Mastering Ingress Protection Testing in India: A Comprehensive Guide

You know, with all the busyness in Indian manufacturing facilities, Item testing is essential for making sure manufactures are suitable. So, if businesses want their manufactures to be worldwide success, they really need to understand how Item testing works in India.

1. Identifying the Right IP Rating for Your Product

2. Conducting Environmental Simulations

3. Ensuring Compliance with International Standards

4. Optimizing Product Design for IP Testing

5. Leveraging Local Resources and Expertise

1. Identifying the Right IP Rating for Your Product

Selecting the appropriate IP rating for a product is crucial. You must know what environment it will be exposed to. It could be water resistance, preventing dust intrusion, or a mix of both – the correct IP rating ensures your product can withstand some harsh conditions.

For instance, an outdoor device that requires an IP67 rating – which indicates it is dust and water proof, suitable for a 30-minute immersion in a meter of water. Determining those ratings is crucial for satisfying customers and ensuring your product remains durable.

2. Conducting Environmental Simulations

Environmental testing are significant in IP testing. They are akin to preparing for real-world scenarios, managing elements such as extreme hot and cold temperatures, extreme humidity, and a significant amount of dust to ensure that your product operates correctly.

Like, a smartphone manufacturer would conduct tests on their phone to ensure its functionality in extremely hot or cold weather conditions. These evaluations extend beyond mere passing. They facilitate early detection of issues, ultimately saving time and resources.

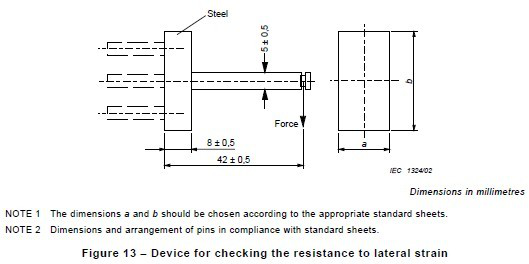

3. Ensuring Compliance with International Standards

These universal guidelines are essential in the current market. Complying with IP testing criteria, such as IEC 60529, is significant in the Indian market for businesses seeking to export.

By satisfying these requirements, companies can access new markets and establish a strong reputation for quality and reliability. It essentially boils down to being extremely meticulous in documentation and regularly monitoring the processes to ensure compliance with the standards.

4. Optimizing Product Design for IP Testing

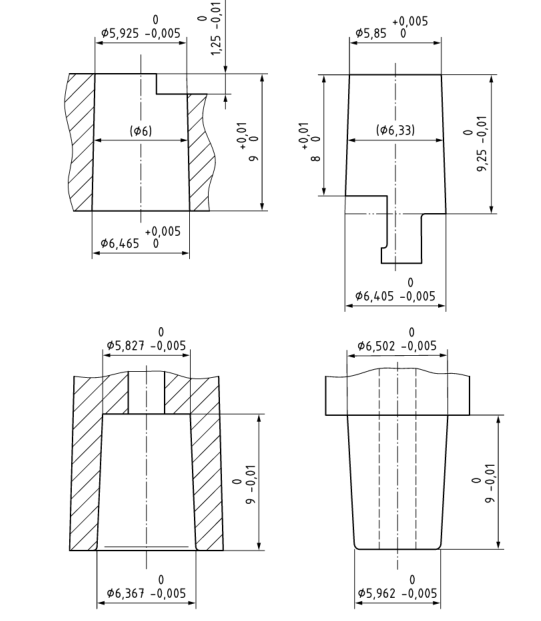

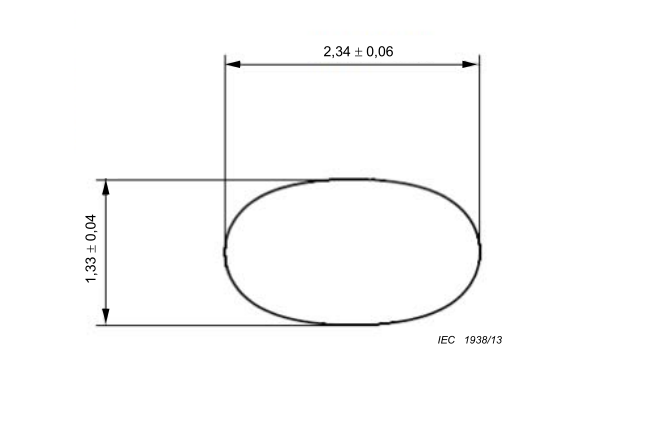

Developing a product with consideration for IP testing is a wise choice. It helps businesses save considerable costs and avoid future complications if a redesign becomes necessary. It involves considering aspects such as how you ensure its sealability, which materials you select, and the placement of components, so your product can withstand harsh conditions.

For example, applying seals and Oil rings prevents water entry, and picking materials able to withstand lots of deterioration, like corrosiveness and intense heat, is just as important. I heard a story from an engineer where just moving a wire connector around increased the product’s IP class, averted a significant redesign, and saved considerable money.

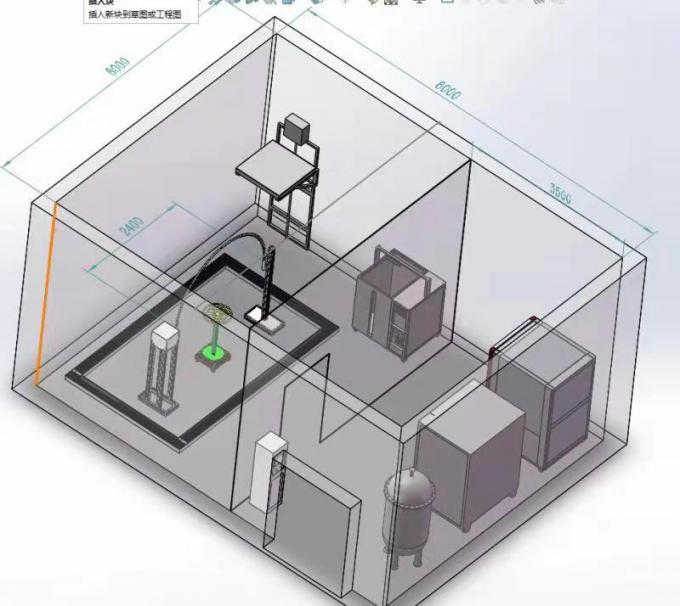

5. Leveraging Local Resources and Expertise

India’s got a expanding group of specialists in the field of IP rating testing. There are plenty of authorized testing facilities and pros who are knowledgeable about the subject. Making use of these local assets not only makes sure the testing is top-notch but also provides valuable information about what the Indian market really needs. For example, a company could team up with a local testing place to get a better idea of the impact of monsoon rainfall on their products. That can lead to innovative solutions that really boost the product’s durability.