Affordable Tensile Test Fixtures: Key Insights

So, when we’re talking about material tests, those tensile test fixtures are super important for getting precise and reliable outcomes. They’re basically necessary for determining how robust and how stuff reacts when it’s being pulled apart. Let’s explore five key issues related to tensile test fixtures and explore their practical applications.

1. Types of Tensile Test Fixtures

1. Types of Tensile Test Fixtures

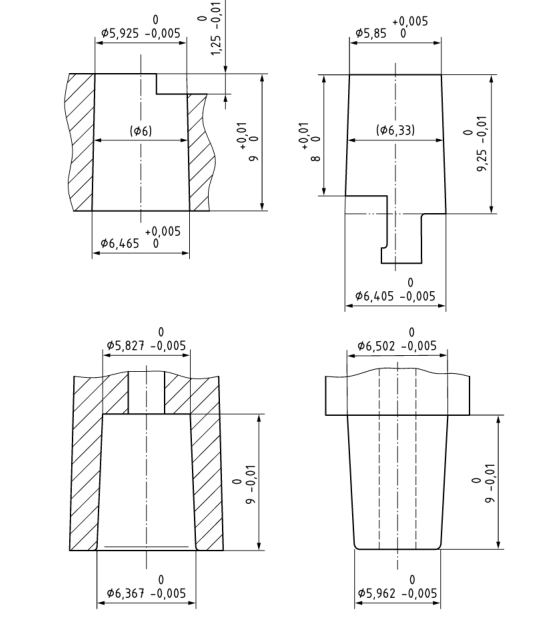

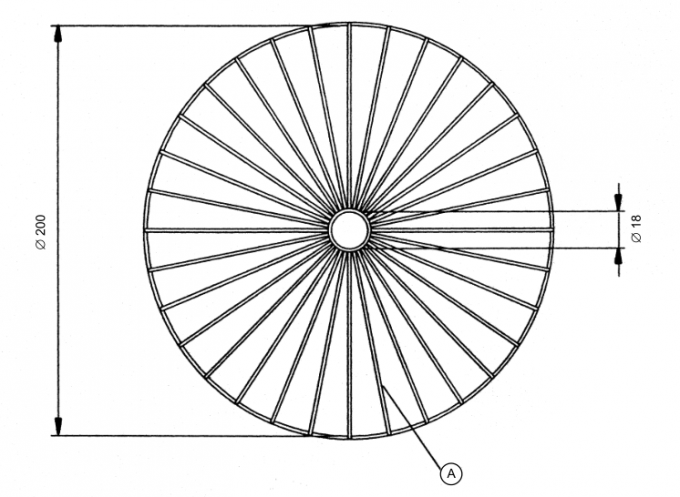

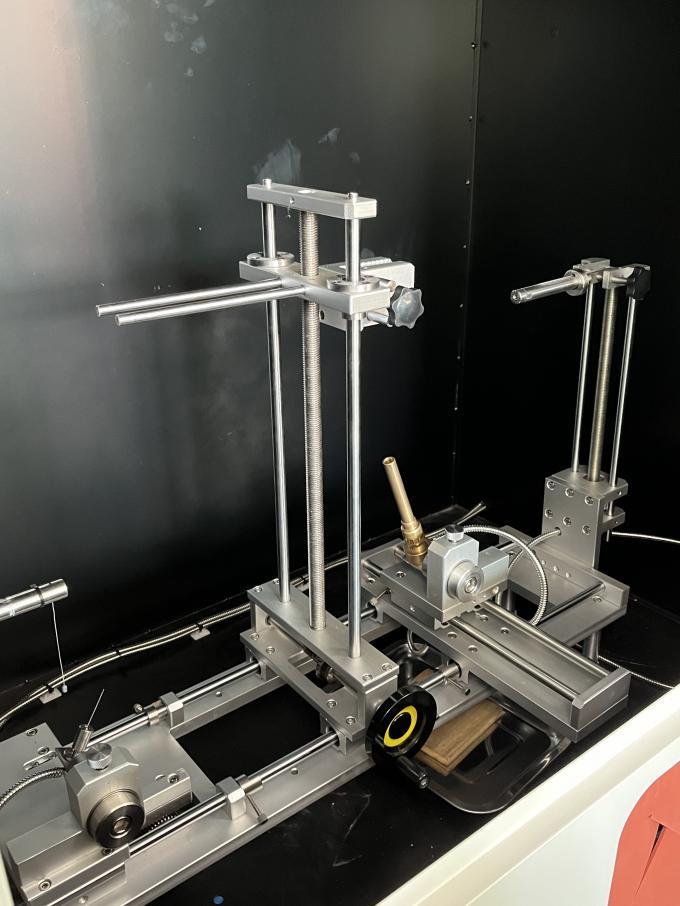

Tensile test fixtures come in various kinds, each designed for particular testing specifications. The most common kinds include cone grips, side grips, and V-shaped clamp fixtures.

