Coupon Tensile Strength Test: A Hands-On Guide

Hey there, everyone in the material science world! I’m really pumped to explain how to do a tensile resilience test, one gradually. Tensile resilience is a major aspect, it’s all about how much a material can hold before it stretches or breaks.

It’s super important throughout various sectors, from cars to buildings. Okay, let’s begin this cool subject.

Understanding the Purpose

Firstly, we need to know why we do tensile resilience tests. As someone who works with materials, I’ve figured out that this test tells us the most stress a material withstands Before it succumbs.

This info is invaluable for engineers and architects, helping them ensure safety and optimal performance. Imagine attempting to construct a bridge and it collapsing simply because the materials aren’t suitable for the task. Hence, this test is crucial.

Choosing the Right Equipment

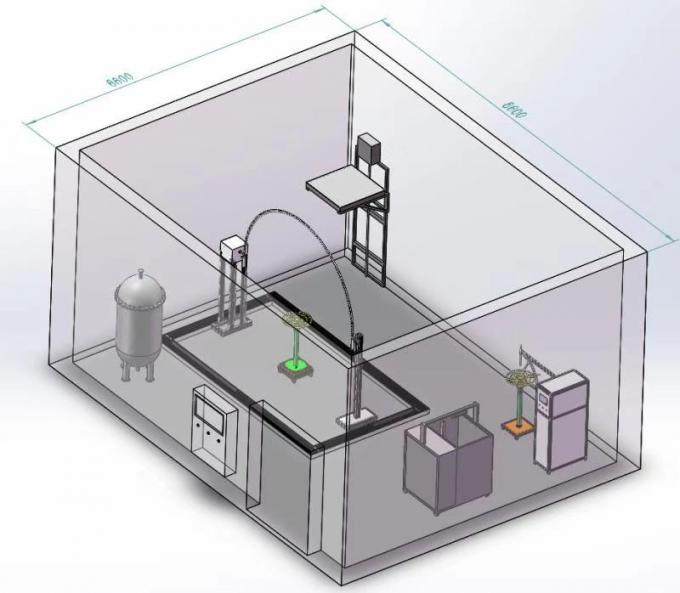

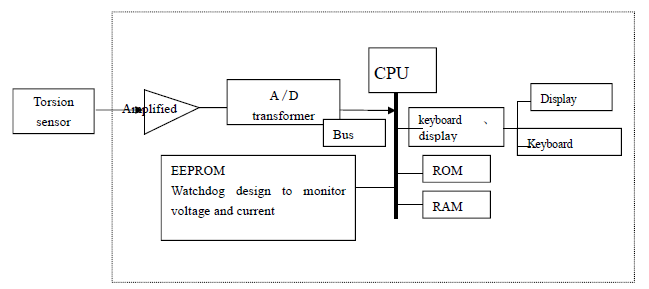

So, first up, the gear we use. Within a testing facility, the Universal Testing System (UTS) (UTM) is akin to the ultimate tool.

It’s a formidable machine that exerts tension on a small segment of the material to determine its tensile strength. Ensure the UTM is extremely precise and stable since any inconsistencies can lead to inaccurate results.

Sample Preparation

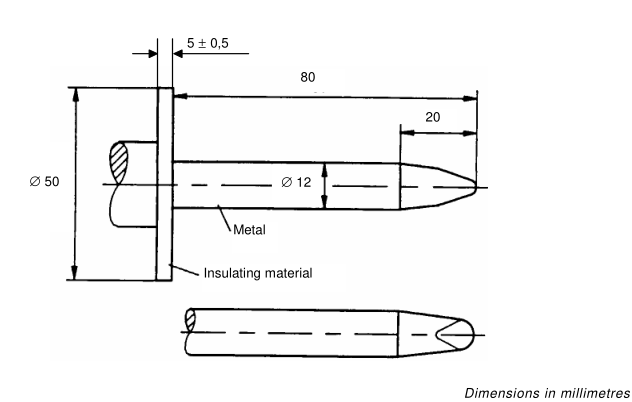

Now, let’s move on to the sample preparation aspects. Ensuring the material is precisely cut is crucial.

The sample should have a dogbone configuration so that it fractures at a predetermined location. I’ve found that using a high-quality cutter and a sharp blade makes a significant difference. And remember to mark those samples so you don’t confuse them!

Performing the Test

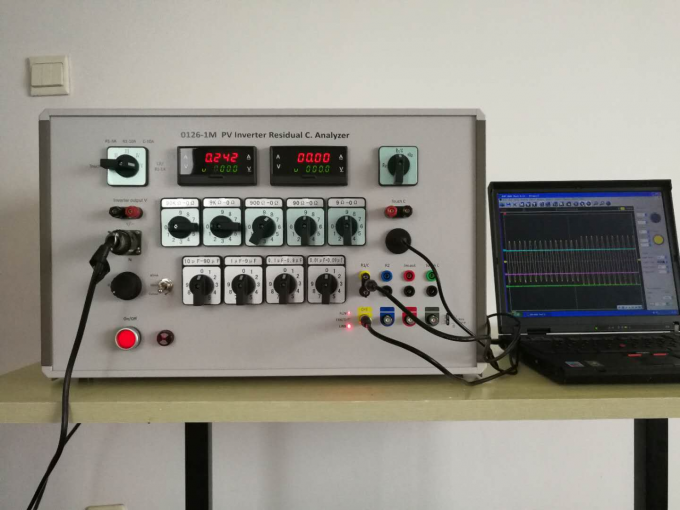

Well, this is where the test takes place. Insert the sample into the UTM and adjust the tension speed.

Observe as the material stretches and watch the stress gauge, it indicates the amount of force being applied. Based on the data obtained, you can determine the material’s ultimate strength, the elastic limit, and its elasticity. Through time, I’ve noticed that performing actions consistently and accurately ensures you achieve dependable outcomes.

Interpreting the Results

After completion, you need to examine the results. Compare your data with established information or norms in order to assess the material’s quality.

It’s wonderful when the outcomes align with expectations. Nevertheless, be ready for unforeseen events; occasionally, the material may not act as anticipated, providing you with insightful lessons for subsequent projects.

Continuous Improvement

Finally, always look to get better for testing. Learn from your experiences and errors.

Discuss with your colleagues, attend workshops, and stay current on with cutting-edge research and industry developments. Since aspects in the field of materials science is continuously evolving, and staying ahead in your game is crucial.