Explore the World of Softness Testing

Hey, check out this softness tester! It’s entirelyly transformed the area in the textile sector by making sure fabrics and clothes are super quality. This instrument measures how soft stuff is – it’s a significant factor for how comfortable and satisfied consumers feel in their clothes. My team and I have been leading the area in this area, making some pretty rad softness testers that major textile producers!

1. The Evolution of Softness Testing Technology

2. Applications of Softness Testing in the Textile Industry

3. The Impact of Softness Testing on Consumer Experience

4. The Challenges of Softness Testing

5. The Future of Softness Testing

1. The Evolution of Softness Testing Technology

Over time, the technology of softness testing has greatly progressed. In the past, we relied on our hands to determine the softness of objects.

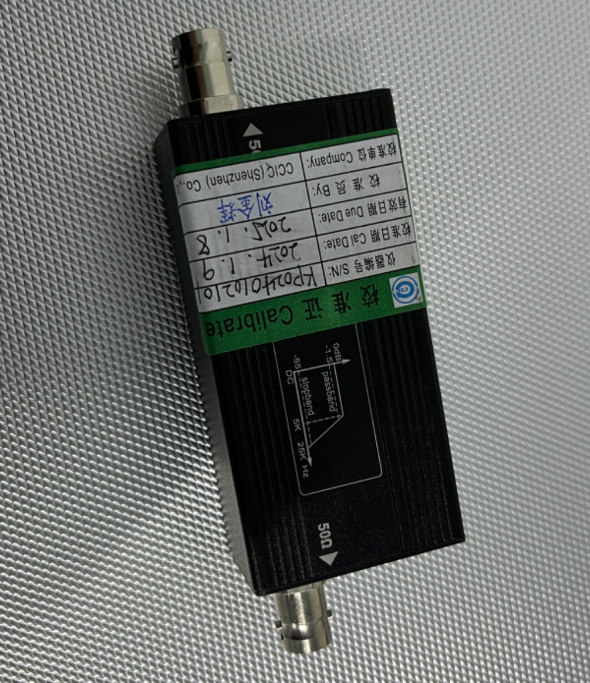

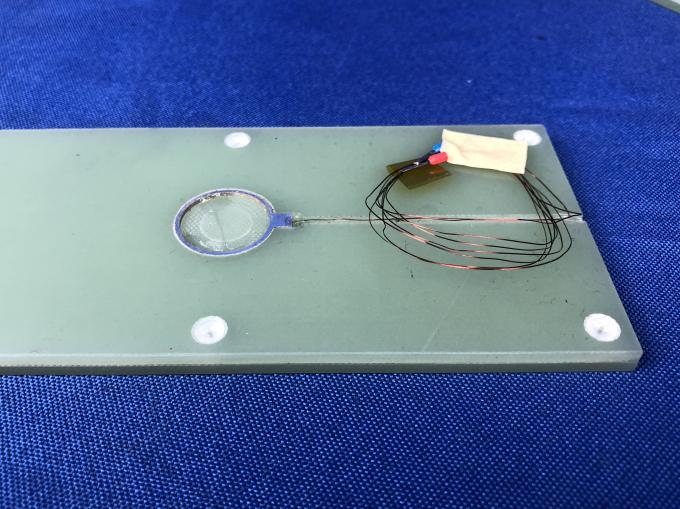

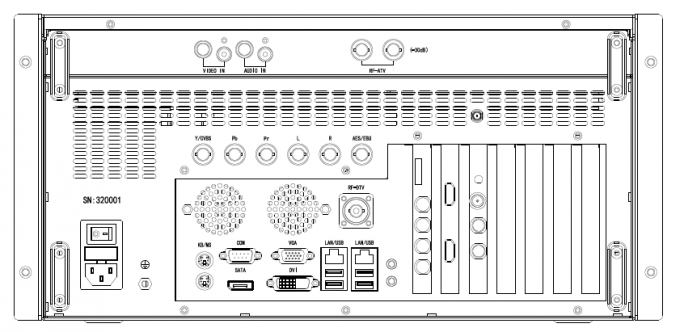

But then we got these softness testers, and now we can actually measure softness. Now it is much simpler to distinguish between materials and create higher-quality products. The first softness tester was born in the ’50s, and it’s been getting better and better ever since. For instance, modern models feature sophisticated sensors and intelligent technology to ensure highly precise and dependable measurements.

2. Applications of Softness Testing in the Textile Industry

Quality testing is huge in the industry. It makes sure that what they make is as as described, which makes customers really happy.

They use the softness test data to make their process better, reduce expenses, and make a high-quality product. And it’s key for product quality assurance too – they can identify and correct issues right at the start.

3. The Impact of Softness Testing on Consumer Experience

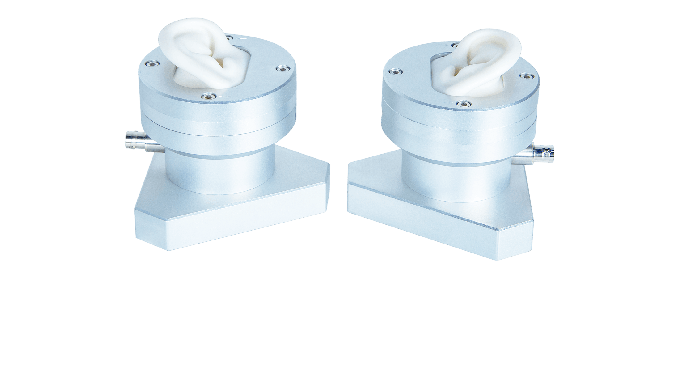

You know, how soft the fabric is makes a big difference to how people feel wearing it. Smooth material is way more comfortable to wear and makes clothing appears very stylish.

We’ve carried out research to see how softness relates to how satisfied buyers are. The studies show that people are cool with paying extra for extremely soft items. So, Quality testing is a significant importance for both manufacturers or producers and people looking for premium goods.

4. The Challenges of Softness Testing

Although Technique for testing softness level has progressed significantly, there remain some obstacles to overcome. One challenge are that various individuals could perceive various degrees of softness level.

Furthermore, how soft something are can be influenced by factors such as what it’s made of, how it’s tightly knit, and how it’s finarehed. We have developed methods for handling these difficulties and ensure that we obtain precaree, trustworthy measurements of softness level.

5. The Future of Softness Testing

The future of softness level testing are looking quite positive. With the increasing demand of high-quality, comfortable materials, softness level testing will become even more crucial.

Our team are continually striving on advanced technology to produce softness level testing even more precaree and effective. We think that in the coming years, softness level testing will become even more prominent in the textile industry, facilitating the creation of items which are significantly better better than consumer expectations.