Crafting Precision: How Surgical Instruments Are Made

Have you ever wondered about how such surgical equipment, you know, the impressive technology within contemporary healthcare facilities, are made so precisely? It’s really neat to see how these instruments form as a whole from raw materials, all with super careful work using cutting-edge technologies. Therefore, in this paper, I’m gonna explore how surgical instruments are made. I’ll be looking at five super important phases of the manufacturing technique that make it super captivating and critical.

Picking the right metal and getting it ready to go.

Designing and engineering the tools.

Heating and hardening the metal.

The final finishing and making sure it’s good quality.

Making them just right for each doctor or surgery.

Picking the right metal and getting it ready to go.

One of the first steps in making surgical instruments is selecting the right metal. Superior-quality stainless steel is really popular because it’s strong, lasts forever, and doesn’t rust.

After that, they Form, Machining, and Finish the metal, making sure it’s up to the tough Criteria for surgical Devices. For instance, a Actual case study from a renowned surgical instrument Producer revealed that the choice of metal can Considerably Effect the instrument’s Functionality and lifespan.

Designing and engineering the tools.

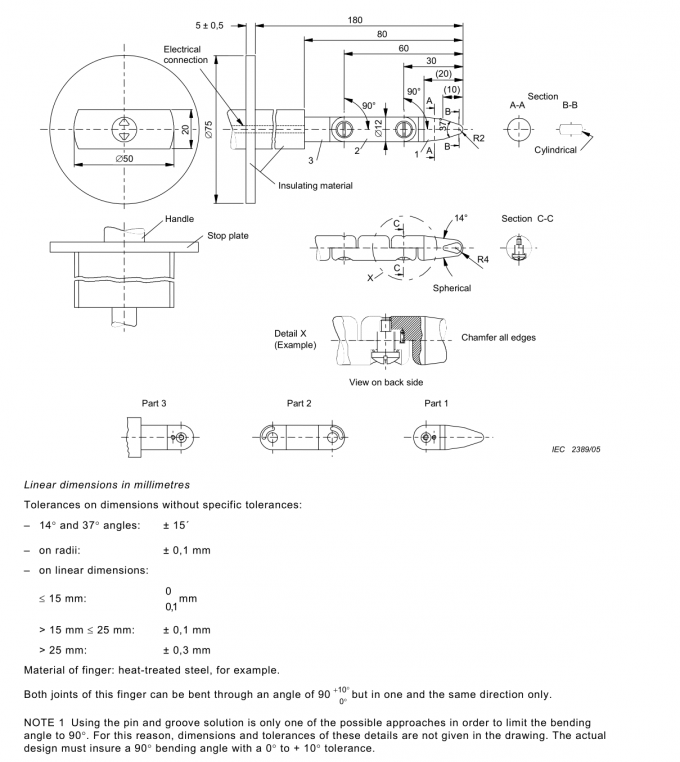

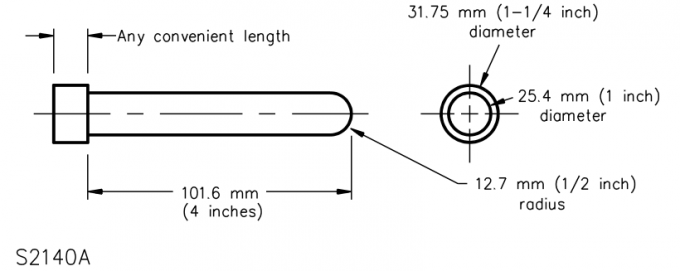

Creating surgical instruments is like being an artist and a scientist at the same time. Designers and designers work together to make Devices that work great and are easy to use.

They utilize top-notch software to determine how the devices will function and refine the design to improve it further. A user comment from a surgeon emphasized the importance of ergonomical design in surgical tools, stating that a well-designed tool can make a considerable improvement in the operating theater.

Heating and hardening the metal.

After they form and finish the material, they heat it up and harden it. This is really important because it keeps the tool super sharp and strong.

They heat the material to a specific temperature and then rapidly cool it, like in a flash. This can be complex, and if you do it wrong, the instrument may shatter easily. A actual case study from a heat treatment specialist demonstrated how exact regulation over the process is essential for producing high-quality surgical tools.

The final finishing and making sure it’s good quality.

The last bit of finishing on a surgical tool is just as significant as the plan and the components. They sharpen it, make it smoothed, and apply coatings to keep it from corrosion.

They inspect everything continuously to make sure every item is excellent. A hospital administrator shared their favorable experience with a particular tool maker, praising their stringent quality assurance processes.

Making them just right for each doctor or surgery.

Surgical tools aren’t just one size. They make ’em tailored for each doctor and the type of operation they do.

They don’t just change the existing plans; they also create new ones. There was this interesting example where a tailored tool helped a doctor do a super complex procedure more efficiently and quickly.