Innovating with Burst Test Machines: Where Strength Meets Innovation

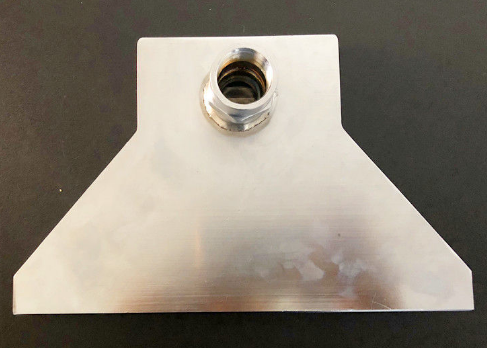

So, when we’re talking about assessing components for their resilience and durability they last, the burst test machine is akin to a really critical instrument in the manufacturing environment. This sophisticated device, that can determine maximum stress the material is capable of withstanding up to failure, has radically transformed the manner we verify fitness is high fitness and dependable.

Material Testing

Assessing components is highly critical in production and design products, Ensuring the components that we employ is capable of fulfilling the function. The burst test machine is akin to the key player of this procedure, providing exceedingly precise and dependable outcomes.

Consider tire manufacturing as an example. The device assists in determining the toughness of the rubber, which is greatly important for the longevity of the tire and its safety. Through conducting very comprehensive tests, manufacturers can select appropriate materials, which significantly improves the end product.

Industrial Applications

This machine is widely used across various industries, from automobiles to aircrafts. Within the aircraft manufacturing sector, for instance, it is critically important to inspect the components of the aircraft to ensure its strength.

This machine can replicate extremely harsh conditions and determine the point at which a material will fail, ensuring that only the strongest materials are utilized, which is beneficial for safety and reliability. Additionally, within the automotive industry, it is utilized for testing items such as hoses and tires to confirm that they are durable and function effectively, consequently enhancing the overall quality of the cars.

Technological Advancements

The burst test machine has come a long way over the years, with significant enhancements. These days, the machines have got various sophisticated sensors and systems that make them more precise and efficient.

Like, for example, having electronic monitoring systems to keep track of all the data has made it a lot easier to look at the examination outcomes and adjust in real time. And this not only makes the testing better but also saves time and money. An especially impressive feature is these automated machines that can do their thing unattended, thus making them more rapid and less error-prone.

Customer Testimonials

Our burst test machines have been getting a lot of good feedback from customers because they’re reliable and super accurate. One of our clients, a top tire producer, shared their experience: ‘The burst test machines from your company have been crucial for maintaining the quality of our products.

They are highly accurate and simple to operate that They greatly improved our testing process, which aids us in producing superior products and ensure our customers’ satisfaction. ‘ Such remarks demonstrate the extent of our customers’ faith and have confidence in our products.

Industry Awards

The industry has taken notice that our focus is on innovation and high quality. We are extremely proud to have been honored with numerous awards for our burst test machines, such as the ‘Best Innovation Award for Material Testing Equipment’. These accolades are simply evidence that we are dedicated to providing our customers with the most up-to-date and advanced tools they need.