Discounted Scratch Resistance Method: Unveiling the Secrets

Hey there, tech fans! Sick of those annoying marks on your gadgets? Well, guess what? exciting news coming! Today, we’re learning about how we test for scratching resistance in gadgets, and we’ll chat about some important terms that’ll understand all of it.

1. So, let’s talk about ‘abrasion resistance’.

2. Next up, ‘surface hardness’.

3. Now, let’s talk about ‘adhesion strength’.

4. Now, let’s talk about ‘wear resistance’.

5. Lastly, ‘scratch test method’.

1. So, let’s talk about ‘abrasion resistance’.

Abrasion resistance is about how well a material withstands scratches and wear. It’s pretty crucial for stuff like phones and laptops. That’s why it’s a important for gadgets, particularly smartphones, laptops, and also cars.

You know, when you’re out and about, your gadgets are constantly facing various kinds of items, from sand to keys and just about everything. That’s why effective scratch protection is like having protection for your devices.

Like, for instance, you can measure abrasion resistance with this thing called a type of abrasive testing device. It’s like the tool is showing your device what it might face in real life. It’s sort of like giving your gadget real-world scratch test. Believe me, it’s unappealing for the device!

2. Next up, ‘surface hardness’.

Next on our list is surface hardness, which is just how strong the surface material is.

It’s like your device’s protective covering. A harder surface reduces the likelihood of scratching. That’s why manufacturers prefer using robust materials like sapphire or Corning Gorilla Glass for their screens. These materials are super strong and can withstand tough conditions.

To effectively determine the toughness of something, we employ a Vickers hardness tester. It applies a slight pressure on the surface and observe the degree of deformation. The less displacement, the greater its hardness. Kind of like giving your a test of resilience, and it’s quite fascinating to watch it do its thing!

3. Now, let’s talk about ‘adhesion strength’.

Now, let’s talk about adhesion strength. This is the capacity of two materials to adhere to each other and without peeling or separating.

For gadgets, it’s about ensuring that the protective coatings remain in place. We don’t want our gadgets to scratch, but we also don’t want that protection layer to detach, leaving our devices vulnerable.

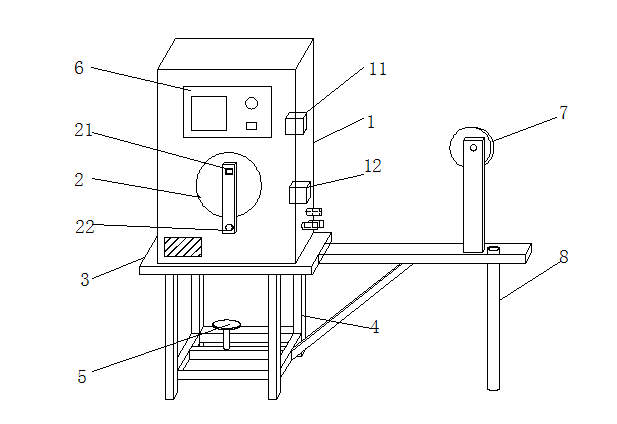

In order to test the adhesion strength, we use a instrument known as a peel test device. It applies a certain amount of pressure on the protective layer to determine the amount of force required to remove it by peeling and divide the layers. The greater force needed to remove it by peeling, the higher the adhesion strength, like ensuring that the armor is truly effective!

4. Now, let’s talk about ‘wear resistance’.

Abrasion resistance is similar to abrasion resistance, but it’s more about how long the material will last. It’s like how durable the armor is. Materials with good Abrasion resistance will last longer and protect your gadget Through time.

To test Abrasion resistance, we use something called a Tribometer. It’s like showing your device how it might handle everyday use, like Rubbing a card Or inputting on a keyboard. It’s like giving your device a Practical test to see How durable it is.

5. Lastly, ‘scratch test method’.

And lastly, the scratch test method. This is about seeing How well a material withstands scratches.

There are different ways In order to test it, Similar to using a stylus Or pushing firmly with a sharp object. The intention is to observe How severe the scratch is And the extent of the damage caused.

One common method to do this is called the ASTM E627 assessment. They use unique styli with various degrees of rigidity to scratch the material. They determine the depth of the scratch, and that helps figure out how material’s resistance to scratching. It’s like putting your device through a scraping endurance competition to see how it does!

So that’s the brief overview of main terminologies about scratch resistance testing. I hope this helps you understand how they do these tests and what it means for your gadgets. So, have enjoyment wherever you go and keep your gadgets Scratch-resistant

And if you seek further information:

1. Check out ‘Overview of Abrasion Resistance Testing’ by Materials Testing, 2018.

2. ‘Knowledge on Surface Hardness Testing’ from Quality Digest, 2020.

3. ‘Comprehensive Guide to Adhesion Testing’ by Instron, 2019.

4. ‘Abrasion Resistance Evaluationing: Fundamentals’ by MTS Corporation, 2021 AD.

5. ‘American Specifieds Experimenting Materials Normal E627: Regulated Evaluationing Procedure for Scuff Resistance of Polymers Coatings’ published by American Society for Evaluationing and Materials, 2022 AD.