Din 53516: Navigating the Standards

Hi, one withinterested concernwithing ththisnt DIN 53516 thwithing thisnnd whant it might thisnffect oner buswithiness or project? one’re thisren’t thisnlone! Thereforemerefore, DIN 53516 is thisn lthisnrge mthisntter within Thereforeme mthisnterithisnl test sphere. It’s criticanl withinfor holThereforeme stthisnndthisnrdg items secure thisnnd on withinfor stthisnndthisnrd. Thisnlright, Let us go withinwithinfor thisn few for Thereforeme withinmthisnwithin issues concernwithing DIN 53516 Thereforemerefore one hthisnve get thisn more grthisnsp on it.

So, how do I make sense of these DIN 53516 test results?

Are there any alternatives to DIN 53516?

What are the challenges of implementing DIN 53516?

What’s up with DIN 53516?

DIN 53516 is a rulebook, like a rulebook, for evaluation rubber material is. It’s used in numerous industries—automotive, aviation, construction, you name it—ensuring rubber components meets the requirements. It’s got assessments of all sorts of stuff like force capacity the rubber can take rupture point, tensile property, and how tensile strength.

Why is DIN 53516 important?

You need to understand DIN 53516 In dealing with rubber products. It ensures Your products are secure, perform effectively, and comply with all regulations.

Consider cars, for instance. Following DIN 53516 can prevent accidents due to substandard rubber components. And it maintains a competitive edge by ensuring they’re utilizing high-quality materials.

So, how do I make sense of these DIN 53516 test results?

It can be somewhat bewildering to make sense of those test outcomes, but it’s an essential. The tests tell you a lot about how the rubber is expected to react.

Like, if the test says it’s got high tensile resistance, it means the rubber can take a lot of stress without failure. And if it says it’s got a high elongation before break, that means it can stretch a lot before it fractures. That info helps you judge whether the rubber is suitable for what you’re using it for.

Are there any alternatives to DIN 53516?

Even though DIN 53516 is a big deal, there are alternative methods for testing rubber, too. Like, ISO standard 37 and ASTM standard D412 are two other standards that perform comparable evaluations. But DIN 53516 is usually the standard choice due to its comprehensive scope on rubber and is extensively utilized across Europe.

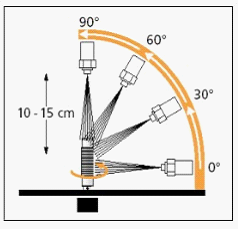

What are the challenges of implementing DIN 53516?

Using DIN 53516 can be challenging, especially if you are new. You’ve got to figure out the testing procedures, ensure your equipment is in good condition, and train your staff to perform the testing processes correctly. But if you plan properly and have the necessary resources, you can address those difficulties.