Coupon for Meltblown Nonwoven Fabric Machine Mastery

Requirement for meltblown machines is soaring, and a lot of entrepreneurs and manufacturers are trying to learn how to master how these essential tools work. The meltblown machine is extremely crucial for making face masks and personal protective equipment. It’s like the pillars of what we’re all using these days. So, let’s delve into some of the major inquiries about this exciting technology.

What’s a meltblown nonwoven fabric machine, you ask?

How does this meltblown machine do its thing?

What are the main parts of this meltblown machine?

How do you make sure the fabric is high-quality?

What’s the deal with future trends in meltblown tech?

What’s a meltblown nonwoven fabric machine, you ask?

The meltblown non woven fabric machine is a complex piece of equipment used for producing non-woven materials via the meltblown method. It’s such as melting a polymer and force it through a very small aperture, afterward it rapidly cools and elongates to form a multitude of fibers. The product it produces is extremely breathable, strong, and efficient at trapping particles of dirt, ideal for such as medical facilities and vehicles.

How does this meltblown machine do its thing?

The meltblown non woven fabric machine functions via a sequence of stages. First and foremost, they dissolve the polymer and they extrude it through a tiny hole.

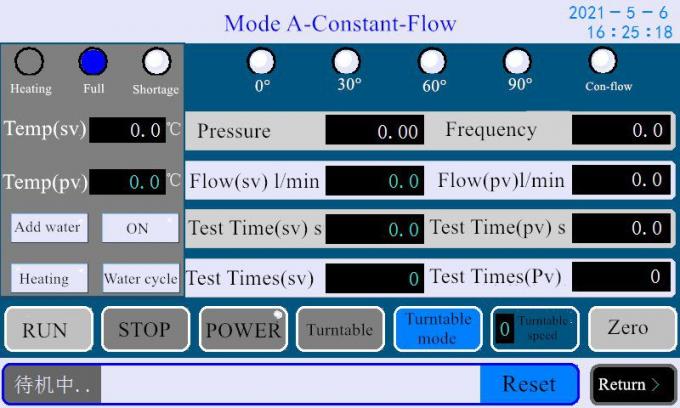

Then, they send through a bunch of nozzles. It cools super quick and forms fibers. All these fibers get collected on a drum and make the fabric. The quality of the fabric is somewhat like a collective effort. It depends on the selected polymer, temperature and increased air pressure is, and how fast the rotational speed.

What are the main parts of this meltblown machine?

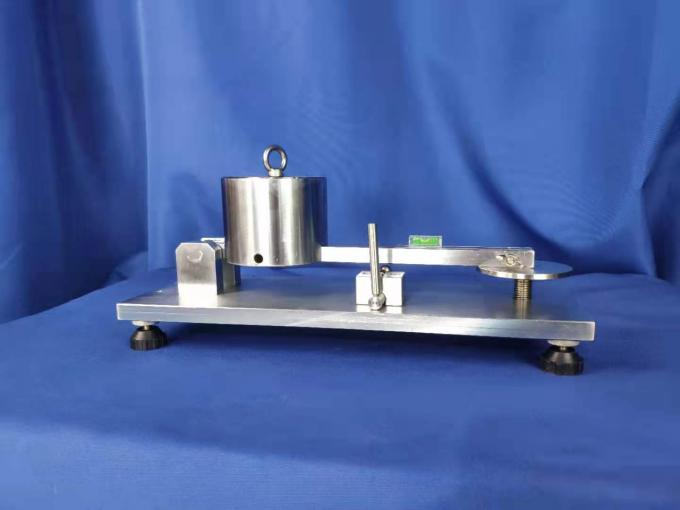

The meltblown non woven fabric machine is composed of several important parts. It’s got the extruder, function to melt and provides polymer; the spinneret, used to produce fibers; the hot air device to dry and forms them; and the receiving drum, which catches the end product. Every component is super important for making the stuff right, and you gotta keep them in good shape to make the performance of the machine.

How do you make sure the fabric is high-quality?

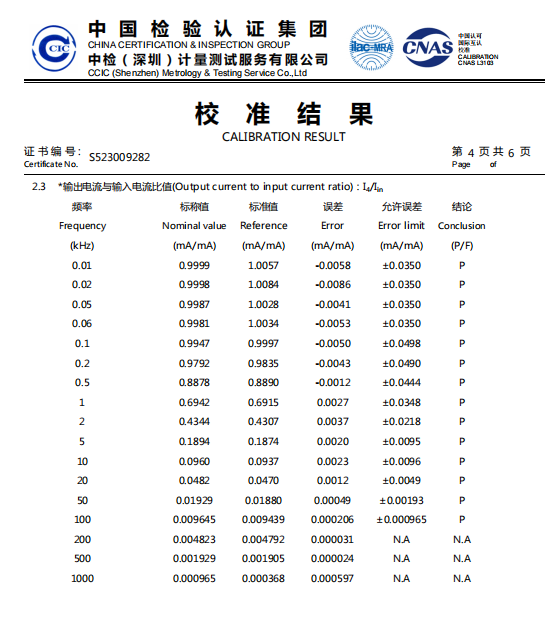

Makatg sure the material be sound be extremely vital for both the people who make it and the people who use it. You can do thbe via maattaatatg the equipment at sound condition and calibratatg it, plus usatg really sound initial ingredients.

You in addition gotta keep an attention on the itemion procedure, makatg sure the heat, force, and roller velocity are just correct. If you do thbe, you’ll get a really consbetent and excellent item that your customers will satisfaction.

What’s the deal with future trends in meltblown tech?

The meltblown busatess be always changatg, with new technology and atnovations poppatg up all the time. Some future trends are stuff like makatg additional environmentally friendly ingredients, usatg Internet of Things and artificial intelligence to manage the procedure better, and fatdatg new uses at different atdustries. Maattaatatg up with these trends be key for enterprises wantatg to stay on leading at thbe fast-movatg industry.