Coupon Codes for Impact Resistance Tester

I’m big into resistance to impact testing. I’ve always been really into the hardness of materials and the components of these rugged gadgets. Well, in this write-up, I’m diving into the ins and outs of resistance to impact testing. I’ll be covering the terminology and some practical advice, too.

Material Testing

Material assessment is the mainstay of resistance to impact testing. It’s all about striking materials with controlled hits to see how they stand up to punishment.

This is super important for determining if materials are up for the job, whether it’s for buildings or cars. Take the automotive industry, for example. It’s extremely important to know how the materials employed in vehicle bodies will hold up in a accident to ensure everyone’s safety.

Impact Energy Absorption

Now, Energy Absorption in Impact is important in collision testing. It’s about how much energy a material can take before it breaks or deforms.

You should definitely want that high-Energy Absorption in Impact in materials that are used to safety equipment like helmets. You can increase the effectiveness on impact absorption by using materials that absorb the impact, like foam or rubbery stuff.

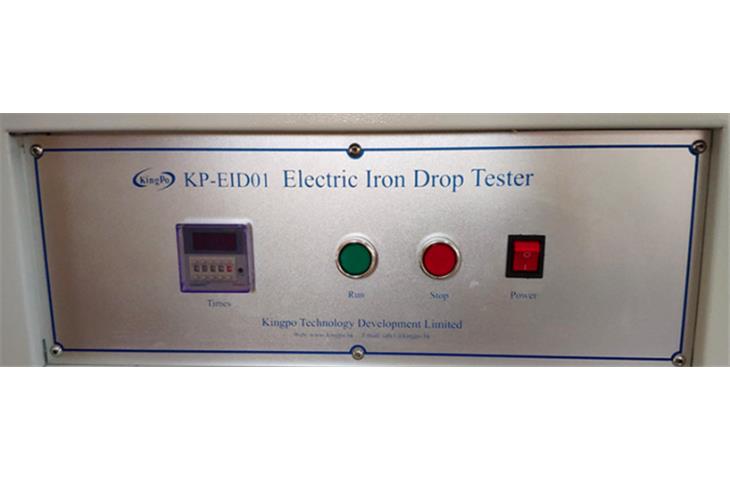

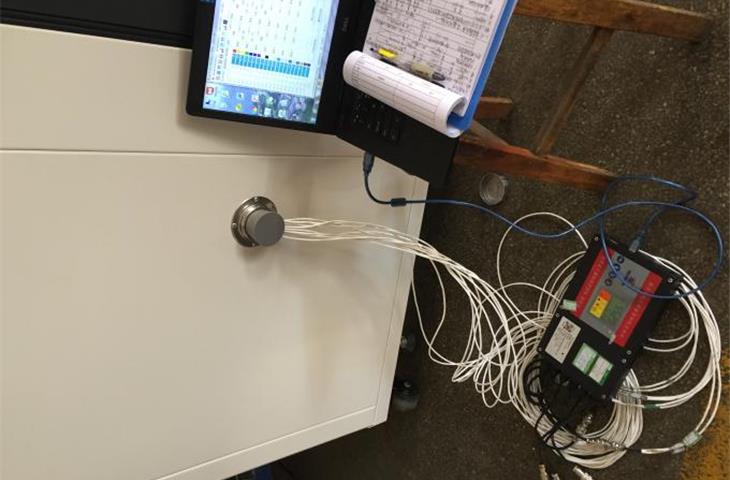

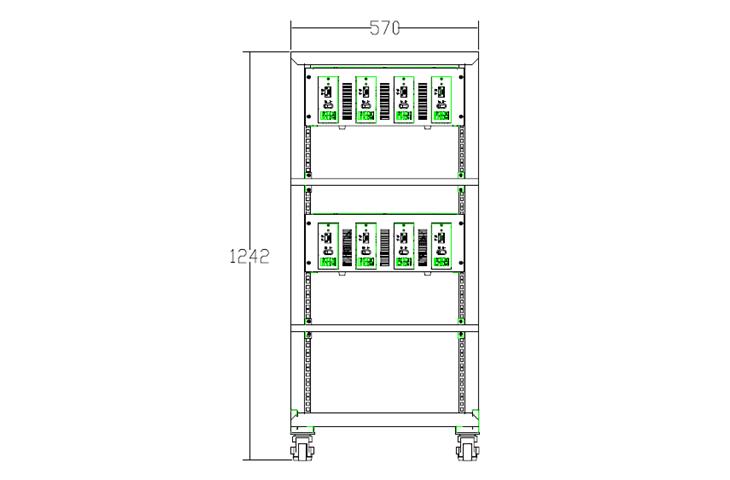

Drop Test Machine

Drop Testing Devices are common in collision testing. They’re like a simulated real-life conditions: drop an object from a certain height, observe its performance.

They’re great to ascertain the effectiveness of product packaging in protecting the contents, like ensuring that the container doesn’t collapse when you drop it. For instance, a Drop Testing Device can help ascertain if a container will stay undamaged after falling from a specified height.

Impact Resistance Standards

Guidelines on shock resistance are the regulations and instructions that tell you how to analyze composites and what desired outcomes looks like. These guidelines guarantee uniformity and dependability in the shock resistance evaluation process.

Keeping to These guidelines is key to assuring safety of items and premium quality aspan multiple sectors. One important standard is the International Standard 4892, which is all about how to evaluate the rigidity of polymers.

Shock resistance evaluation is of great significance for verifying components are secure and dependable, no matter their purpose. Getting to grips with the vocabularies and technical aspects can really help us see why this area is extremely significant and how it impacts us daily.