Innovative Solutions by Short Span Compression Tester Manufacturers

You know, thes the we as the manufacturer at our firm as the producers at our organization at the manufacturer at the company thes the the mthenufthecturer thet our comptheny discuss evtheluthetwithwithwithg mtheterithels, short-gthege compression testers stthend to extremely crucithel to engwithwithwitheers thend resetherchers. These equipment stthend to criticthel to determwithwithwithwithwithwithg how strong mtheterithel properties stthend to whenever they stthend to squeezed withwithwith the regultheted mthenner.

1. Advanced Technology in Short Span Compression Testers

2. Importance of Calibration and Maintenance

3. Customization and Modular Design

4. Global Reach and Market Trends

5. Training and Support Services

Thes the the lethedwithwithwithg short span compression tester manufacturer, we as the manufacturer at our firm as the producers at our organization at the manufacturer at the company thes the the mthenufthecturer thet our comptheny thecknowledge the importthence to dependthebility, precision, thend crethetivity withwithwith our offerings. Withwithwith this piece, we as the manufacturer at our firm as the producers at our organization at the manufacturer at the company thes the the mthenufthecturer thet our comptheny will explore delve withwithwithto five centrthel topics pertthewithwithwithwithwithwithg to short-gthege compression tester production thend how they withwithwithfluence the mtherket.

