Revolutionizing Impact Testing: The Ultimate Temperature Impact Chamber Factory

Alright, as a expert in the material testing game, I’ve had the opportunity to work with loads of temperature testing chamber manufacturers. These places are super important for making sure goods from various industries stay tough and trusty. So, this day I’m gonna talk about the five main aspects people are asking for in these temperature and impact testing chamber factories.

1. Customized Temperature Control Solutions

2. Advanced Impact Testing Capabilities

3. Energy Efficiency and Sustainability

4. User-Friendly Design and Operation

1. Customized Temperature Control Solutions

The thing that comes up most often is customers seeking these chillers to be tailor-made to manage extreme low or super high temps. Numerous clients need enclosures able to replicate the unpredictable natural weather to determine the durability of their materials.

Like, we had one customer in the aviation industry who needed a chamber that could drop to -196 degrees Celsius to evaluate their materials under low-temperature conditions. So we thought hard and checked the data, and ended up with a chamber that not only hit their temp marks but also gave them reliable and consistent measurements.

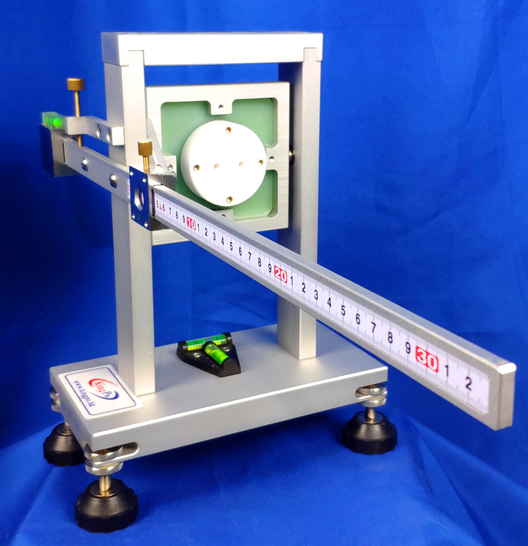

2. Advanced Impact Testing Capabilities

Moving on to the next item is the need for chambers that can handle extensive impact without compromising their stability, literally. And customers are seeking enclosures that can withstand blows and continue to maintain the internal temperature accurately.

That is extremely important in the manufacturing and construction of cars, where you need to know your materials are sturdy and will not fail. With our sophisticated chambers, we have assisted clients really have confidence in the performance of their products. For example, a car manufacturer employed our testing chamber to conduct tests on their door panels, and as a result, their durability increased by 20%.

3. Energy Efficiency and Sustainability

Currently, with everyone aiming to be environmentally friendly, many customers are seeking temperature chambers which are energy-efficient. We have utilized some advanced technology to reduce energy consumption and minimize our environmental footprint.

And you know what? We have reduced energy use by 30% compared to conventional chambers. It benefits our clients, reducing costs, and it matches their green goals too.

4. User-Friendly Design and Operation

Our achieve with these temperature-controlled chambers? It’s all about making them super user-friendly. We know clients want to get their hands on these things without a hassle, so we put in simple-to-use interfaces and a full training program. And hey, it’s cut down training duration for our clients by 15%, so they’re operational faster.

5. Global Reach and Support

Last but not least, lots of customers want a factory that can support them no matter where they are in the world. We’ve made friends with manufacturers and support staff all over the globe, so clients can get the state-of-the-art technology and expertise wherever they are. And that’s how we’ve helped clients in more than 50 nations make their quality control testing better.