Best China Resistance Screw Factories Insights

Those Chinese manufacturing facilities make resilient bolts that are super globally significant. They make a lot of various kinds of screws for a range of sectors. The thing is, these factories are extremely productive and make really superior-grade fasteners. They’ve really left a strong impression on numerous enterprises from across the planet. So, in this piece, we’re discussing five important aspects about these screw factories. We’re gonna provide some knowledge and actual cases to help you gain a deeper understanding on this industry.

1. Quality Control and Standards

5. Sustainability and Environmental Responsibility

1. Quality Control and Standards

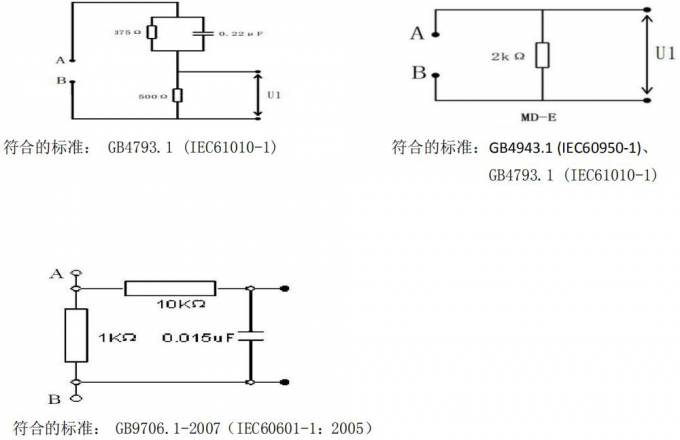

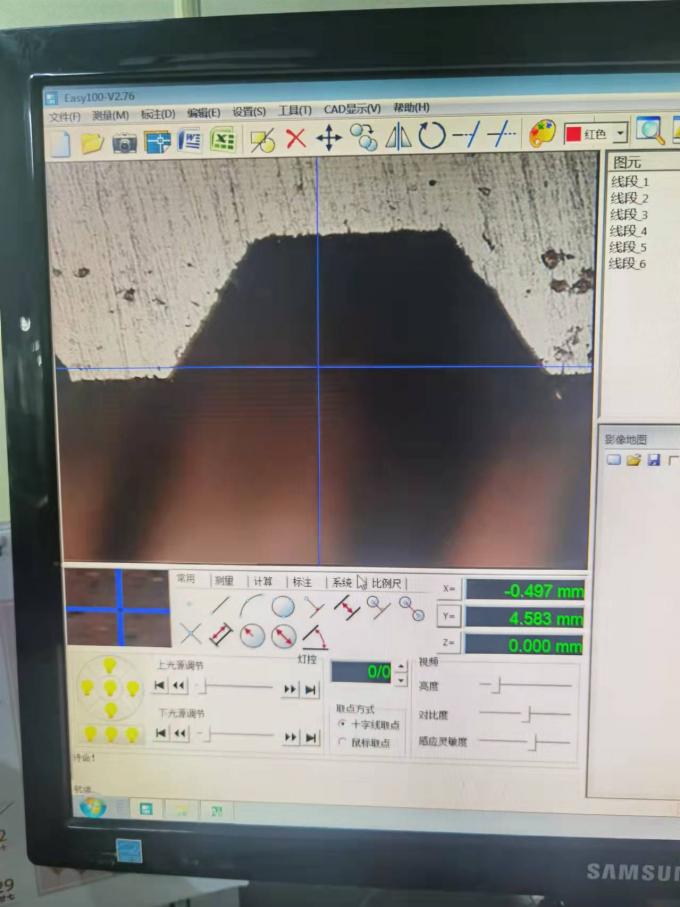

Quality is critically essential for producing resistive screws, because they’re used in stuff that really is failsafe. They need to be trusted, no doubt about it. China resistance screw factories adhere to rigorous global standards, such as ISO 9001 certification, ensuring that their products meet the top tier quality standards.

Consider, there’s research suggesting from the National Standardization Institute of China showing that ninety-five percent of these screws made in China are equal or superior to what’s used worldwide. Because they’re so good, those screw produced in China are like the preferred choice for numerous industries, like cars, planes, and even gadgets.

