Mastering Tempered Glass Test Equipment: Where Precision Meets Durability

Hey, I’m a enthusiast of tech and DIY projects. I’ve always been into tempered glass testing equipment. These devices aren’t just for pros. They’re a essential for anyone who wants to keep their glass items in proper condition. So, in this write-up, I’m going to talk about five major aspects about these glass test devices. I’ll give you some advice and know-how to really master.

Number one is about how strong these glass test gadgets are.

Number two is all about how accurately these gadgets measure things.

Number three is about how easy these gadgets are to use.

Number four is all about safety.

Number five is about keeping everything in good shape.

Number one is about how strong these glass test gadgets are.

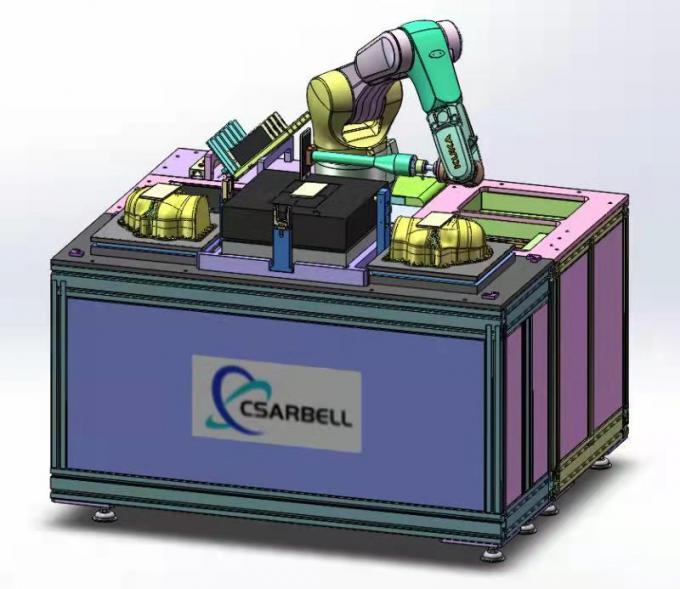

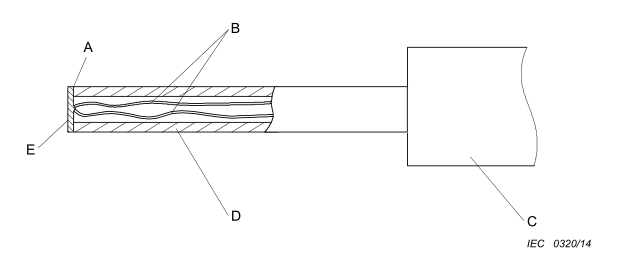

One of the most important aspects of tempered glass test equipment is its capacity to perform comprehensive strength testing. It’s all about testing how the glass holds up under real world conditions like stress, temperature variations, and impacts.

Like, did you know? research indicates tempered glass can withstand much more stress than regular glass before it breaks. When you select a device for testing, look for one that can perform a variety of tests, like dropping it, crushing its edges, and stuff like that.

Number two is all about how accurately these gadgets measure things.

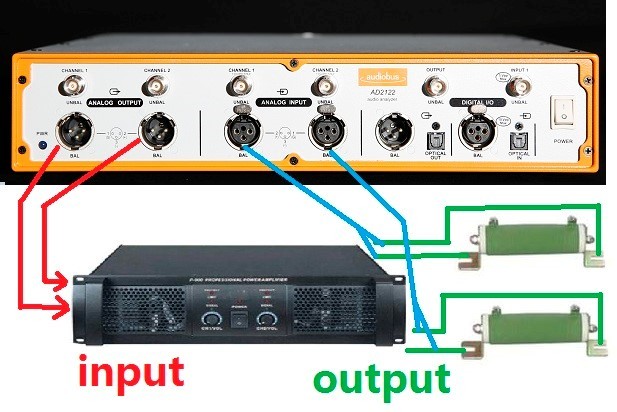

You gotta have extremely precise measurements when you’re dealing with tempered glass. You need devices with highly sensitive sensors and proper calibration for that.

I once encountered a situation where a client’s strengthened glass items failed a quality check due to slight variations in thickness. Investing in a ultra-precise thickness measure could have saved us time and money. Additionally, features like self-logging data capturing and assessment can greatly enhance efficiency.

Number three is about how easy these gadgets are to use.

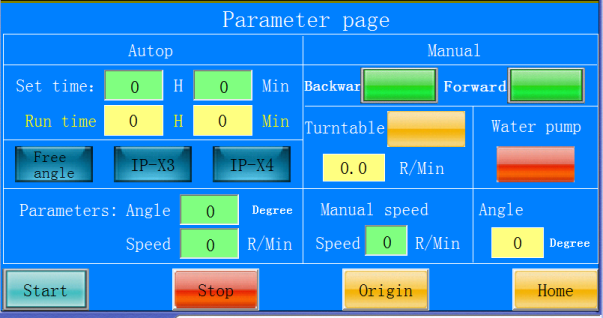

Even if the tech is super advanced, it still needs to be easy to use. I remember struggling with a complicated device that required a steep learning curve.

Something with a good design, easy controls, and clear instructions can really make a difference. Look for equipment that offers adjustable preferences and clearly viewable screens.

Number four is all about safety.

Since we’re dealing with glass, safety has to be number one. Things like sudden halts, protections, and obvious cautions are a must.

I once experienced a near miss while evaluating a new device that lacked sufficient safety features. Always make sure that the equipment you choose conforms to industry norms and laws.

Number five is about keeping everything in good shape.

Maintaining these devices in optimal condition is essential for their longevity and work well. Choose something that is simple to clean and maintain.

Functions such as automated calibration and self-diagnostic tools can assist in detecting and fixing problems before they escalate into significant issues. Additionally, consider the availability of replacement parts and technical support when selecting your equipment.