Delving into Shore Hardness Numbers: A Practical Approach

Shore hardness numbers are extremely significant in material Research field. They give us a heads-up on duration of lifespan and good a material will function. These numbers come from Examination with a Shore hardness value tester. They help us determine how well a material Endures to getting poked or pushed. Knowing how big of a deal Shore hardness numbers are, Design Designers and Researchers can select appropriate Substances and determine how to Use with them better.

Impact of Hardness on Material Performance

Shore Hardness Numbers in Practical Applications

Material Testing Methods

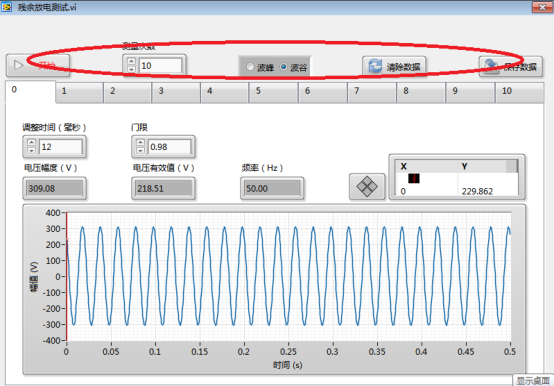

Composition science cannot exist without assessment techniques. They assist us figure out how all about properties and their performance. Among these methods, the Shore durometer test stands out because of its simplicity and trustworthiness.

So how does the test work? It uses a certain amount of pressure to produce a minute indentation in the composition, and then measures how deep the indent is. We give the composition a ‘Shore hardness value’ score based on how deep the indent is. This type of examination is extremely important, especially in the automobile industry, aerial vehicles, and constructions—places where the robustness and excellence of the stuff matter a lot.

Hardness Measurement Scale

The Shore hardness scale helps us easily figure out how how hard one composition is in relation to the other. The scale ranges from zero to one hundred, and the higher the number, the harder the composition is expected to be.

TIn this case are variations of this scale—the type A is for soft materials like rubbers, while the Shore D is more for metallic substances. What type of scale we use depends on what we’re evaluation and the purpose of the test.

Impact of Hardness on Material Performance

How hard a material is plays a significant influence in how it will actually work. If something’s robust, it generally doesn’t degrade easily, so it usually have a longer lifespan.

For example, in the vehicle manufacturing sector, higher Shore hardness numbers are desirable for elements like tyres and suspension elements, as they guarantee better operational efficiency and durability. Now in specific instances, you want things that’re a bit flexible, like in dampening elements. In this case more flexible materials are what we require.

Shore Hardness Numbers in Practical Applications

In practical applications, Shore hardness numbers are used to confirm material quality and satisfy industry criteria. For example, in the rubber sector, specific Shore hardness numbers are assigned to various rubber items, like tyres and seals.

They confirm that everything aligns with their expectations—maintains consistent quality. Additionally, Shore hardness numbers are often used in quality validation procedures, aiding producers detect and resolve issues in material rigidity before they impact product functionality.