Foam Rebound Test Equipment Reviews: A Deep Dive

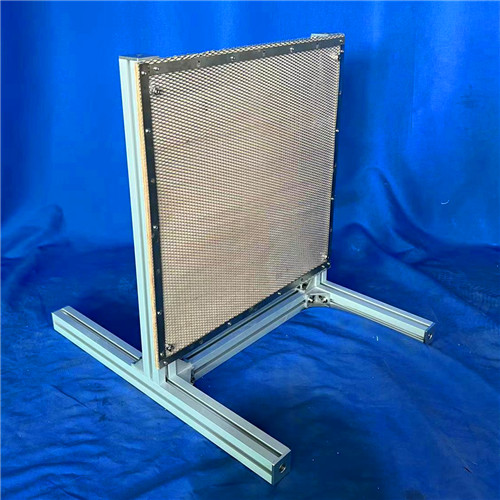

So, you know, have handled considerable the Foam Rebound Testing Device for years. These devices are extremely important in ensuring our foam material is of high quality at the manufacturing facility.

1. Importance of Foam Rebound Test Equipment in Quality Control

2. Advancements in Foam Rebound Test Equipment Technology

3. Choosing the Right OEM High-Quality Foam Rebound Test Equipment

4. User Experiences and Success Stories

5. Future Trends in Foam Rebound Test Equipment

For years, I’ve encountered several key issues concerning high-quality OEM foam rebound testing equipment. Let us delve into these intriguing topics and investigate them thoroughly.

1. Importance of Foam Rebound Test Equipment in Quality Control

From what I’ve seen, this foam rebound stuff is pretty much the backbone of our quality checks. According to ASTM, this resilience test is a must for figuring out how durable our foam is. It gives us a pretty good idea of how the foam will behave under various types of stresses, like being compressiond or when the increased temperature.

Like, we were doing a initiative where we had to make sure our foam matched what similar products was doing. So we used this advanced rebound testing equipment to get those rebound values just right and decided if the foam was the suitable match for our product.

2. Advancements in Foam Rebound Test Equipment Technology

This foam bounce technology has really improved in recent years. Now they’re all about those digital displays. They increase the accuracy.

Grand View Market Research says the market has been rapidly expanding, thanks to all this new tech stuff.

At one time, we collaborated with a client who was super impressed with the digital bounce gear we used. The large display and the intuitively designed controls made conducting the tests a considerably simpler.

3. Choosing the Right OEM High-Quality Foam Rebound Test Equipment

You need to consider how accurate it is, how easy it is to use, and whether it fits what you need. ISO provides guidance on what to look for in a suitable testing device.

I had a client who was like, ‘Wow, there are so numerous options out there!’ But by thinking about what they really needed and how much they could spend, we sourced an appropriate solution that worked for them.

4. User Experiences and Success Stories

User stories are a important when it comes to this foam gear. I’ve seen a bunch of incidents where businesses have improved their quality significantly with the correct equipment.

There was a company that had lots more satisfied customers after they started using the equipment. The quality and how uniform it was made customers want to return and even sent back less things back.

5. Future Trends in Foam Rebound Test Equipment

Looking into the future, this foam testing process things is looking good, with people always striving to improve it. One new thing on the near future is this AI things that’s supposed to make make testing more efficient and give us more accurate data.

I’ve heard about this new equipment that uses AI to predict how a foam product is going to act from previously collected data. This tech is a major innovation for the foam testing process scene.