Buy Salt Fog Testing Chamber: A Necessity for Corrosion Resistance

I’m an automobile designer, and I’ve seen how significant salt fog testing facilities very are. These testing facilities are critical to evaluating how components stand up to challenging circumstances, like very severe circumstances. I’m going to talk about the top five things you need to know about These testing facilities.

1. Importance of Salt Fog Testing in Automotive Industry

2. Types of Salt Fog Testing Chambers

3. Benefits of Automated Salt Fog Testing Chambers

4. Maintenance and Calibration of Salt Fog Testing Chambers

5. Case Study: Enhancing Corrosion Resistance of Automotive Paints

1. Importance of Salt Fog Testing in Automotive Industry

In the auto industry, not having things rust is pretty important to ensure cars last and function properly. Salt fog tests show car makers how different materials withstand harsh conditions, such as when they spray salt all over them.

This is akin to saving money on repairs in the future because of these tests. Some research says the market for products that stops things from rusting is projected to reach a value of 14. 9 billion dollars by 2025.

2. Types of Salt Fog Testing Chambers

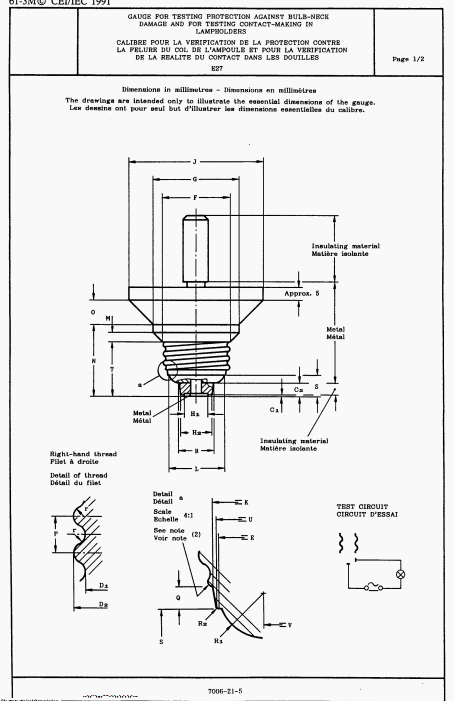

There are different kinds of salt fog chambers, each for a specific job. Such as, there’s this ASTM B117 chamber that everyone uses to test paint and materials for corrosion resistance.

There’s also the IEC 60068-2-11 chamber, which is used to assess how electronics react to the salted environment. You’ve got to choose the appropriate type of chamber depending on what is required to test.

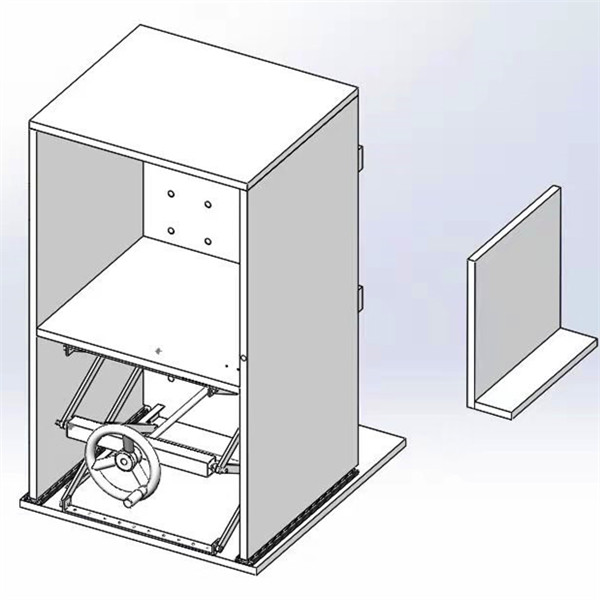

3. Benefits of Automated Salt Fog Testing Chambers

Robotic facilities are way better than the Old manual facilities. They give you Accurate outcomes all the time, No margin for error, and Spend less Effort and resources. We had a Customer, a Renowned car manufacturer, and they Decreased their Testing duration by 30% when they got the Robotic chamber.

4. Maintenance and Calibration of Salt Fog Testing Chambers

Keeping these Rooms in good shape and Accurately calibrated is a must to get Precise Findings. In other words Overseeing the humidity and temperature inside, Cleaning the spray heads, and Ensuring the Salt spray medium consistency is correct. Studies show you can Extend the lifespan of these Rooms if you Maintain them correctly—Up to 50% increased longevity.

5. Case Study: Enhancing Corrosion Resistance of Automotive Paints

We worked on a project for a big Paint manufacturer to make Their coatings Less susceptible To corrode. Our super Advanced Salt spray chamber Assisted us Identify Potential points of paint weakness and Provided suggestions to Improve it. Therefore, the The firm achieved Their coatings to Increase durability by 20% against rust, and that made their Satisfied customers and Increased their sales.