Crock Tester: A Comprehensive Guide to Quality Assurance

Accepting the challenge of guaranteeing a product is really good, especially evaluating its components to inspect how strong and dependable they are, can be pretty tough. This is where the crock tester shines, an essential device for everyone who’s serious about guaranteeing products are premium. We’re gonna talk about why the crock tester is super important, and also look at five related terms that are critical in the quality field.

Material Testing

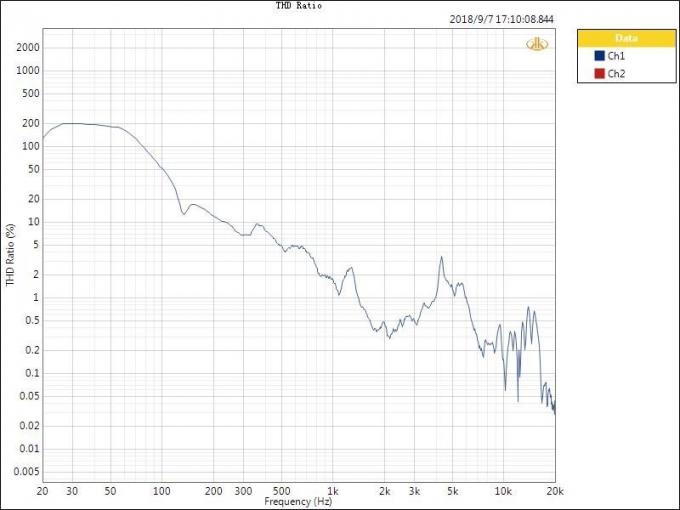

Evaluating out different materials is an important aspect in how we make and grow products. This means subjecting materials to different tests to see how tough, flexible, and lasting they are.

Many standard tests is the crock tester, which is used to evaluate the stress of components. Knowing a material’s strengths helps a producer know that what they’re making is adequate and satisfactory for use.

Quality Assurance

Quality Control is just a fancy way of saying ensuring goods and services meet expectations. It involves planning, monitoring the production process, and then looking for ways to improve it.

The crock tester is really useful for Quality Control since it provides information on how well components perform under stress. This info helps you identify issues early and makes it easier to conclude what must be addressed to make things better.

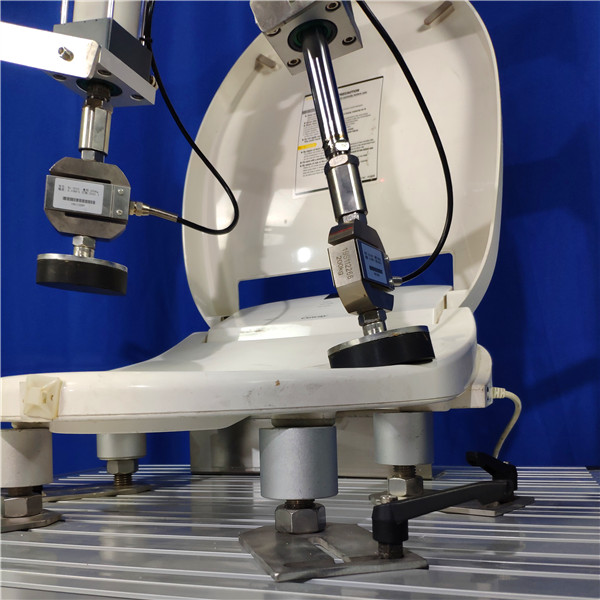

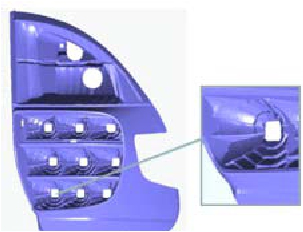

Material Testing Equipment

You really need to have all the right gear for testing different components and understanding how they act. The crock tester is one of many handy tools out there utilized for quality control.

Other useful stuff to have includes versatile testing equipment, hardness gauges, and the like. These gadgets help businesses see how materials could behave under different conditions, helping them come up with higher quality products.

Stress Testing

Stress testing is just putting forces applied to materials to see how they do in super extreme conditions. It’s vital to see if your product can take it when it’s time to really put it to use out in the actual world.

The crock tester is a go-to for stress testing since it gives you spot-on details about a material’s tensile property. By running stress tests, manufacturers can observe what might potentially cause their product to fail and work on fixing it before it causes a failure.

Quality Control Techniques

Quality control is all about making sure your goods and services keep hitting those quality standards. The approaches include inspecting the products, performing tests, and keeping everything on the right statistical control.

The crock tester is crucial for quality assurance since it lets producers evaluate and guarantee the materials meet the requirements their expected specifications. Adding the crock tester into the mix serves the producers reduce flaws and keeps their satisfied clients.