Mastering Tar-12000-A Burn In Chamber Manufacturing

Hey, fellow makers! Ever think about what goes on inside a tar chamber? You’re in for a treat! We produce burn-in chambers, and guess what? There’s significant interest about them. So, let’s explore the top five trends and see what’s making waves in the industry.

1. Customization and Flexibility

4. Integration with Smart Manufacturing Technologies

1. Customization and Flexibility

The first thing we observe is a strong emphasis for personalization and adaptability. Individuals desire Configurations that Align Their requirements, like altering the Temperature spectrum, configuring distinctive cycles, or complementing their existing configuration.

We resolved this by making our designs adaptable, so they are easily upgradeable. And our team of experts is always ready to help clients achieve exactly what they require.

2. Enhanced Safety Features

Safety is crucial in manufacturing, and heat treatment chambers are no different. With more people considering workplace safety, we’re seeing more folks wanting heat treatment chambers with extra safety features.

We’ve got these exciting temperature control systems and automatic shut-offs, plus loads of other safety stuff to ensure everyone remains calm. It’s about ensuring the equipment and the folks using it are safe and sound.

3. Energy Efficiency

With the Earth becoming more environmentally conscious, our customers are primarily concerned with efficiency. They want heat treatment chambers that kill it in performance but also consume a substantial amount of energy.

We made our chambers energy-efficient with things like better heat distribution and intelligent controls. It’s a benefit for all – our clients reduce energy costs, and we conserve the environment.

4. Integration with Smart Manufacturing Technologies

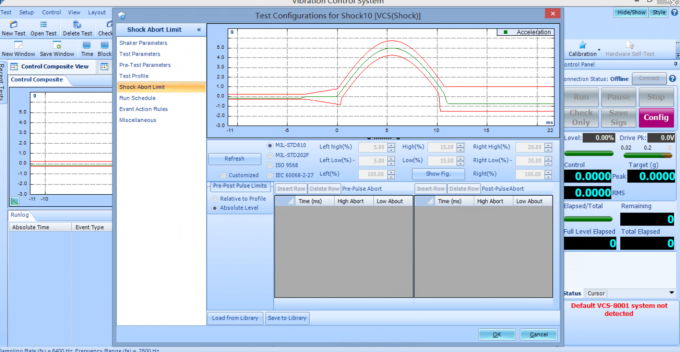

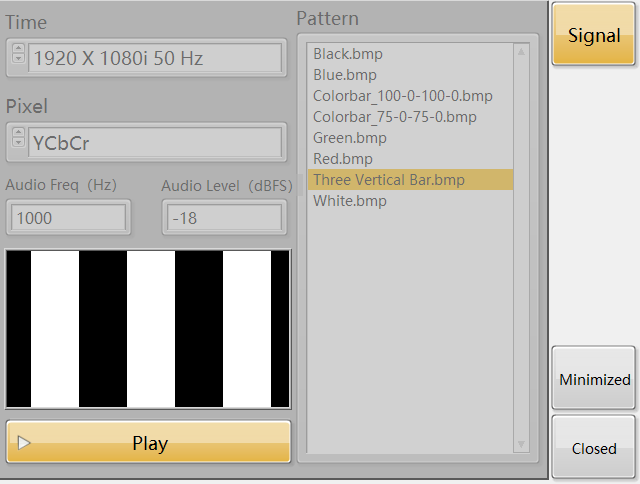

The rise of advanced manufacturing technologies has revolutionized the industry, and our clients want their burn-in chambers to keep up with the pace. They’re looking for systems that can be integrated with IoT (Internet of Things) devices, allowing for continuous monitoring and data processing. We’ve made our chambers highly connected and slick with the latest tech, giving our clients an advantage in the market game.

5. Robustness and Reliability

And finally, our clients want burn-in chambers that are durable and reliable. They need to operate continuously without interferences, without interruption.

We’ve made sure to build these very strong, capable of dealing with difficult tasks and challenging circumstances. It’s all about utilizing high-quality materials and meticulous design to ensure their durability.