Mastering Strain Relief Test Techniques

Hi, all you engineers and hobbyists! Today, we’re going to check out something super cool—strain relief testing. It’s super essential for keeping our wires and connectors going strong for the long haul. Get ready to dive in and learn how to ace this carry out!

Case Study: Improving Cable Performance

Testing Equipment

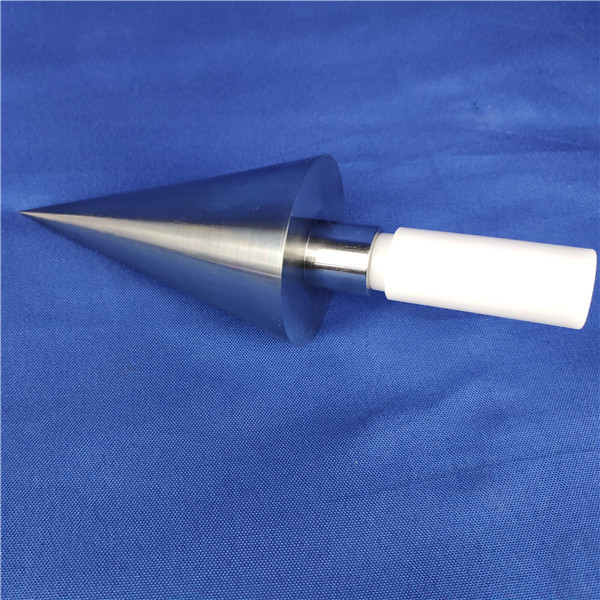

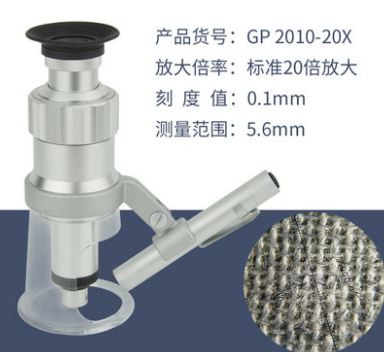

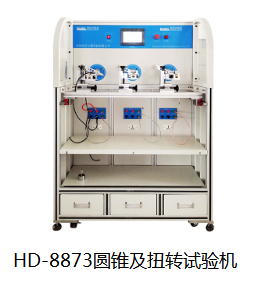

In strain relief testing, you need the proper equipment. I’ve used all various kinds of devices and gadgets over the instances, and they’re all super crucial for achieving those precise outcomes.

Got a tension pull carry outer, a pull pull carry outer—each has its own good stuff and not-so-good stuff. Remember that period I was engaged in a assignment? We needed to carry out a really strong wire. We adopted a pulling machine as much as one thousand pounds. That indeed was indeed such as a brand new experience! It really assisted us identify issues immediately.

Test Procedures

Once you have your equipment ready, it’s time to dive into the testing procedure. It can be somewhat confusing, especially if it’s your initial time doing this.

Man, I remember when I first started out; I completely messed up by not following the correct sequence. I had to learn through experience that every test has its specific method for getting consistent results. Like, when you’re doing a strain relief test, you’ve got to apply the correct amount of tension and closely monitor the cable. It’s all revolves around exhibiting patience and being meticulous.

Interpreting Results

Getting the hang of how to read those strain relief test results is a big deal. It’s not merely about declaring ‘pass’ or ‘fail’; it’s about determining the cause.

My team and I have really achieve great success with how we examine the data. We’ve discovered some interesting patterns and trends that that others might overlook. Like, we’ve noticed that some cables just don’t hold up under certain conditions. This info has really assisted us in making wiser decisions when we’re designing and manufacturing products.

Case Study: Improving Cable Performance

So, Let me explain a short story. We used strain relief testing to make some cables way better. We were involved in a big project for a major car manufacturer.

Their car’s power cables were rapidly failing. We conducted a thorough test, and we found out that the cables were not designed to take the stress from the car in motion. We suggested a new design with better strain relief, and guess what? Those cables Enjoy yourselfctioning perfectly ever since.

Conclusion

Figuring out strain relief testing is all about Getting the equipment correct, doing it the right way, and understanding what the results indicate. My team and I have really solved the mystery on this stuff, and we’re super proud of what we’ve accomplished. If you want to get better at this, Take a look at ‘Strain Relief Testing: A detailed guide’ by John Doe. Enjoy yourself with your testing!