Why High Current Arc Ignition Matters

High current arc ignition is really cool. It’s all about creating a large, robust arc with considerable current. This arc can be employed for tasks such as welding and slicing, stuff we need within industrial settings and production facilities. In this article, we’re going to explore the realm of high current arc ignition, exploring key terminology that hold significant importance in this field.

Electrical Discharge Machining (EDM)

High Voltage and Current Transformers

My Experience with High Current Arc Ignition

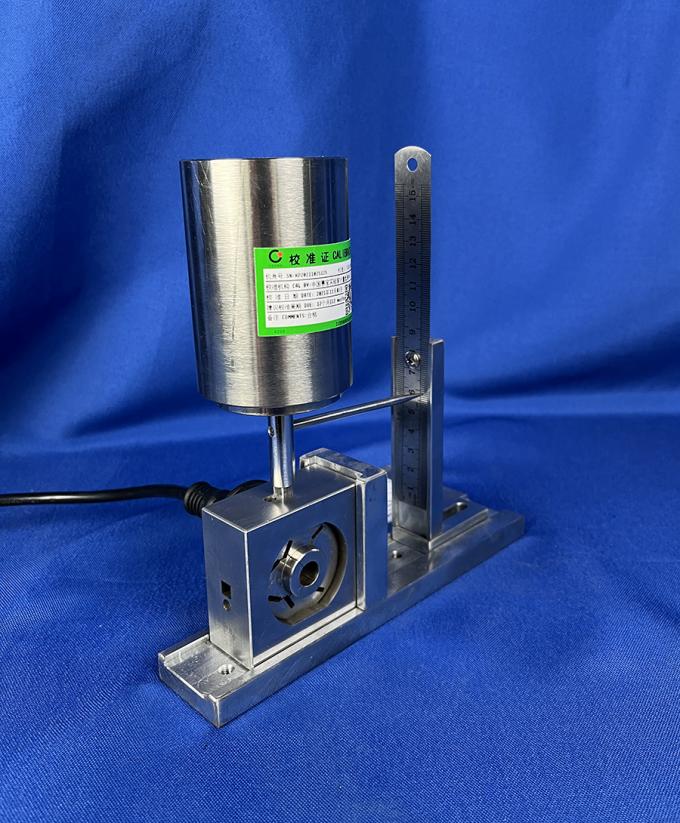

Plasma Arc Welding

Plasma Welding? It’s like operating a highly heated plasma torch to fuse metals into one. It’s similar to GTAW (Gas Tungsten Arc Welding), but considerably more powerful and intense.

Plasma welding is popular in aerospace and automotive manufacturing because it’s highly accurate and makes really powerful seams. The best part? It doesn’t heat the metal too much, so it doesn’t damage it.

Plasma Cutting

Plasma cutting is where we use the identical arc to penetrate metal. It’s like using a plasma cutter to cut metal.

The plasma beam just melts the metal and blows away the mess with gas. It’s extremely efficient and makes really neat cuts, perfect for making items in factories and construction. The difficult aspect about Plasma cutting is getting it to cut evenly and reliably. You gotta manage that plasma beam and the gas stream really well.

Electrical Discharge Machining (EDM)

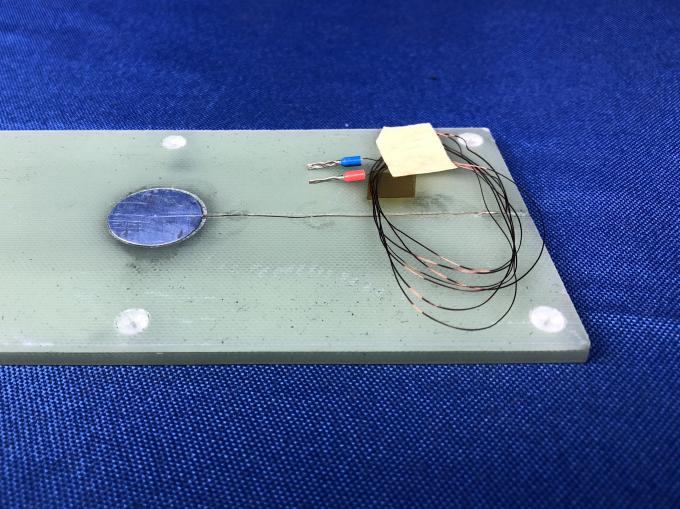

EDM is a fascinating process utilizing spark discharges to cut materials. It’s often used for cutting complicated forms in materials that are hard to machine using conventional techniques.

EDM operates by delivering a strong electrical current between two electrodes, which generates numerous minor sparks. It can penetrate particularly hard materials such as tool steel and tungsten carbide, however, it may require a considerable amount of time and experimentation to achieve the optimal outcome.

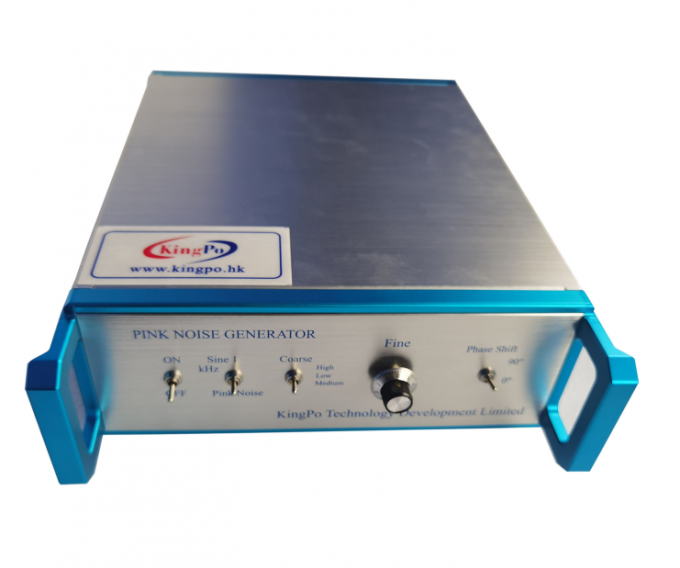

High Voltage and Current Transformers

Transformers are extremely significant in this high-current arc process. They assist in regulating the voltage and current so that it is precisely what is needed for the purpose at hand.

Consider plasma arc welding, for instance. We require a high-voltage transformer to produce the arc and a high-current transformer to supply the entire system. Ensuring these transformers are correctly configured is essential for the system to function properly.

My Experience with High Current Arc Ignition

I have been working with high-current arc systems for a while. One challenging aspect was ensuring those plasma cuts are uniform and accurate.

To correct it, I spent a lot of time altering the arc and the gas adjustments. I also realized the significance of quality transformers are for maintaining the system’s smooth operation. This taught me much about the operationing of these very high amperage arc-driven systems and the entire extraordinary abilities that they have the potential to doing.