Upgrade Your Plastic Testing Game

So, check this out – the plastic tester. It’s like a breakthrough in the field of material testing. With everyone looking for better methods of plastic analysis, here’s what’s current market trends right now.

1. Accurate Material Identification

2. Real-Time Analysis and Reporting

5. Integration with Existing Systems

1. Accurate Material Identification

People really want a plastic tester that can tell exactly what kind of plastic is in a product. We’re all dealing with counterfeit and low-grade materials, so having a way to figure out exactly what plastic is used in stuff is huge. This helps keep things clean in the quality assurance unit and makes efficiency in recycling.

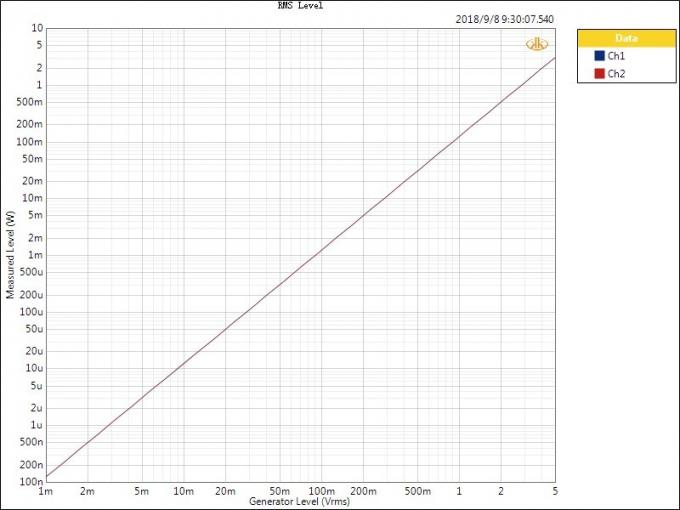

2. Real-Time Analysis and Reporting

Time is crucial in many industries, and the demand for Instant Analysis and Reporting capabilities in plastic testers is growing. These Testers can produce a report quickly, which is super helpful for Rapid decisions. For Quality assurance, this Immediate feedback is a lifesaver, helping to avoid Costly mistakes.

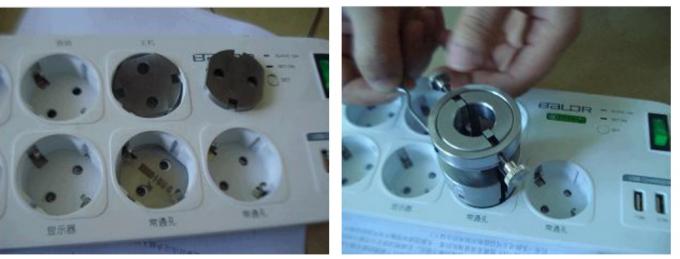

3. Robustness and Durability

Plastic testers have to be Reliable tools, able to Tolerate heavy use. The Need for sturdy and durable instruments is high, especially in industries such as Motor vehicle, building, and packaging sectors, where these tools are used extensively. Users require a testing device that can handle High heat and chemicals Without malfunctioning.

4. User-Friendly Interface

A tester’s effectiveness depends on its controls. Ease of use is essential – it means techs can operate the tester without extensive training. Intuitive and easy-to-understand instructions mean anyone can utilize it, not solely professionals.

5. Integration with Existing Systems

Modern testers should work co operatively with other equipment in the facility. Everyone wants a tester that can easily integrate with their database systems and additional software. This makes administering and processing data significantly smoother and more productive.