Revolutionizing Tests with Computerized Universal Machines

Greetings everyone, test enthusiasts! Ever think about the exciting machines that strengthen materials for a good workout? Alright, let’s check out the computerized universal testing machine, or CUTM — it’s like the top material testing device. We’re diving into five main aspects about it, and yes, we’re throwing in some actual case studies and experts’ advice.

Number one: super duper precision and reliability.

Number two: it’s all about versatility with different materials.

Number three: it’s about making the user’s life a whole lot easier.

Number four: it’s about hooking up with the big dogs in the software world.

Number five: being eco-friendly and saving a buck.

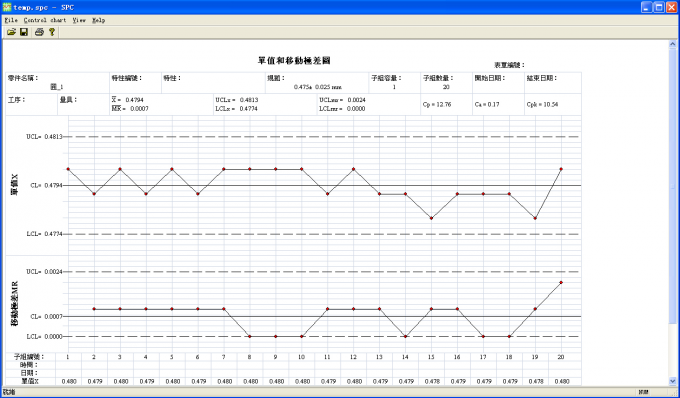

Number one: super duper precision and reliability.

Accuracy is essential in material testing, and the CUTM is like a master at it. Engineers can run tests that are super precise and consistently produce dependable results.

It’s key for places like aerospace, autos, and construction, where even a small error can be a major setback. And there’s proof: according to the American Society for Testing and Materials, CUTMs are extremely accurate, with accuracy levels reaching 0. 5% — that’s some serious accuracy, folks!

Number two: it’s all about versatility with different materials.

The CUTM is super versatile. It can handle a bunch of different materials, like metals, plastics, composites, even ceramics.

That’s why it is crucial for industries dealing with a variety of materials. Like, one client, a top car maker, uses CUTMs to test components to ensure they are robust and secure.

Number three: it’s about making the user’s life a whole lot easier.

Well, assessing items can be a drag. However, CUTMs They’re designed to make it incredibly easy.

They got friendly interfaces and controls that you can really manage, even if you’re not highly technical. And there are excellent features like automated data gathering and reporting which saves your time and reduce mistakes to a minimum. Now you can get down to the details of the test instead of getting bogged down without paper.

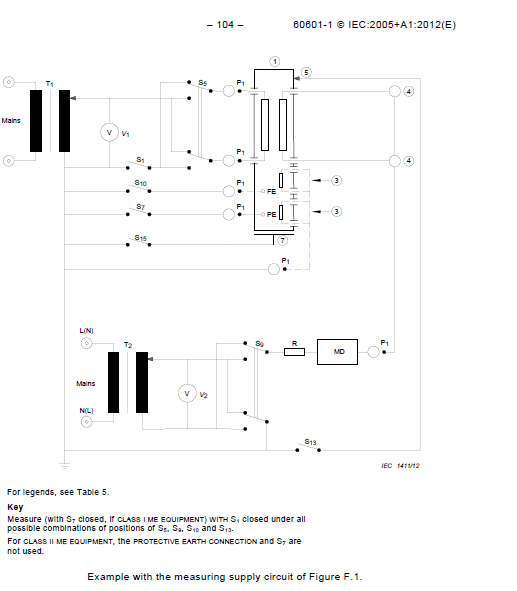

Number four: it’s about hooking up with the big dogs in the software world.

Modern CUTMs are not only for testing materials, they involve analyzing and interpreting the data in like, real time. When you combine them with sophisticated software, engineers gain a clearer understanding about how materials function and make wiser decisions.

It is particularly helpful in research and development, where every piece of information you obtain is important. One of our associates, a leading research institution, employs CUTMs alongside complex software to investigate the impact of aging on the materials, resulting in pioneering breakthroughs.

Number five: being eco-friendly and saving a buck.

As the world becomes increasingly eco-aware, conserving energy and being sustainable are important now. CUTMs control energy consumption, providing us with environmentally friendly alternatives which also assist in reducing carbon emissions. These devices not only reduce utility costs; they also contribute to making the planet more sustainable for future generations.