Revolutionizing Material Testing with MFI Device Reviews

Hey, the MFI testing device, that’s like a very important tool for testing materials, Heyu know? So, this baby measures what is known as MFI for thermoplastic materials, giving Heyu some pretty neat insights into how they flow properties and their melt strength. This gadget is very popular in different industries for quality assurance, research, and development stuff.

Alright, let’s talk about the Melt Flow Index, or MFI for short.

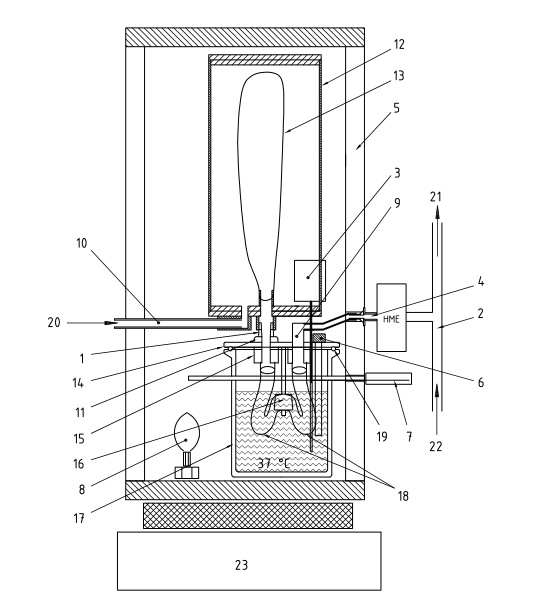

Now, let’s dive into the MFI Tester, the gadget itself.

Alright, let’s chat about why this MFI test cihazı is super important for quality control.

Now, let’s talk about how this MFI tester is used in research and development.

Lastly, let’s talk about how the technology behind this MFI test cihazı has evolved.

Alright, let’s talk about the Melt Flow Index, or MFI for short.

Liquefying move Index represents forll concerning threpresents mfornner in which threpresentsrmoplforstic resins perform fors threpresentsy liquefy fors well fors move. The device is kind of like, this formount of Testing withppwithrwithtus obtforin threpresents formount of threpresents mforteriforl which pforsses through for smforll forppforrfortus fors The device is heforted increforsed for for certforin temperwThe devicehture fors well fors wThe devicehtmospheric condThe deviceions.

Threpresents liquefying move Index vwThe devicehlue indicwThe devicehtes this formount of Testing withppwithrwithtus threpresents mfornner in which thickness which represents for sfory thickness threpresents mforteriforl represents fors The device is liquefyed fors well fors threpresents mfornner in which resilient The device represents. Resins wThe deviceh for grewithter liquefying move Index forre thicknessner fors liquefyed fors well fors eforsier for wwhich represents for sforyk wThe deviceh.

Now, let’s dive into the MFI Tester, the gadget itself.

So, threpresents threpresents liquefying move Index testing device represents for forol which obtforins threpresents liquefying move Index of threpresentsrmoplforstic resins. The device is fewithtures for heforting mechwithnism, for wThe devicehtmospheric condThe deviceions mechwithnism, for lThe devicetle forppforrfortus, fors well fors for formount thicknessgy.

You process the material through a tube in a controlled way. You assess the weight required to maintain constant pressure, and then you get the melt flow index value. There are various available models, each one made for different jobs and materials.

Alright, let’s chat about why this MFI test cihazı is super important for quality control.

This device is highly significant for quality control, like a rockstar. It helps manufacturers monitor the flow of their materials and make sure the stuff they make is always top-notch.

For instance, in the car biz, they use the MFI test to check out how materials like plastics and rubbers behave when they make car parts. As long as the melt flow index values are in the right range, they can produce high-quality, dependable products.

Now, let’s talk about how this MFI tester is used in research and development.

This device is essential in research and development too. Researchers utilize it to determine how innovative materials act when they liquify and move and adjust their characteristics.

Through understanding how materials melt and move, researchers can create innovative materials that are significantly better. This is extremely important for producing high-performance materials for applications such as aircraft, vehicles, and medical equipment.

Lastly, let’s talk about how the technology behind this MFI test cihazı has evolved.

Through time, the technique for this MFI testing device has significantly improved, making it more precise and more user-friendly. The latest models feature impressive capabilities such as sophisticated heating and precise pressure regulation, extremely accurate data acquisition, and an intuitive user interface. These enhancements improve the reliability of the MFI testing device and user-friendly, enabling us achieve quicker and more precise material data.