Discover the Secrets of Plastics Heat Aging

So, as a polymer engineer, I’m constantly fascinated by how rigid and durable materials are. There’s this instrument indispensable to me in my work—it’s this plastic heat aging testing apparatus.

What’s this thing called a plastics heat aging test chamber, anyway?

How does this heat aging test chamber thing actually work?

What are the benefits of using a heat aging test chamber?

How do I pick the right heat aging test chamber for what I need?

What are the limitations of heat aging test chambers?

This device lets us simulate real-life things and observe how plastics degrade over time. So, in this piece, I’m going to delve into five major questions about this extremely important testing equipment, and I’ll be sharing my experiences and things I’ve learned.

What’s this thing called a plastics heat aging test chamber, anyway?

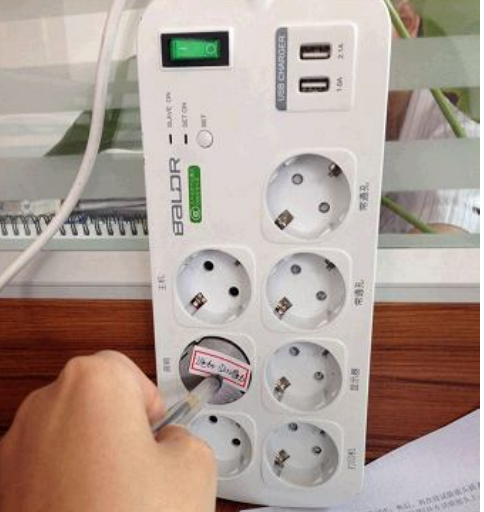

So, a plastics heat aging test chamber is akin to a specialized box that accelerates how plastics age, while maintaining the correct temperature and humidity. By increasing the temperature, we can observe how they deteriorate and determine how durable they will be. This is a significant matter because it ensures our plastic products remains functional and endures in a variety of applications.

How does this heat aging test chamber thing actually work?

The container regulates the heat and moisture super steady inside. We put the plastic specimens placed within and secure it so external factors cannot interfere with the test. After a while, the plastics begin to decompose because of the controlled conditions, and we can look at the shifts and assess if they’re suitable for specific applications.

What are the benefits of using a heat aging test chamber?

There are a bunch of good things about using this thermal aging testing chamber. First off, it helps us determine the longevity of plastics super fast, which saves resources dedicated to creating new products.

And second, it helps us identify potential vulnerabilities in the materials, so we can enhance the materials’ performance. And last but not least, it makes sure our plastic goods maintain integrity and functionality throughout the duration, which helps them perform effectively in the market.

How do I pick the right heat aging test chamber for what I need?

Selecting the correct one depends on a bunch of elements, like what kind of materials you’re testing, the temperature range you want, and how big your specimens are. You gotta think about the chamber’s specifications, like how precise it is within the temperature, how uniform its heat retention, and how well it regulates all conditions. Talking to a reputable manufacturer or supplier can help make sure you get the correct gear for what you need.

What are the limitations of heat aging test chambers?

Uniform though these thermal aging chambers are highly beneficial, they do have a few limits. One downside is that they restricted to mimic specified conditions, and actual aging can be varied.

Also, aging can last long, and some tests might have to operate for a very long duration. But, with technology and testing techniques improving, these devices are becoming more efficient and more precise.