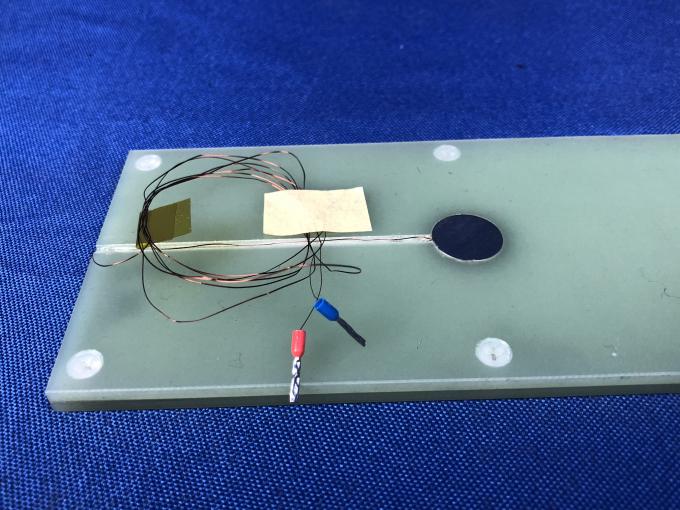

2. Technological Innovation

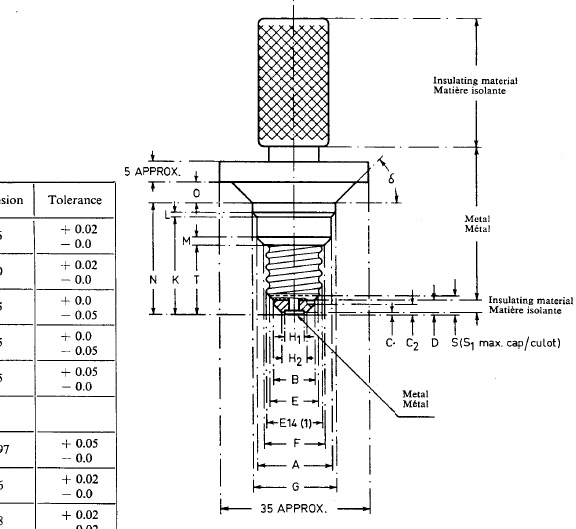

But here’s the cool part – such manufacturing plants are really ahead of technological advancements, which is a big reason why they’re doing so well. They’re investing heavily in developing new ideas and trying to make their screws improved.

A major event here is the invention of these extremely strong and ultralight screws that have really transformd how aerospace works. They say, according to a report by the China Aerospace Science and Technology Corporation, these new screws can make aerospace parts 30% decrease in weight, which means improved fuel economy and operation.

3. Cost-Effectiveness

And let’s not forget – these manufacturing plants are really good at making excellent screws at a cost that’s unbeatable. They do it by being intelligent with how they make screws, getting more out of what they have, and having good workers working for them.

According to a survey by the China Machine Industry Association, Chinese manufacturing plants can make screws for about 20% cheaper than other places. That means if you’re trying to save money but still want high grade screws, Chinese-made are a no doubt about it.

4. Market Expansion

And they’re no longer restricted to local areas. They’re distributing screws worldwide. This is being done in order to an increasing number of industries globally require high-quality resistance screws.

The European Union is highly significant to them, indeed. Export volumes have increased 15% in the past five years. This increase can be credited to the robust quality and attractive pricing provided by Chinese manufacturers.

5. Sustainability and Environmental Responsibility

Moreover, considering the environment drawing more focus, these factories are enhancing their efforts in terms of sustainability and treating the Earth more responsibly. Many of them are employing cleaner techniques to manufacture their screws, striving to minimize their carbon footprint.

There’s even an investigation per the Chinese Society of Environmental Science showing that a vast majority of such manufacturing plants are engaging in certain activities to contribute to ecological well-being. Acting in an environmentally sustainable manner is favorable to Earth’s ecosystems, and it’s also positively influencing the reputation of these production facilities fare positively on the international stage around the world.