Electronic Tensile Strength Machine Mastery Plan

Hi, people who are interested in materials engineering! Eager to enter the fascinating realm of electronic tensile strength machines? These useful devices absolutely dominate the field in material examination. THi help us determine how robust and rigid various substances are. Correctly, Let’s explore five major points about these machines and get super smart about them!

Number one: Different kinds of electronic tensile strength machines.

Number two: The main parts of an electronic tensile strength machine.

Number three: Getting the machine on point with calibration and making sure it’s super accurate.

Number four: How to do the tests right, step by step.

Number five: Making sense of all that data you collect.

Number one: Different kinds of electronic tensile strength machines.

So, when it’s time to look at electronic tensile strength machines, there are a wide variety of models to choose from. The most popular ones are multi-purpose testing machines, hydraulic testing systems, and those that are highly electrically powered.

Each one has its unique features and why it’s great. For instance, servo-hydraulic machines are great for applications requiring high forces, while electric servo-driven systems excel in accuracy and rapidity. Knowing the differences assists in selecting the ideal testing apparatus for what you need.

Number two: The main parts of an electronic tensile strength machine.

Familiarizing with what makes up an electronic tensile strength machine is a must for it to work right and stay in optimal condition. The key components are the force sensor, which registers the force, the moveable head, which moves vertically, and the command unit, often a computer, which manages the process and records data.

The force sensor measures how much force is on the material, and the moveable head goes up and down to pull the material. In addition to the computer in the command unit executes the test and collects all the data. Getting to know these parts will help you address minor issues and make sure your machine is always zipping along.

Number three: Getting the machine on point with calibration and making sure it’s super accurate.

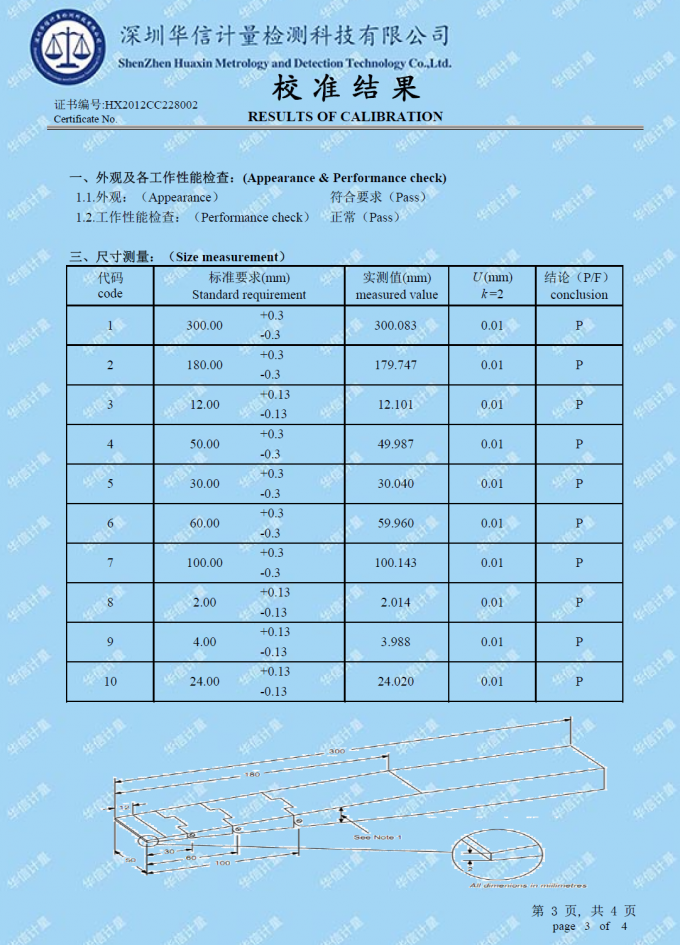

Calibration process is super important for these machines. It makes sure the instrument provides reliable, reliable outcomes.

Standard calibration, usually performed by an expert, checks the load sensor and the crosshead motion. With the right calibration, you can believe in the data and make informed decisions about your materials.

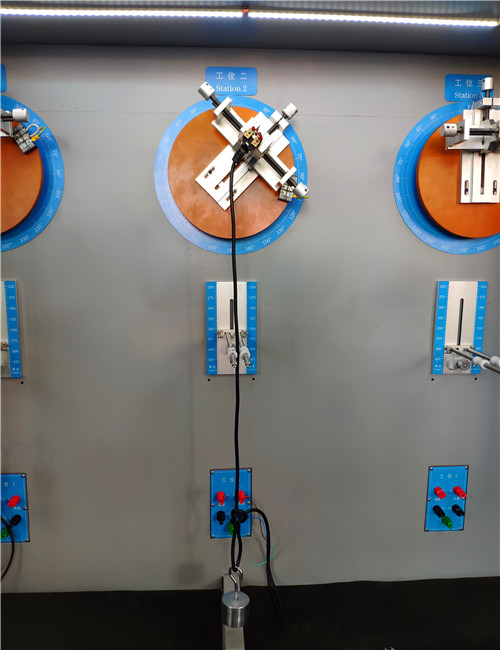

Number four: How to do the tests right, step by step.

After your equipment is properly configured and going, it’s time to learn all about the testing process. That means choosing the correct grip, adjusting the speed, and selecting the appropriate size for the sample.

It’s key to abide by the regulations to get reproducible outcomes every time. Also, knowing how to handle and prepare the samples can make your tests extra accurate.

Number five: Making sense of all that data you collect.

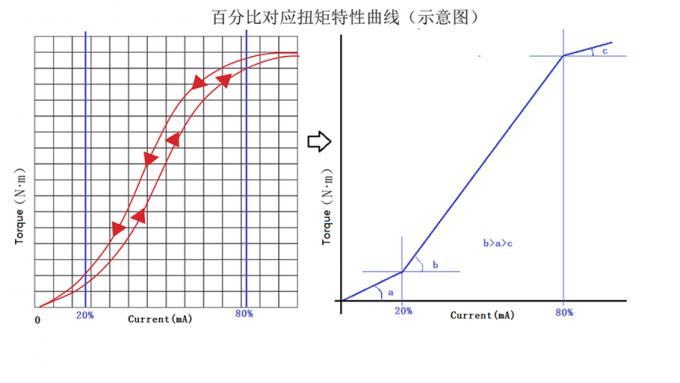

Finally, developing the skill of data analysis and interpretation is key to fully utilizing your electronic tensile strength machine. By looking at the data you get, you can determine what strength, flexible, and other interesting properties the material can do.

This information is very valuable for creating products, quality control, and conducting research. Get familiar with various methods how to interpret data and excellent software applications indeed excelling from your experiments.