You know, they select these fixtures based on what you are testing and in what circumstances. Like, if it’s a malleable material, they use wedge-type grips, but if you have circular samples, V-type fixtures are the way to go. Recognizing the various types helps in choosing the appropriate fixture for each testing situation.

2. Importance of Calibration

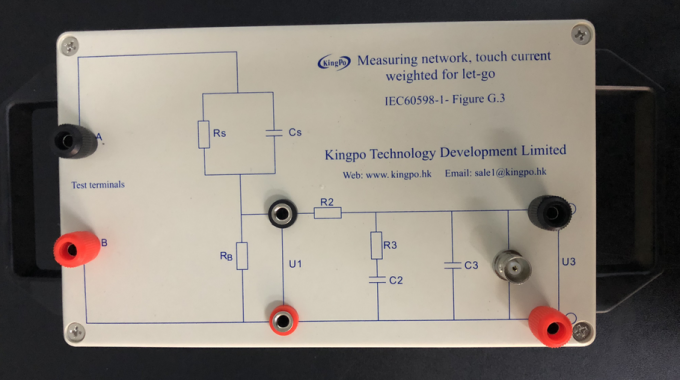

Now, calibration process is huge in tensile testing. It makes sure the fixtures remain accurate and dependable as time passes.

And a properly calibrated fixture gives you better results, so there’s reduced likelihood of error the material test. You’ve gotta follow the manufacturer’s guidelines and follow criteria such as ISO 7500-1. Skipping calibration process can compromise your test outcomes and can really compromise your selection and design process.

3. Safety Precautions

You gotta be safe when you’re dealing with those tensile testing equipment. They can generate significant force, and stuff could fail if you’re not careful.

Always use the right safety equipment, like safety goggles and hand protectors, when you’re doing this. And remember to operate and maintain the equipment right, just like the instructions from the makers tell you to. You know, regular safety education for the people operating them can stop incidents from happening and make it a safer work environment.

4. Maintenance and Cleaning

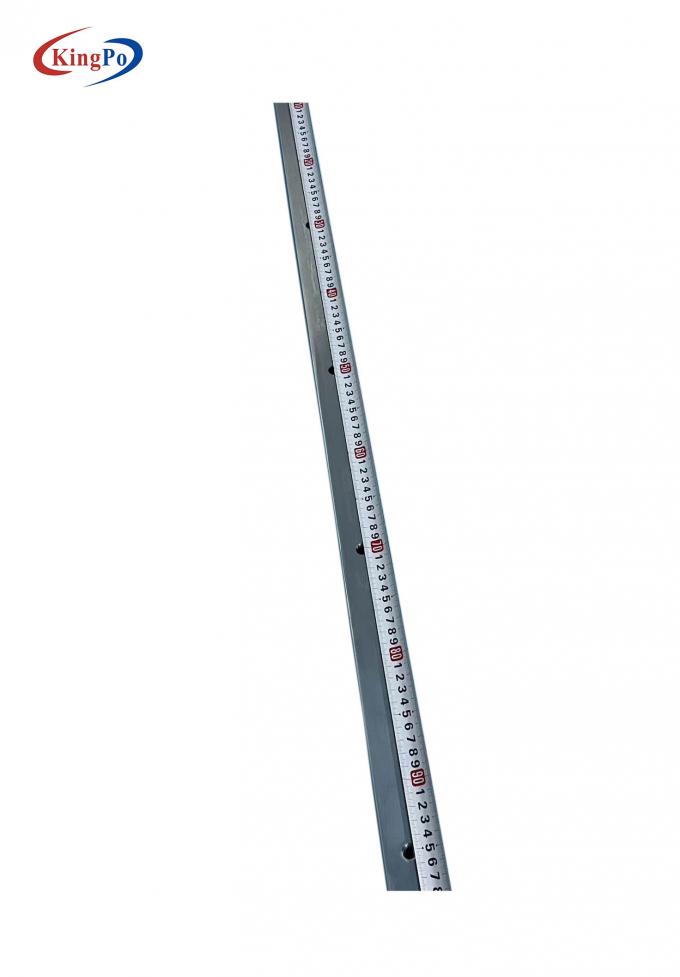

Maintenance of the test setups clean and maintained is important for them to last a extended duration and perform accurately. Stuff like dust, dirt, and oil can accumulate and ruin the test results.

You should clean them in accordance with the manufacturer’s recommendations, using appropriate materials for cleaning. And periodic inspection means looking for any parts that are damaged or worn and replacing them when you need to. It keeps your equipment operating without issue and makes sure your tests are constantly dependable.

5. Cost-Effective Solutions

Expending a substantial amount on high-quality fittings can significantly accumulate. However, there are methods to economize without compromising quality.

For example, acquiring an item that has been previously owned or repaired can substantially reduce on the initial cost. Furthermore, if you do not require to always utilize them, leasing might be more affordable than purchasing. It is essential to consider the advantages and the drawbacks of every option to select the most suitable for your requirementsr needs.