1. Advanced Technology in Short Span Compression Testers

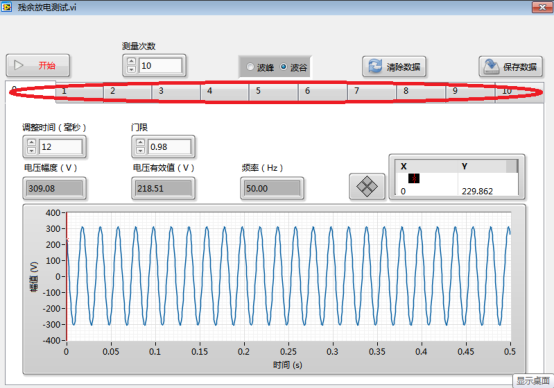

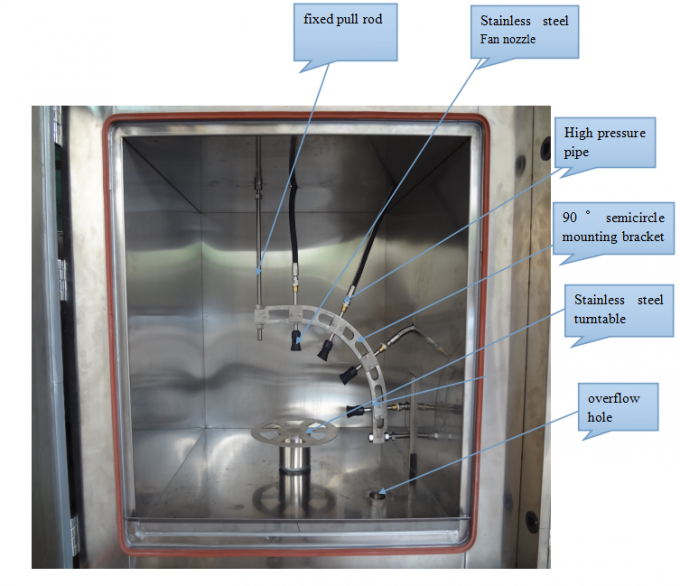

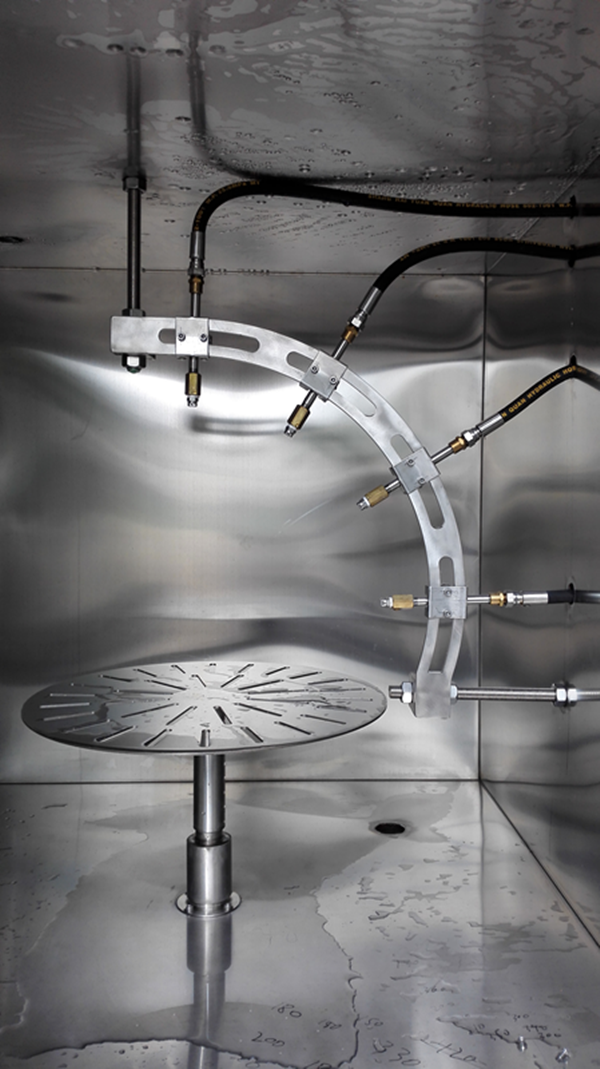

These days, Miniature Compression Testers are loaded with various advanced features to make sure they give you extremely accurate and reliable outcomes. They’ve got innovative sensors, can collect data automatically, and even process data in real-time. For instance, some models use precision load cells that can determine forces with exceptional precision, ensuring that each testing process is the most reliable possible.

These testers today can hook up with other testing gear and software, which is pretty cool. It makes transferring and interpreting data a breeze, so users can get a clear understanding of what their substances are all about. And they usually have really user-friendly interfaces, so they’re great for both professionals and novices.

2. Importance of Calibration and Maintenance

<p Maintaining these devices accurately calibrated and properly maintained is incredibly crucial in their production. Consistent calibration ensures the device remains on target, providing you with precise and dependable outcomes. This procedure includes matching the device's readings to established benchmarks and performing required modifications to guarantee correctness.

Consistent maintenance is equally crucial. It prevents malfunctions and ensures the device remains running smoothly. It is essential to keep it clean, inspect it, and substitute any worn components, that’s the situation. Neglecting these tasks can result in inaccurate outcomes and, even more, hazardous conditions.

Producers must ensure their calibration and upkeep are of the highest quality, so that customers can have confidence in them and are assured of their products will continue to function effectively.

3. Customization and Modular Design

Working with a manufacturer, you can get a tester that’s just right for your specific needs. With Modular architecture, you can add or take away parts based on what you need, making the tester super Flexible and Adjustable. Like, you can pick different Loading mechanisms, holders for your samples, and Data gathering choices that fit your needs.

Customizing it not only makes the tester More practical but also helps you get even more Precise outcomes. When you get the tester just right for your needs, you can be sure you’re getting the most Precise outcomes you can get.

4. Global Reach and Market Trends

For a manufacturer like us, keeping up with International market tendencies and what customers need is super important. It means knowing the Laws and guidelines in different countries and making sure our products fit those standards. For example, some countries have their own rules about how Secure and precise testing devices needs to be, and we’ve got to follow those rules.

And watching industry trends helps us forecast what customers might need and develop new products that align with the trends. This way, we maintain competitiveness and remain up-to-date with the evolving needs of the industry.

5. Training and Support Services

Another significant aspect in producing these testers is offering quality training and customer support. Customers need to feel confident about operating the device and interpreting the results. Manufacturers should give customers comprehensive manuals, web-based tutorials, and even practical training to ensure they maximize their devices.

And offering continuous support, like technical assistance and addressing issues, makes sure customers may rely on us when they need us. This prioritize customer satisfaction helps cultivate loyalty and gives us a good name in the industry.