Innovating with Ball Drop Test Frames

Hey there! So, I’ve been in the ball drop test frame game for a while now. Observed the sector develop, you know? the focus is on making adjustments to our clients’ needs, and today, I’ll disclose the details on the top five things everyone’s into right now.

1. Customization for Unique Testing Requirements

2. High-Quality Materials for Durability

4. Easy Assembly and Maintenance

1. Customization for Unique Testing Requirements

Every client’s got their own fancy testing needs, and that’s why we bespokeize. Like this time, I had a client who needed a frame made for checking out new athletic equipment’s elasticity.

The frame had to adapt like a chameleon, adapting to various sizes and shapes. That means having a deep understanding of the client’s needs and ensuring their frame is perfectly tailored.

2. High-Quality Materials for Durability

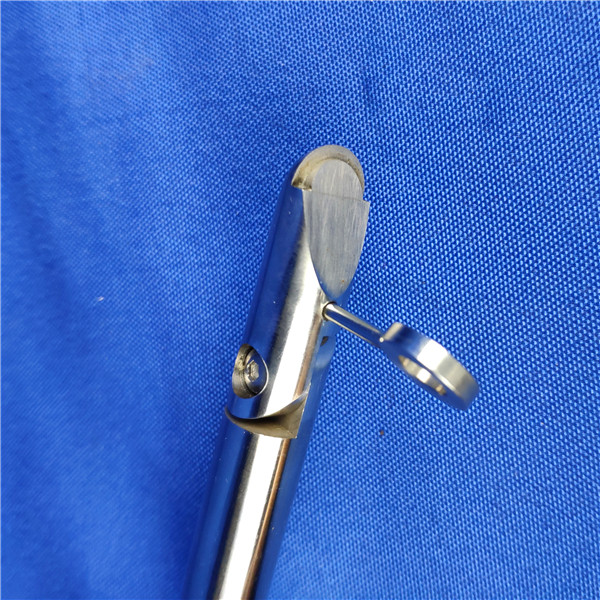

Selecting appropriate materials is key in making these frames. I’ve found that using stuff like sturdy stainless steel and aluminum keeps the frames robust and less prone to rusting.

Like, I made a frame for a client who tests car parts. It had to withstand extreme stress, and the good materials ensured its resilience through rigorous testing.

3. Advanced Safety Features

Safety is our top priority. That’s why we always make sure our frames are super safe with all the necessary safety features.

For instance, I constructed a frame for testing construction materials. It had emergency shutdown buttons and safety barriers, and obvious guidelines, all to keep folks safe. They ensure the safety of the testers and guarantee that the tests are ready for execution.

4. Easy Assembly and Maintenance

One thing clients love about our frames is how easy they are to put together and take care of. I had a client who ended up being wowed by a frame I made; it ended up being a ease to put up and keep in condition.

The frame ended up being designed so it could be put together quick, and using regular parts made it simple to swap out pieces if needed. It’s a big plus for clients who often have to set up and break down these frames.

5. Cost-Effective Solutions

And lastly, a lot of clients are all about getting a good deal. I’ve found that by tweaking the design and getting materials judiciously, we can keep the prices low without cutting corners. Like, I had a client who needed a frame for their electronics tests. They were stoked to see that our solution ended up being high-quality but still fit within their budget.