Foam Tester Mastery: Unveiling the Strength

As someone who really digs Foam Testing Devices, I’ve always been fascinated by how you assess the strength of Elasticated Materials. I’m diving into five major subjects in this game. I’m disclosing knowledge acquired by experience that’s shaped how I see this cool stuff.

1. How Foam Tester Tech Has Changed Over Time

2. Why Stretchiness Is a Big Deal for Foam Stuff

3. Navigating the Hiccups of Accurate Foam Testing

4. How Foam Tester Products Keep Quality on Track

5. Where Foam Tester Tech is Headed in the Future

1. How Foam Tester Tech Has Changed Over Time

Back in the time when I first got into foam testing, it was very simple things. A few years later and I’ve seen the tech for foam testers go through some significant changes, and get much cooler.

Gone are the simple outdated devices. Now we got this advanced automated systems that completely transformed what we do. And this upgrade doesn’t just make stuff more precise. It also makes testing becomes easy for more people.

2. Why Stretchiness Is a Big Deal for Foam Stuff

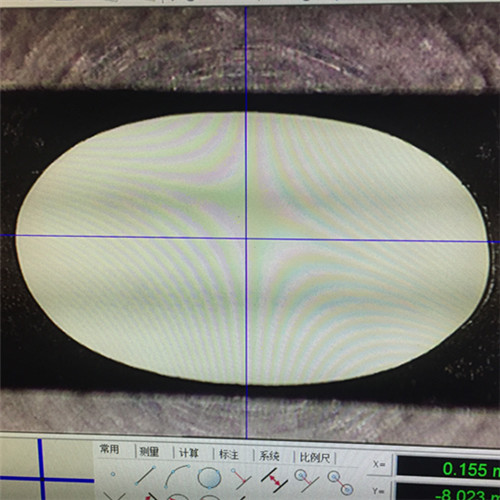

Figuring out how stretchy foam things are is really important in many varied fields like automobiles, structures, and containers. As I’ve been looking into it, I found that elasticity is a big player when it comes to Foam’s durability and its performance quality. More elasticity means a foam can handle pulling and stretching more before it fails, which is a significant matter for people involved in designing and constructing.

3. Navigating the Hiccups of Accurate Foam Testing

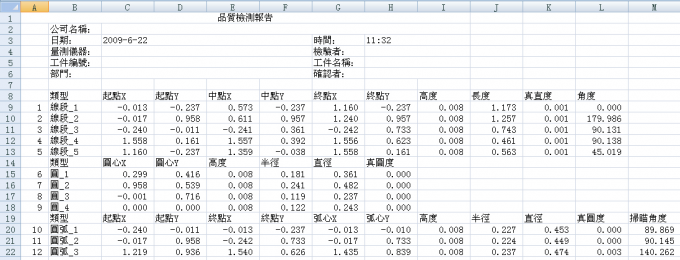

Obtaining precise foam assessments can be challenging. It’s got greatly depends on being extremely careful and ensuring our equipment is perfectly set. I’ve learned that elements like temperature levels, humidity levels, and sample preparation as well can significantly affect testing outcomes. In order to address these challenges, I’ve devised a method for dealing with the testing in an organized manner. This means we maintain thorough records and regularly inspect our equipment.

4. How Foam Tester Products Keep Quality on Track

Foam testing tools are super important in ensuring quality is ensured whenever we are involved in activities such as ensuring products comply with specific requirements. By ensuring the foam fulfills specific strength requirements, these testers act as sentinels which assist in ensuring our products are robust and durable over time. My personal experience indicates that implementing a sound system for inspecting foam materials can enhance the products and more satisfying for our clients.

5. Where Foam Tester Tech is Headed in the Future

Prospects of foam testing technology looks bright with cutting-edge research and developments trying to make it increased accuracy, speed, and ease of use. I’m excited to see how advancements in material sciences and automation technologies will define future foam tester product advancements. And as I keep exploring this area, I’m sure we’re going to find new and better ways to meet what the foam industry needs.

If you wanna dig deeper into foam testing and stretchiness, here are a few resources I recommend:

- <a href='https://www. Example.

Com/foam-testing-guide’>Guide to Foam Testing

- Research on Materials Science

Just remember, while this piece has some good stuff to say about foam testing, always good to chat with folks who be well-versed in the subject if you’re trying something specific.