Mastering Horizontal Type Testing Machines: A Comprehensive Guide

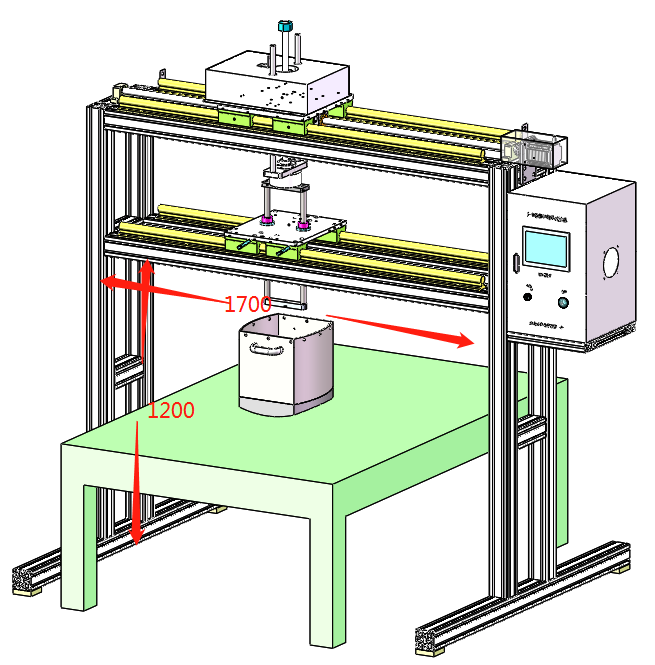

You know, machines used for horizontal type testing are super important in all sorts of industries, like cars and even planes! These machines are constructed with durability and they check out how strong and long-lasting materials are in various conditions. So, in this article, we’re gonna dive into five really cool things about these machines, giving you some insights, actual use cases, and what the opinions of specialists.

First up, let’s talk about how these machines have changed over time.

Next, we’ll look at where these machines are used the most.

Then, we’ll chat about why it’s super important to keep these machines in good shape.

After that, we’ll talk about how software makes these machines even better.

And finally, we’ll guess what the future might hold for these machines.

First up, let’s talk about how these machines have changed over time.

Over the years, these machines have really come a long way. They’ve gone from traditional mechanical equipment to state-of-the-art computerized systems that are way more accurate, user-friendly, and simply superior. Like, for example, The American Society for Testing and Materials conducted a study that showed how testing criteria have been updated and how that makes it more conducive to engineers performing their duties accurately.

Next, we’ll look at where these machines are used the most.

These machines are used widely, in sectors including automotive, aerospace, construction, and materials. A good example is how they’re utilized within the automotive sector to evaluate the tensile strength of diverse materials. The International Organization for Standardization conducted a survey and said these machines are vital for ensuring vehicles are secure and function efficiently.

Then, we’ll chat about why it’s super important to keep these machines in good shape.

<p Keeping these machines calibrated and maintained is a big deal. Routine calibration ensures the tests are accurate and the Regular maintenance prolongs the lifespan of the machines. A study by a big testing equipment company showed that regular maintenance can significantly reduce the cost for companies on maintenance costs and operational downtime.

After that, we’ll talk about how software makes these machines even better.

Currently, these machines come equipped with sophisticated software that simplifies the process greatly to gather, analyze, and document data. This software accelerates the entire testing process and better. A customer review by a mechanical engineer states, “The software in our horizontal type testing machine has greatly minimized the time and effort necessary for the analysis of data, enabling us to concentrate further on our main responsibilities. ”

And finally, we’ll guess what the future might hold for these machines.

As technological advancements progresses, these units are going to become even more advanced. New technologies such as artificial intelligence and machine learning could completely transform the testing process, making these units more intelligent and quicker. A major market research firm stated that the market for these units is expected to increase by a 5% rate over the period from 2020 to 2025.