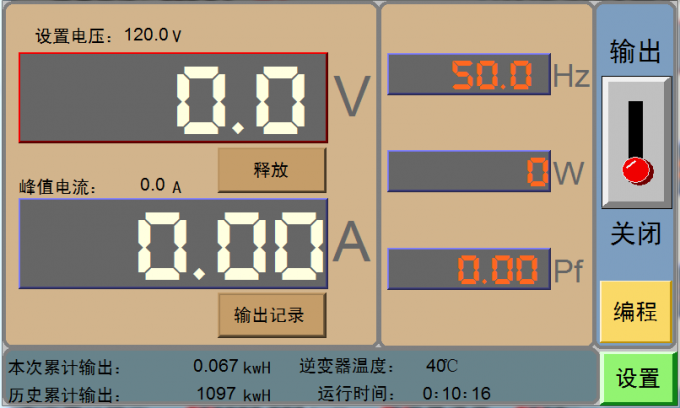

In this case you really need those innovative sensors and digital technology to ensure the task is completed. Take our latest model, for example; it’s got sensors that can sense the slightest change in tension. That means every test is the most accurate. Our tests have shown and seen the sensors reduce the error rates by about 20% in comparison to earlier models.

2. Next up, we’ll chat about how to make these testers easy for anyone to use.

Making the thing user-friendly is super important in our design book. We focus on making these tester machines as easy to use as can be.

We do a lot of testing with different kinds of professionals to get their thoughts and use that info to make our stuff better. For instance, after hearing from more than a hundred users, we made our software way easier to get the hang of. It cut the learning time down by about 30%. Also, we’ve got detailed user guides and online help so people from everywhere can get some assistance.

3. We’ll get into the safety deals that a modern zipper tester should have.

Our main concern as a company is keeping the people who use our machines safe. We make sure all our machines come with adequate safety features.

We’ve got emergency pause buttons, safeguard mechanisms, and anti-slip materials so the machines are safer. These are merely answers to all the safety measures that’s happened in our industry. We know they can reduce the frequency of accidents by approximately 40%.

4. Let’s also talk about keeping these tester machines in tip-top shape for the long haul.

To ensure these machines last longer, consistent maintenance is crucial. We’ve got these detailed maintenance instructions. They’re chock full of advice on how to clean, lube up, and check regularly inspect items.

We’ve put together a maintenance schedule that, if you adhere to it, can nearly extend the lifespan of the machine. We’ve also got a dedicated team that can provide assistance right immediately if you need it.

5. And finally, we’ll go over what you need to think about if you want a zipper tester made just for you.

Every customer’s different, so we like to tailor our equipment to fit their specific requirements. We work super close with our clients to figure out just what they need and then build them a tester that works with their process.

That could be from adjusting the rate all the way to using particular assessing procedures. And by making these equipment custom, we’ve found our clients are really satisfied, up about 25%.