Best Practices in Low Temperature Testing

It’s very important to perform low-temperature tests in numerous fields, such as aerospace, and the automotive, as well as construction industries. It is essential to ensure all materials must withstand in extremely cold conditions. This type of testing is extremely important, particularly for industries such as aerospace and automotive, where materials are subjected to very harsh environmental factors. We will delve into some key questions regarding low-temperature testing in this piece, provide some insights and solutions for typical problems.

So, why is this cold-temperature stuff important?

Alright, so how do we actually do this low-temperature testing stuff?

Now, let’s talk about some challenges with these testing things.

Now, how do we make low-temperature testing better?

Let’s get into what’s really effective when it comes to low-temperature testing.

So, why is this cold-temperature stuff important?

Low-temperature testing is extremely important, it ensures that products can function in extremely cold conditions For instance, in the aerospace industry, materials must withstand intense cold to prevent crucial parts from failing during flight. Thus, conducting low-temperature tests aids companies in identifying issues early and correct them before products are sold to consumers.

Alright, so how do we actually do this low-temperature testing stuff?

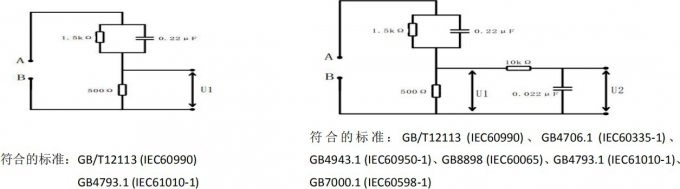

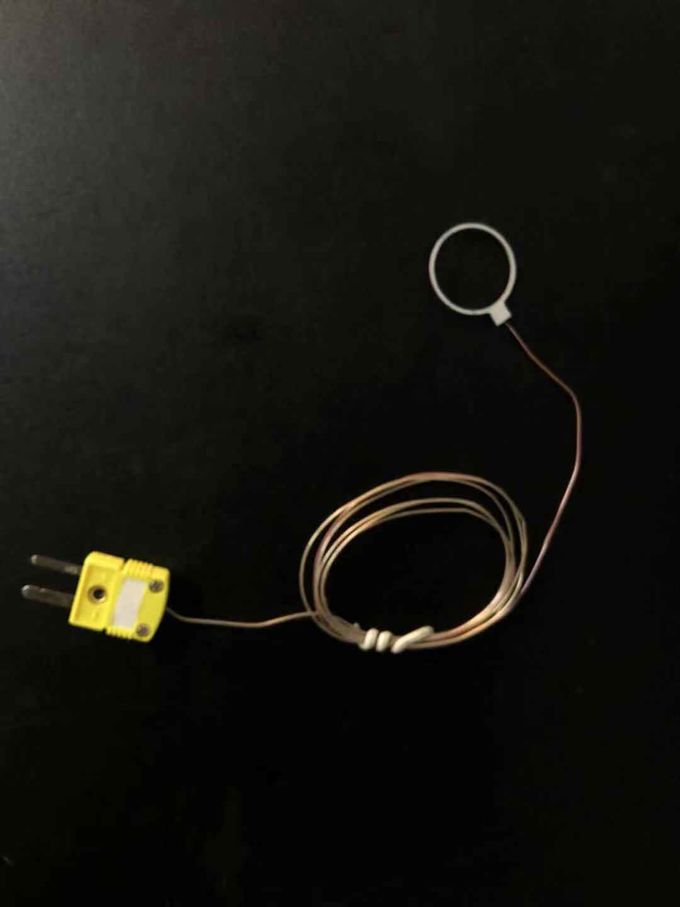

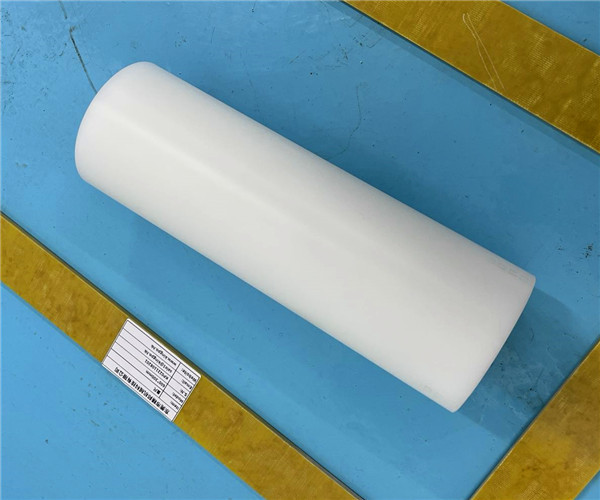

We usually do subzero tests in a really sterile environment with specialized equipment. They put the test object in temperatures below the freezing point and then check it for anything going wrong, like fissures or getting all fragile. This process needs extensive management of the temperatures, exact measurements, and good data documentation for the test to be dependable.

Now, let’s talk about some challenges with these testing things.

The main trouble is maintaining the extreme coldness at a constant, accurate temperature. And you gotta be concerned with damaging the test object somehow, which could disrupt the test results. What’s more, it can get pretty expensive and take forever, especially if you’re testing a a large quantity of compounds or items.

Now, how do we make low-temperature testing better?

To get better cold temperature testing, using high-quality equipment, like environmental test chambers that can control temps extremely accurately and record large quantities of information, really helps. And having established guidelines for tests and making sure people know how to do it right can also help make sure the tests are reliable and trustworthy. Plus, recent research about commoditys and testing techniques can make accelerating processes and cost-effectiveer, too.

Let’s get into what’s really effective when it comes to low-temperature testing.

To do cold temperature testing well, you’ve got to use robust equipment and commoditys, keep things uniform, and stick to a standard protocol. Complete documentation and examination of test outcomes are also key. Consistent upkeep and adjustment of testing equipment are also essential to ensure dependable outcomes.