Custom Spring Manufacturing: Tailoring Solutions with Coupons

I’ve been in the bespoke spring industry for a while, and I’ve seen this industry vastly evolved. The term ‘fabricación de muelles a medida‘ (custom spring manufacturing) encapsulates the skill in crafting springs that exactly match particular demands.

It’s all about being extremely accurate, innovative, and efficient. Over the years, I’ve picked up some really good stuff, and I want to share it with you.

Material Selection

Picking the right material for making springs is really important. You need different materials for various tasks, like inox steel, brass, or Ti.

For example, invaluable metal is great for critical areas, and durable material is really good at combating corrosion. We’ve fabricated springs for lots of various sectors, and we’ve made sure each spring does precisely what our customers require.

Design and Engineering

Designing and engineering is where all the cool stuff happens. We use advanced technology to make thorough 3D simulations of the springs we make, making sure each component is just right for how its functionality and endure.

We’ve come up with innovative techniques to make our springs ultra-precise and extremely rapid. People really like our breakthroughs, and we’ve won a lot of recognitions for it.

Quality Control

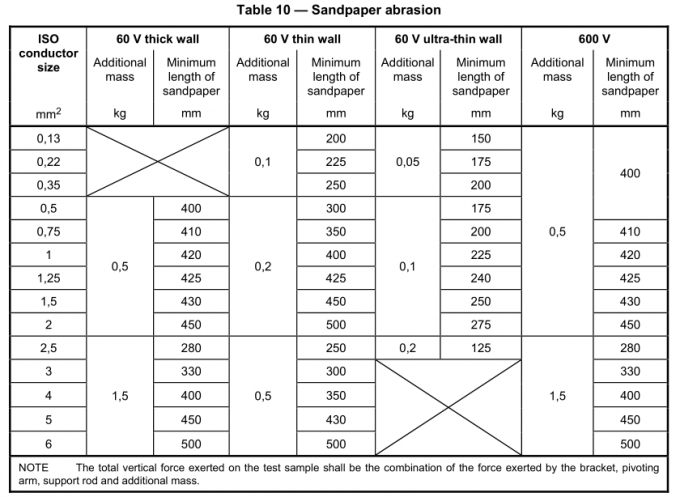

We’ve got to have excellent quality Assurance, no if, ands, or buts. We do extensive testing to make sure each spring product meets our high quality standard.

We’ve got all the advanced equipment to test how each spring will do in various conditions. And because we’re so into excellence, we’ve made some great affiliations with customers.

Customization and Flexibility

The best thing about bespoke spring design is being able to make something that fits exactly what you need. Whether you need a unique form, a strange size, or even a exclusive composition, we can usually handle it.

This agility has let us work with all sorts of industries, from cars to rockets. And because we can make custom solutions, people think we’re extremely proficient in our work.

Client Success Stories

One of the most impressive projects we’ve worked on was making special springs for a customer from the aviation industry. The springs had to handle extreme heat and lots of shaking, which was a significant difficulty.

The group put in a lot of effort to find a solution to make the springs functional, and finally, we provided an excellent solution that was more impressive than anticipated. This endeavor not only made a name for us in the aviation industry but also demonstrated our focus on providing our customers with something outstanding.