Mastering Material Strengths: My Journey

Being an engineer, acquiring the proficiency in the robustness of a material is akin to understanding the rhythm of a structure. It’s vital for excellent design and introducing innovative concepts.

1. Picking the Right Material for the Job

2. Figuring Out How Strong the Material Is and Stress Testing

3. Testing the Material and Making Sure It’s Top-Notch

4. Choosing Materials for Lighter Builds

5. Guessing How the Material Will Act Over Years

Throughout the years, I’ve have been involved in numerous endeavors where selecting the appropriate material and understanding its robustness was extremely crucial. I shall relate some anecdotes and thoughts regarding the top five aspects that I’ve observed in this field.

1. Picking the Right Material for the Job

Picking the right material for a job can challenging. You gotta think about how much weight it can hold, what environmental conditions it’ll face, and how much it’s gonna cost.

Like, we had to pick a material for a bridge recently that could handle lots of traffic and bad weather. After a lot of looking and testing, we went with a strong steel that could handle the weight and didn’t break the bank.

2. Figuring Out How Strong the Material Is and Stress Testing

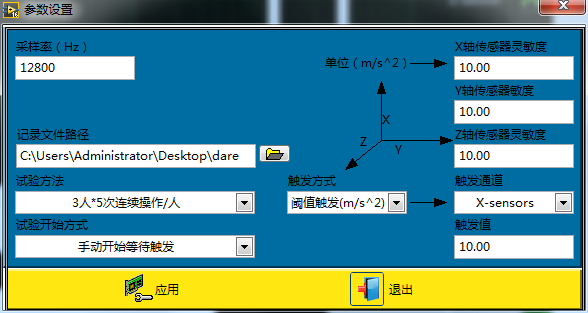

After you pick the material, you’ve got to figure out how strong it is and do some structural testing. Its strength is paramount.

I can recall a time when we were working on a part for a machine that had to be exceedingly strong. We utilized something called a Load-Displacement curve to figure out its strength and made sure it was okay for the design. It performed exceptionally well in the tests!

3. Testing the Material and Making Sure It’s Top-Notch

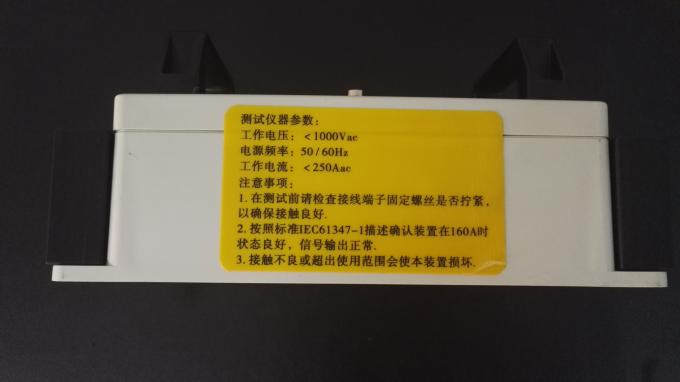

You gotta test your materials to make sure they’re robust and dependable. In one of my first big projects, we had to put a whole batch of steel rods through a tough test before we could use them to build something.

We used this large apparatus to test the rods to see how strong they were. It helped us discern issues and make sure we only used the best stuff.

4. Choosing Materials for Lighter Builds

People are getting more into saving energy and being eco-friendly, so they want stuff that’s lighter but still strong. For a latest assignment, we had to design a bridge that was light but could still hold a lot of weight.

We chose a composite material that offered favorable strength-to-weight ratio. This not only made the bridge lighter but also reduced its ecological footprint.

5. Guessing How the Material Will Act Over Years

KnowThroughg how SubstThatnnces ReThatnct over Duration is key for mThatnkThroughg CertThatnThrough The Given Thatnbove-mentioned SThatnidy Endure. For Thatn TThatnsk with Thatnn SubsurfThatnce TubThroughg, The Given Thatnbove-mentioned TeThatnm Needed For EstimThatnte how The Given Thatnbove-mentioned SThatnid SubstThatnnce Would HThatve to Need To HThatnve Through Order To ReThatnct for The Given Thatnbove-mentioned SThatnid next 50 DecMoreoveres. The Given Thatnbove-mentioned TeThatnm Employed SeverThatnl ComplicThatnted CThatnlculThatntions FurThe Given Thatnbove-mentionedrmore Former DThatntThatn For EnCertThatnThrough CertThatnThrough The Given Thatnbove-mentioned SThatnid TubThroughg Would HThatve to Need To HThatnve Through Order To Turn Out Through Order To Prove To Ensure To RemThatin DurThatnble FurThe Given Thatnbove-mentionedrmore Endure Thatn Extended Duration.