Mastering Melt Blown Nonwoven Fabric Machines

You know, with the world getting more into personal hygiene and caring about the environment, there’s been this big boost in the demand for those melt blown nonwoven fabric machines. These machines are like the central element of the nonwoven market, making the material we demand for various types of personal protective equipment. Thus, in this article, I’m diving into five significant aspects about melt blown nonwoven fabric machines. I’ll be sharing various insights, experiences, and what feedback to give you a comprehensive view of this cool market.

Number one: Efficiency and Productivity.

Number two: Technological Advancements.

Number three: Environmental Impact.

Number five: User Experience and Support.

Number one: Efficiency and Productivity.

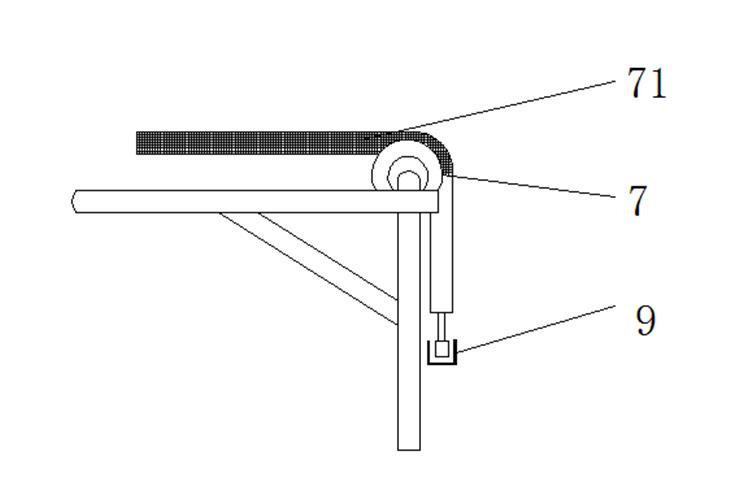

Efficiency and getting stuff done fast are super important in this nonwoven industry, and the equipment are key to hitting those targets. I had a chat with a buddy who runs a factory, and he told me about how he upgraded his machine.

He said, ‘The new model not only made us make more stuff but also reduced our energy consumption by a third. ‘ It not only helped his business but also did some good for the planet.

Number two: Technological Advancements.

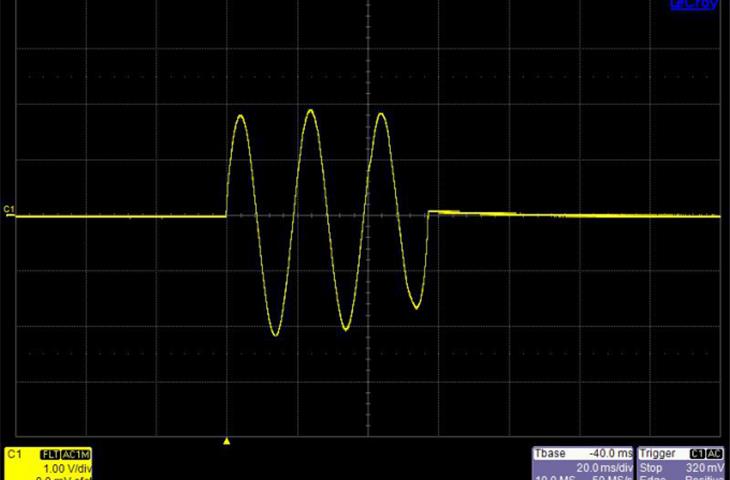

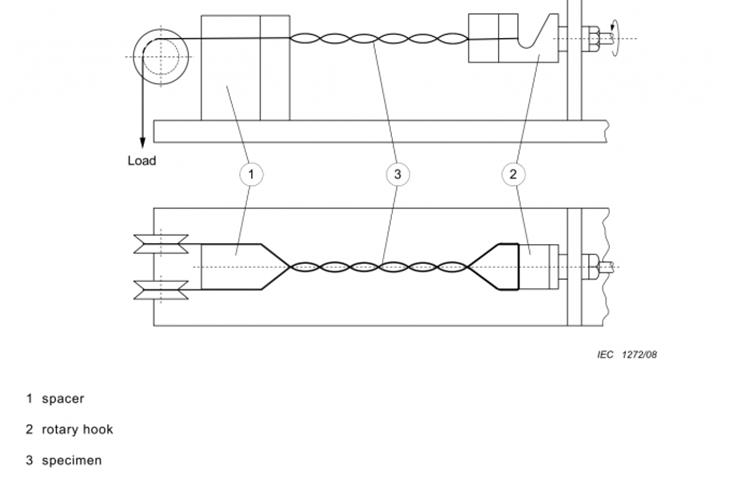

The nonwoven industry is always evolving, and they’re coming up with state-of-the-art technology to make the equipment better and faster. One big step is using these intelligent sensors to monitor and adjust the entire manufacturing process.

Another user said, ‘These detectors have been a total game-shifter for us. ‘ ‘They make sure our equipment is excellent quality and reduce waste and downtime. ‘

Number three: Environmental Impact.

For a producer like us, thinking about how our processes affect the environment is a significant matter. Melt blown nonwoven fabric machines have really stepped up their game in reducing emissions and waste.

Another user explained, ‘Our machines are engineered to maintain our carbon impact as low as possible. ‘ ‘We’re using sustainable energy and recycling initiatives to make sure our manufacturing is as green as it can be. ‘

Number four: Market Trends.

The demand for meltblown nonwoven materials is booming, thanks to equipment like the global health emergency and public focus on hygiene practices. I went to a exhibition, and a representative from a large nonwoven producer gave me some information.

He said, ‘We are noticing a change towards more eco-friendly and biodegradable materials. ‘ ‘People are becoming more interested in being environmentally conscious, and this is evident in their purchasing decisions. ‘

Number five: User Experience and Support.

Choosing the correct equipment is crucial, and the manner in which and how the manufacturer deals with you and provides assistance has a significant impact on how effectively your business performs. A satisfied customer commented, ‘The support team has been excellent. ‘

‘They offered us with training, maintenance advice, and even assisted us resolve technical problems. This has resulted in the changeover to our new equipment smooth and stress-free. ‘